Device and technique of developing scale and corrosion inhibitor using organic waste

A technology of scale and corrosion inhibitor and organic waste, applied in the field of preparation of scale and corrosion inhibitor, can solve the problem that divalent ions are prone to gelation, the concentration ratio is low, and cannot be adapted to high hardness, high alkali, and high concentration ratio. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

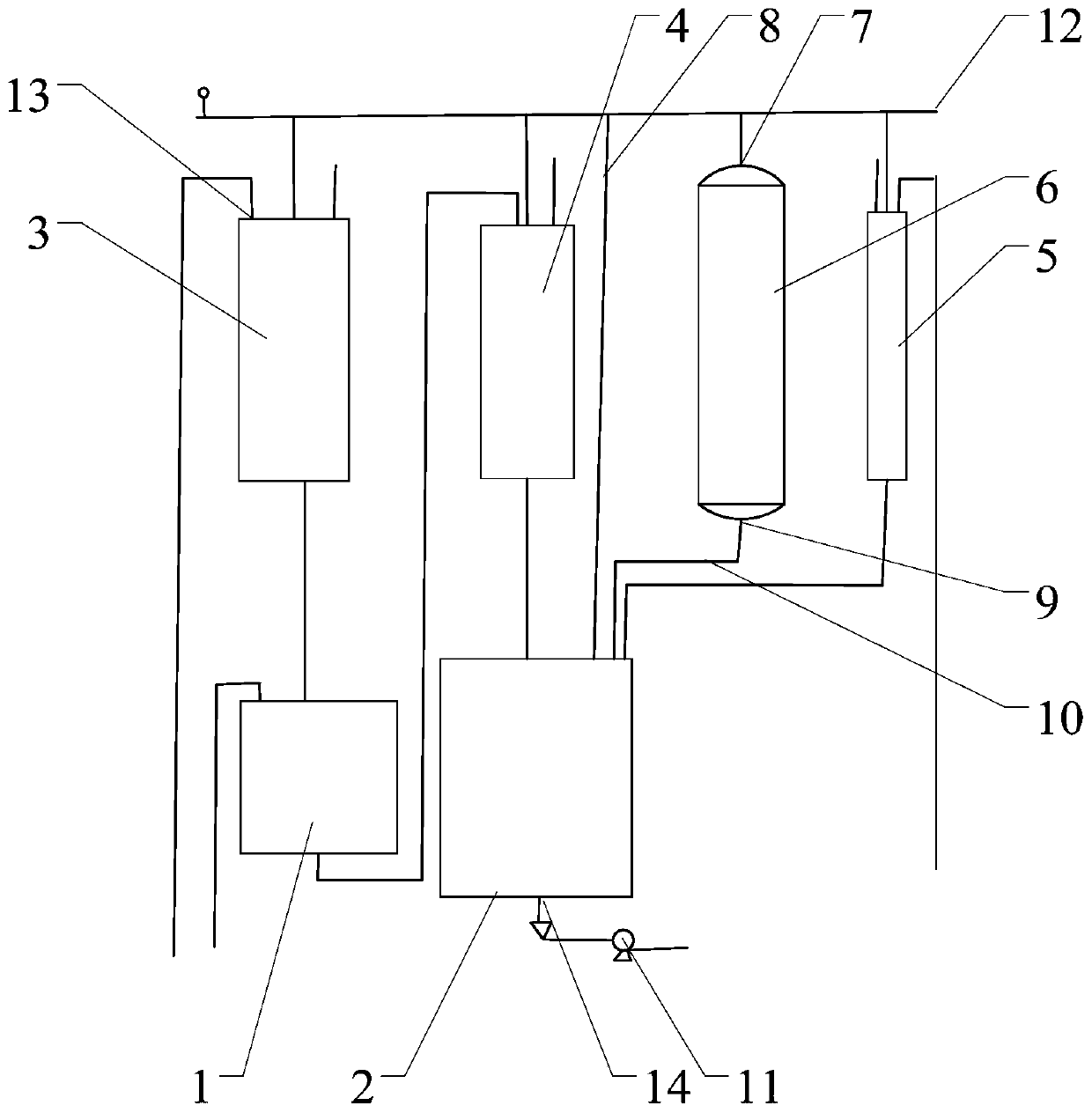

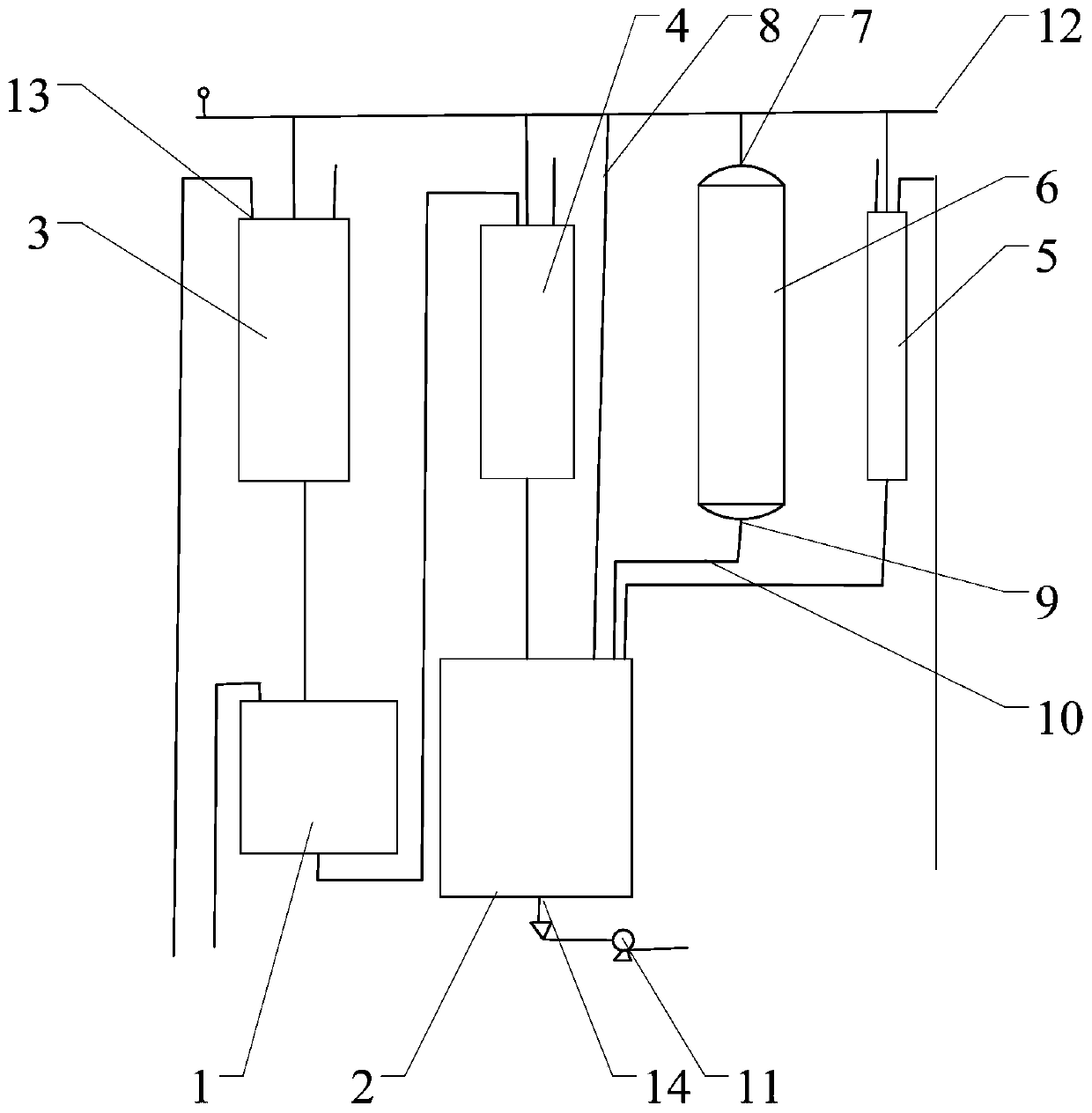

[0025] figure 1 It is a schematic structural diagram of an embodiment of a device for developing scale and corrosion inhibitors using organic waste according to the present invention. As shown in the figure, the present invention provides a device for developing scale and corrosion inhibitors using organic waste, including a first Reactor 1, the second reactor 2, the first elevated tank 3, the second elevated tank 4 and the third elevated tank 5, a graphite condenser 6 is arranged between the third elevated tank 5 and the second elevated tank 4, and the graphite condenses The upper end of the device 6 is provided with an air inlet 7, and the air inlet 7 is connected with the second reaction kettle 2 through an air inlet pipe 8, and the lower end of the graphite condenser 6 is provided with a liquid outlet 9, and the liquid outlet 9 is connected with the second reactor 2 through a liquid outlet pipe 10. The two reaction kettles are connected. After the reaction in the second re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com