Integrated production line for covering and detecting relay base

A relay and production line technology, applied in the field of integrated relay base sealing detection production line, can solve the problems of unable to reassemble the base, waste of the base, increase the production cost of the relay base, etc., so as to avoid the waste of difficult rework and increase the placement efficiency. The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

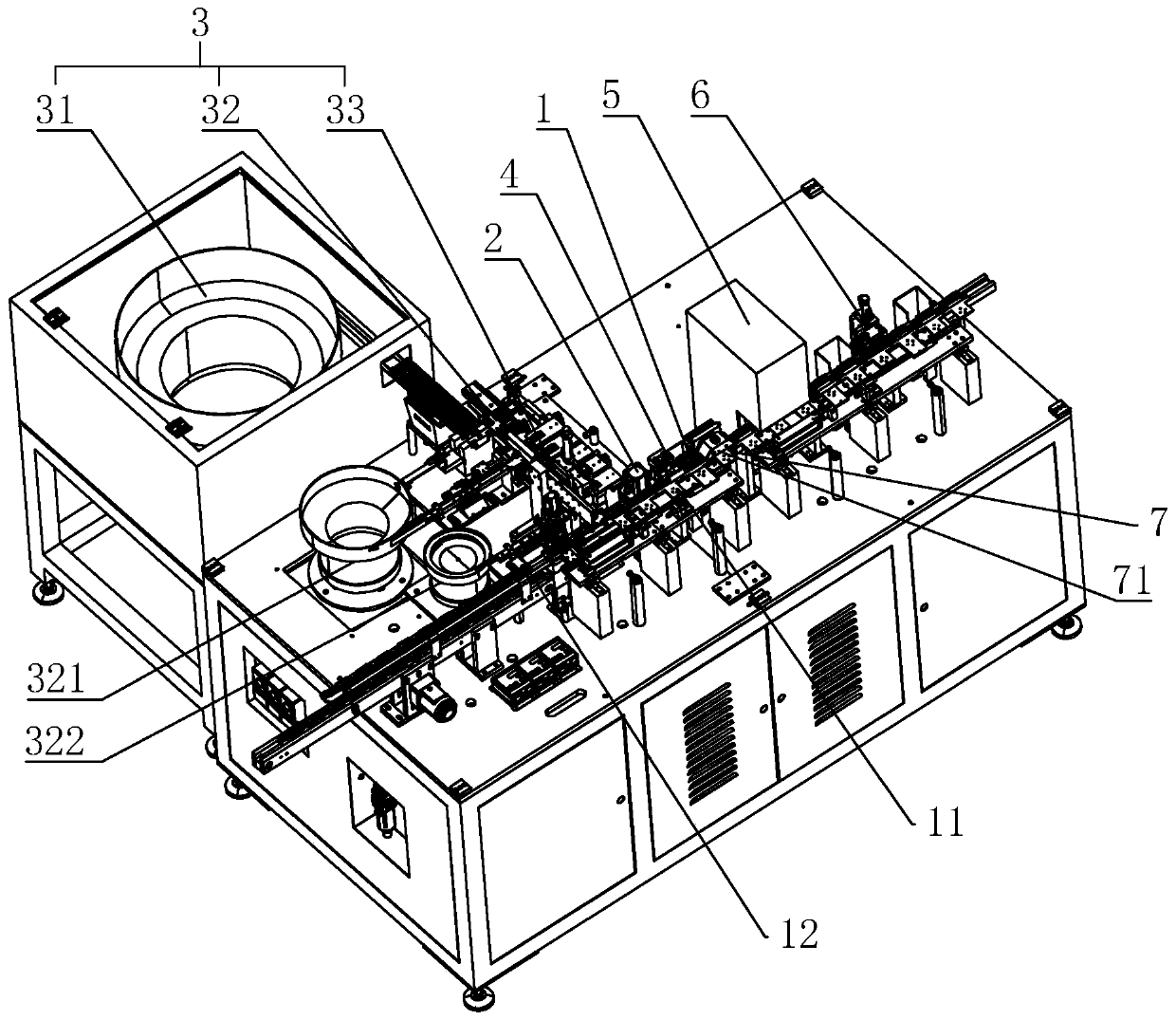

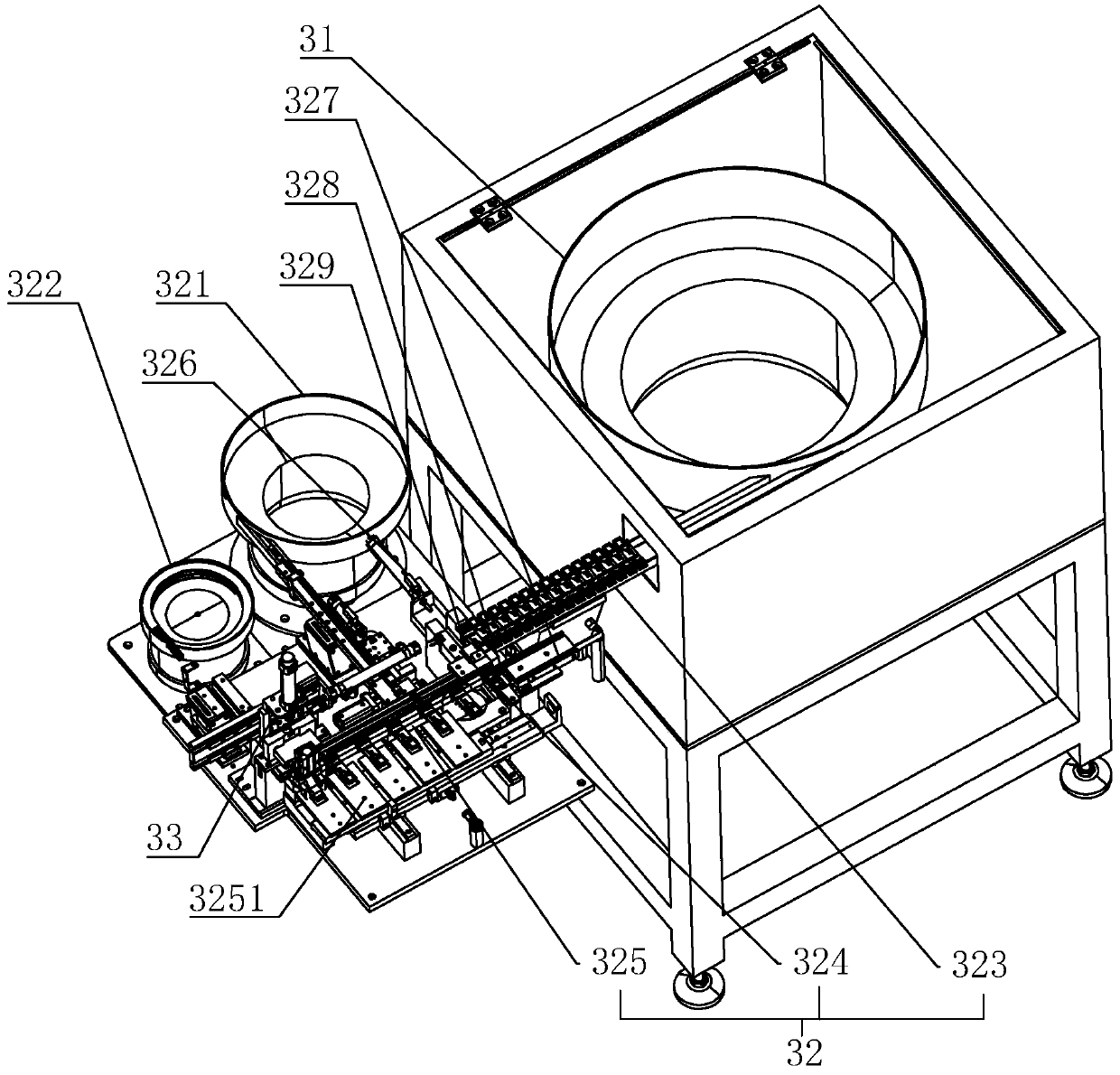

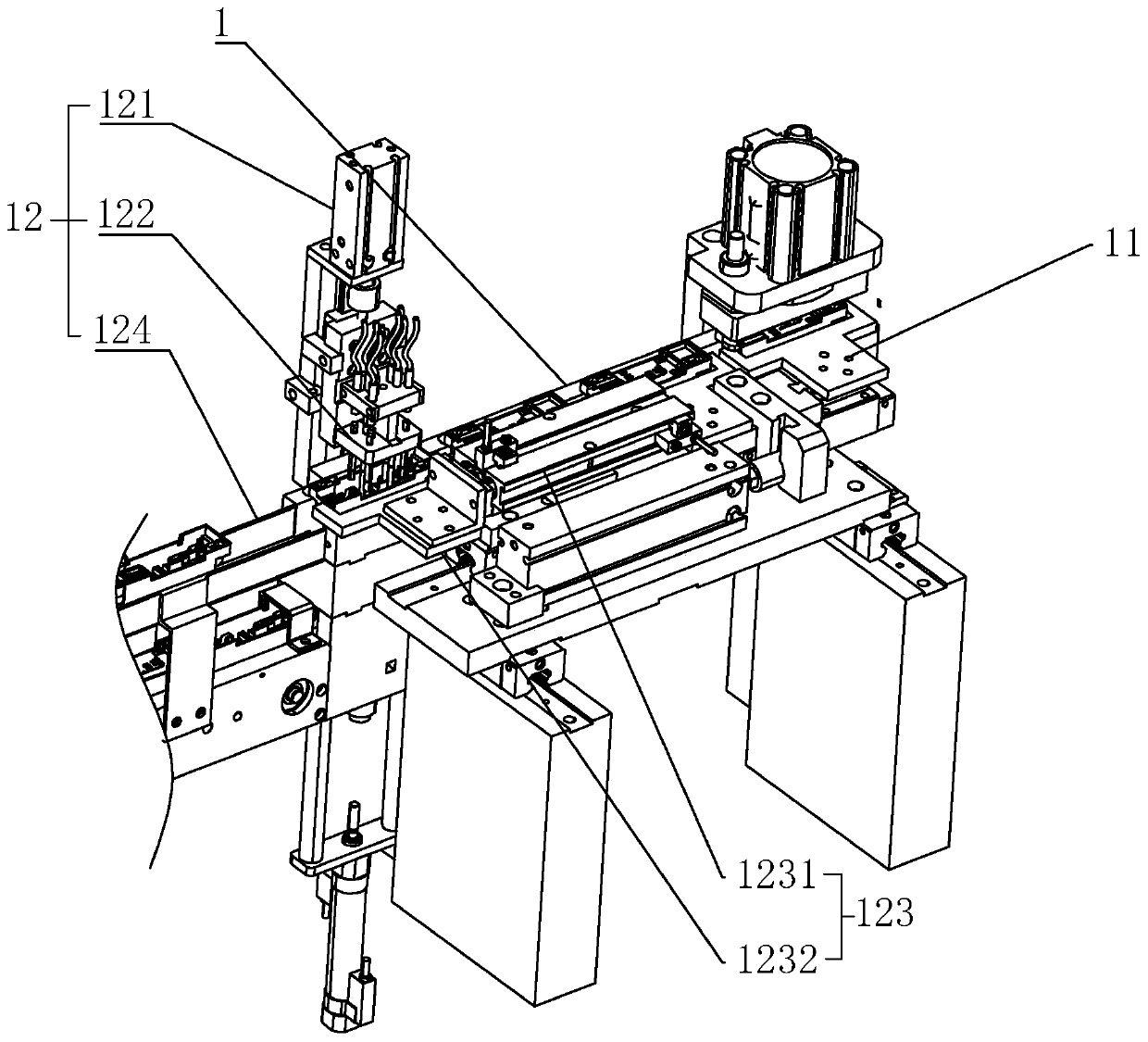

[0021] refer to Figures 1 to 4 As shown, an integrated production line for relay base capping detection in this embodiment includes a conveying track 1, a capping device 2, a capping device 3 and a marking device 8, and the capping device 3 and capping device 2 are arranged On one side of the conveying track 1, one end of the conveying track 1 is connected to the previous station. After receiving the shell assembled by the previous station, it gradually passes through the cap feeding device 3 and the capping device 2. When the shell passes through the cap feeding device 3, the cap feeding device 3 places the cap on the shell, and then presses it through the capping device 2, and after the pressing is completed, it is input into the marking device 8 for marking, and the transmission track 1 connects One end of the previous station is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com