Electronic cigarette assembly production line

A production line and electronic cigarette technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low degree of automation, large space occupation, and many single equipment, saving workshop space, easy implementation, and transportation. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

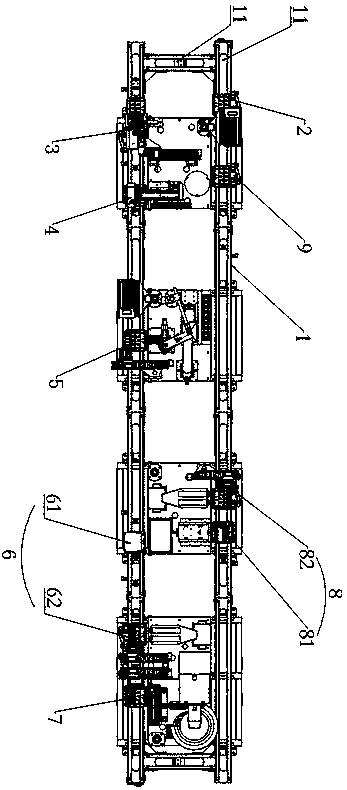

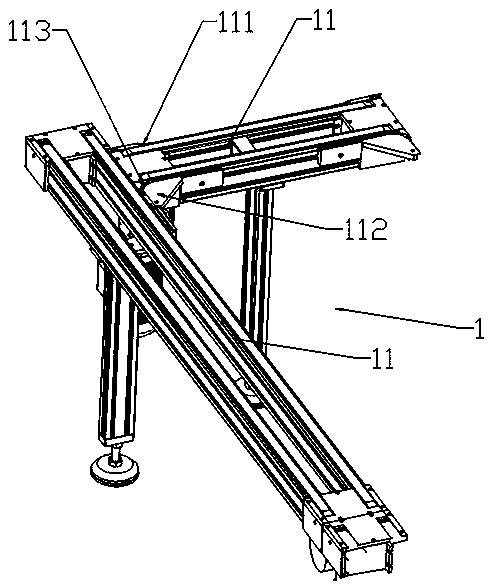

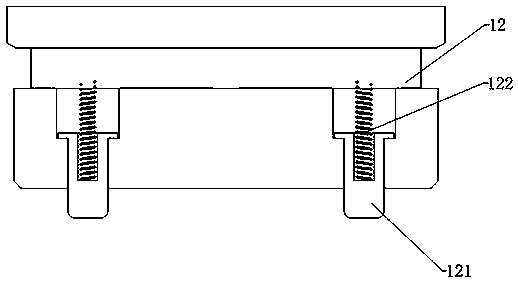

[0031] refer to Figure 1~13 , an electronic cigarette assembly production line, used for the assembly of electronic cigarettes. The electronic cigarette assembly production line includes a conveying device 1 and a feeding device 2 arranged along the conveying device 1, a deviation correcting device 3, an oil filling device 4, a rubber plug loading device 5, a resistance testing device 6, a cigarette holder device 7, and an air tightness testing device 8 And unloading device 9. The feeding device 2 is used to feed the semi-finished cigarette holders to the conveying line 11, and the unloading device 9 passes through the deviation correcting device 3, the oil filling device 4, the rubber stopper device 5, the resistance testing device 6, the cigarette holder device 7 and the air tightness detection device 8 The cost of assembly and processing Cigarette holders are loaded and unloaded from the conveyor line 1. The feeding device 2 and the unloading device 9 can adopt structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com