A ptfe-coated needle felt

A technology of needle-punched felt and film coating, applied in the field of needle-punched felt, can solve the problems of low structural strength of PTFE needle-punched felt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

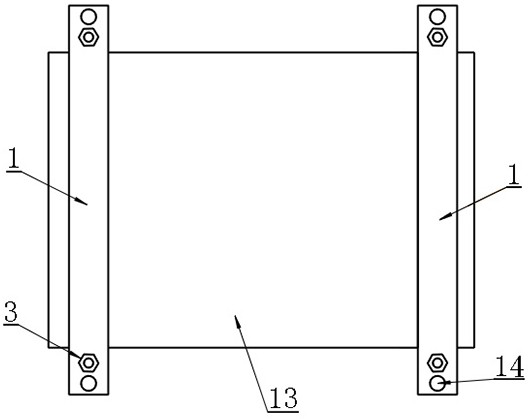

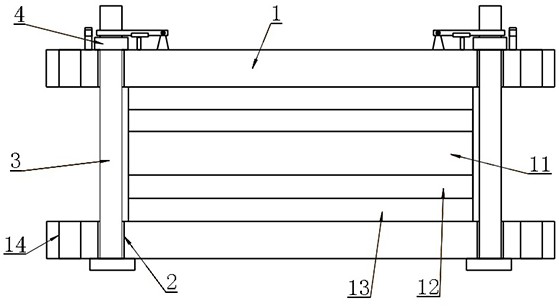

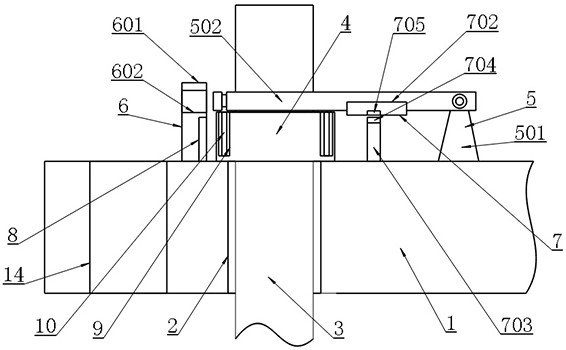

[0025] Example: as attached figure 1 , 2 , 3, 4, 5, 6 and attached Figure 7 As shown, a PTFE-coated needle-punched felt includes a PTFE net base layer 11, a heat insulation cotton layer 12 arranged on both sides of the PTFE net base layer 11, and a PTFE coating layer arranged on the heat insulation cotton layer 12. The multi-layer needle felt structure composed of film layer 13 also includes two pairs of clamping plates 1 arranged on both sides of the side of the multi-layer needle felt structure and used for clamping and fixing. The clamping hole 2 on the end of the board 1 is exposed, and the bolt 3 and the nut 4 arranged on the clamping hole 2 are plugged in, bonded and arranged on the PTFE coating layer 13 and rotated and compressed after being hinged. The nut 4 is in the form of a rotating plate unit 5 used to increase the structural stability of the multi-layer needle felt, which is bonded and arranged on the PTFE coating layer 13 and passes through the rotating plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com