Novel embossing mechanism of forming box embossing machine

An embossing machine and embossing technology, applied in decorative arts, painting tools, embossed decorative parts, etc., can solve the problems of troublesome replacement of hydraulic embossing machines, different embossing depths, etc., to improve the yield and production efficiency, The effect of uniform embossing, improving indentation effect and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

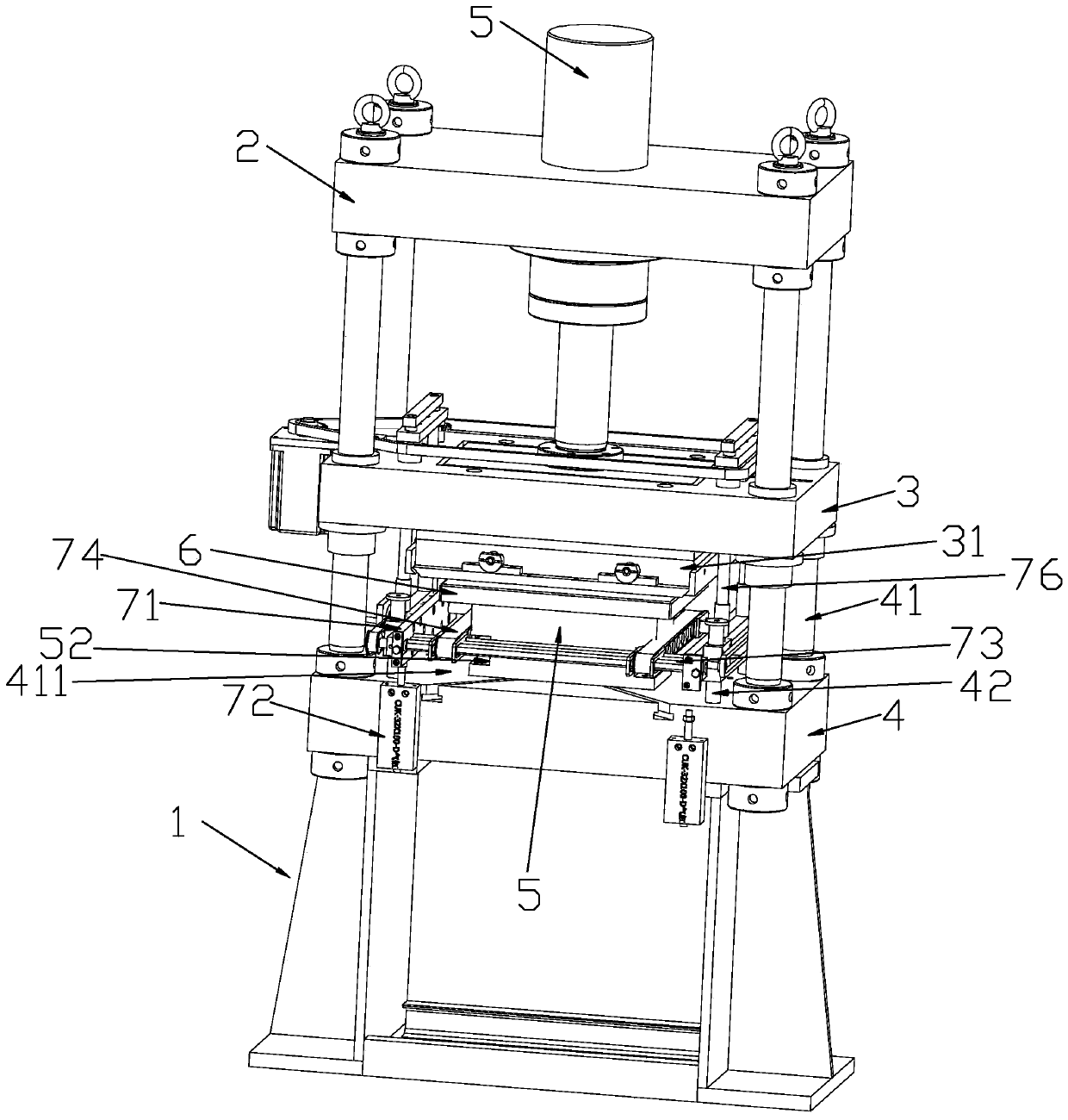

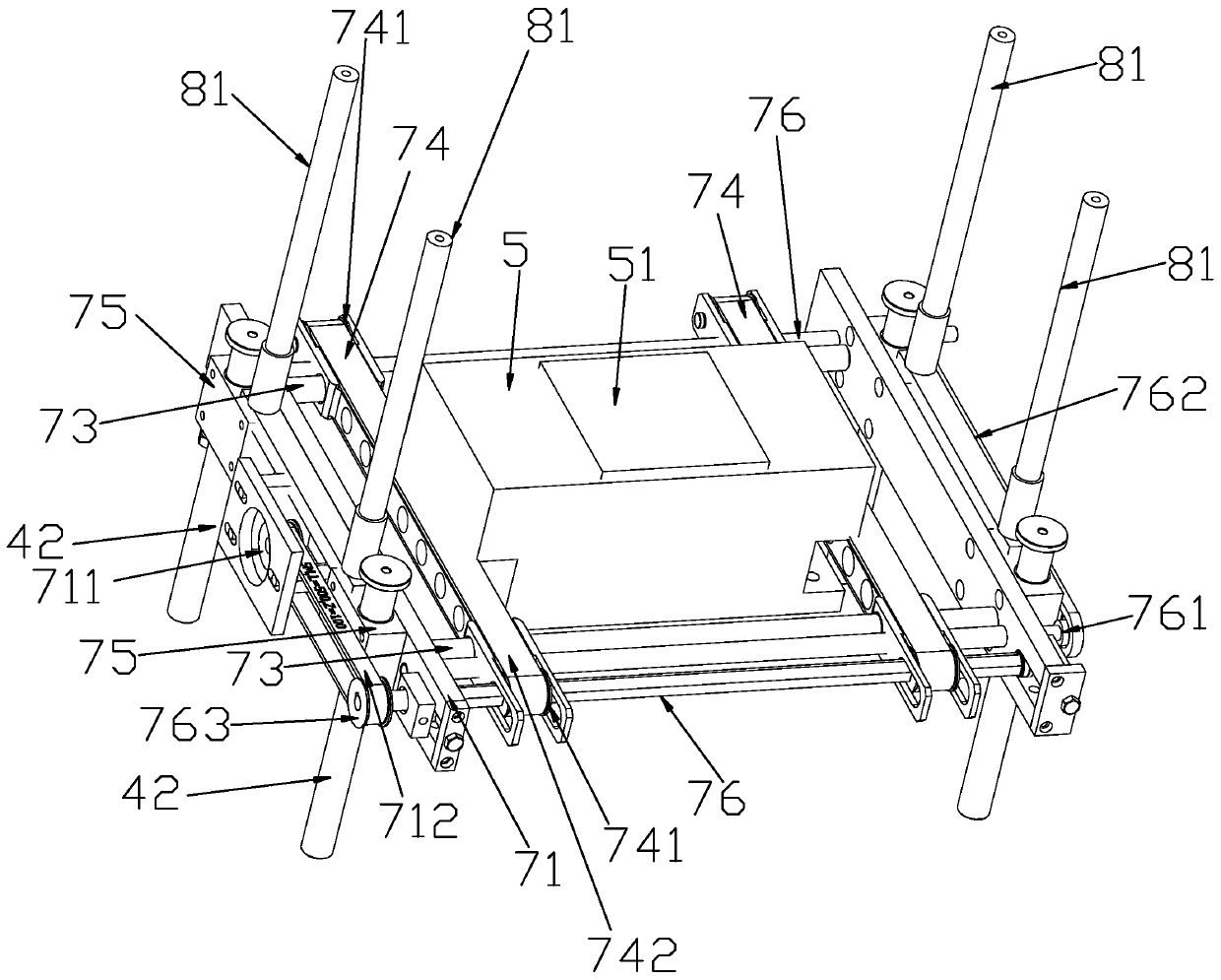

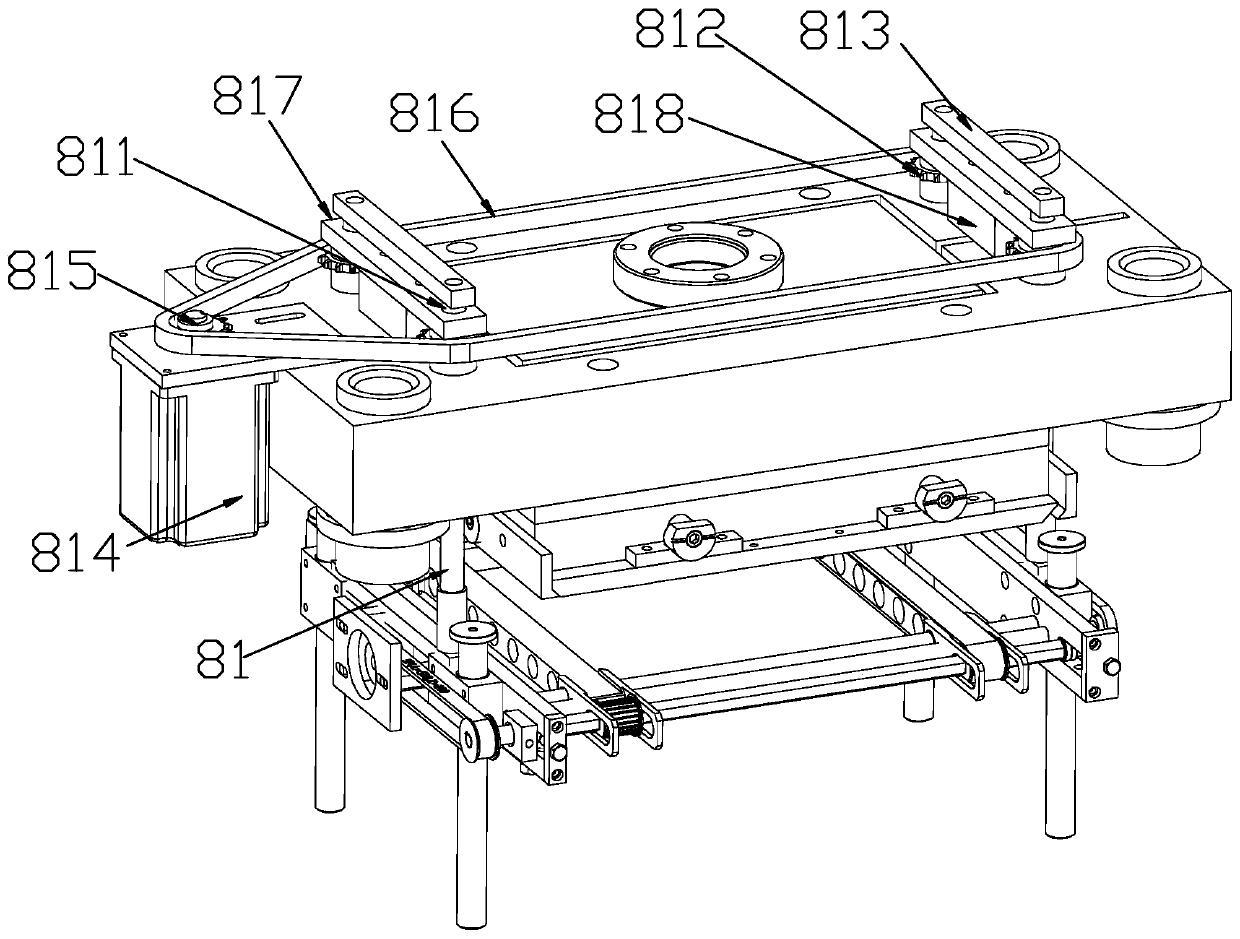

[0018] see Figure 1-Figure 3Shown: a new embossing mechanism of a forming box embossing machine, including a support frame 1, an upper beam 2, a movable beam 3 and a lower beam 4, the lower beam 4 is set at the end of the support frame 1 away from the ground, and the lower beam 4 There are four columns 41 on the top, the movable beam 3 and the upper beam 2 are sequentially installed on the columns 41, the oil cylinder 5 is fixed on the upper beam 2, the piston, the piston rod and the movable beam 3 are rigidly connected into one body by flanges and bolts. A workbench 5 is arranged between the crossbeam 3 and the lower crossbeam 4, an upper embossing die 31 is connected to the end of the movable crossbeam 3 facing the lower crossbeam 4, and a lower embossing die 31 opposite to the upper embossing die 31 is arranged in the workbench 5 51, the pressed workpiece 6 is set on the lower embossing mold 51, and there is a device between the movable beam 3 and the lower beam 4. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com