A kind of multi-layer structure defluorination agent and its preparation method and application

A multi-layer structure, fluoride removal technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. The problem of high equipment requirements, to achieve good fluorine removal effect, easy separation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

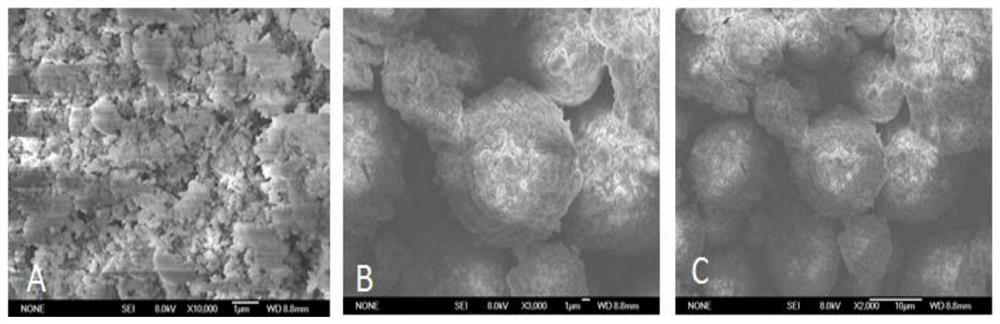

[0042] Preparation of fluorine-removing materials at different heating temperatures

[0043] 1. Preparation of fluoride removal materials

[0044] In the first step, add 5.0 g of nano-CaCO to the round bottom flask 3 , 0.2g polyethylene glycol and 0.2g surfactant sodium dodecyl sulfonate, then measure 100ml of water and add it to a round bottom flask, stir and disperse fully for 30min, then add the monomer DMAEA dissolved in the initiator, wherein the initiator It is dimethyl azobisisobutyrate, the dosage is 0.7g, and the dosage of monomer is 2ml, continue to stir and disperse;

[0045] In the second step, after stirring for 30 minutes, the temperature was raised to 50°C, and 5.0 g of vinyl monomer acrylamide was added to the reaction vessel, and the temperature control reaction was continued for 30 minutes;

[0046]In the third step, the temperature is raised to 50°C, 55°C, 60°C, 65°C, 70°C, 75°C, and the ethylenic monomer styrene dissolved with the initiator is added. The ...

Embodiment 2

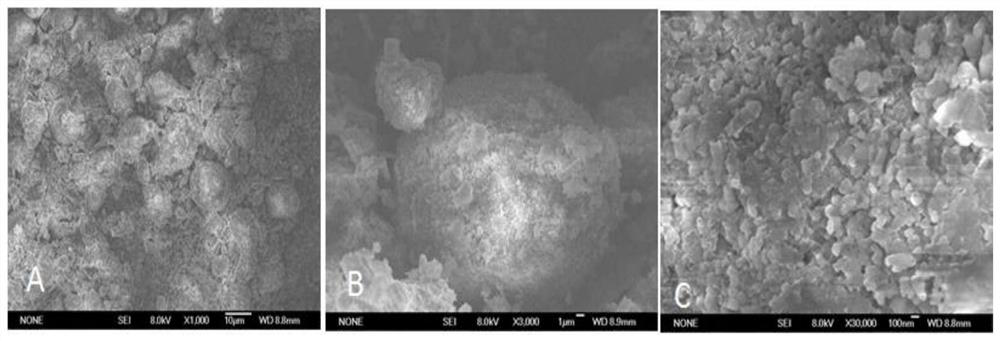

[0054] 1. Preparation of fluoride removal materials

[0055] In the first step, add 5.0 g of nano-CaCO to the round bottom flask 3 1. Add calcium phosphate 0.1g, 0.2g, 0.3g, 0.4g, 0.5g, 0.6g and 0.2g of surfactant sodium dodecylsulfonate respectively, then measure 100ml of solvent water into the round bottom flask, stir and disperse for 30min Finally, add the monomer DMAEA that dissolves initiator, initiator is dimethyl azobisisobutyrate, consumption 0.7g, monomer DMAEA consumption 2.0ml, continue to stir and disperse;

[0056] In the second step, after stirring for 30 minutes, the temperature was raised to 50°C, and 5.0 g of ethylenic monomer acrylamide was added to the reaction vessel, and the temperature control reaction was continued for 30 minutes;

[0057] In the third step, raise the temperature to 70°C, add the ethylenic monomer styrene dissolved with the initiator, the initiator is dimethyl azobisisobutyrate, the dosage is 0.7g, the dosage of styrene is 7ml, and then...

Embodiment 3

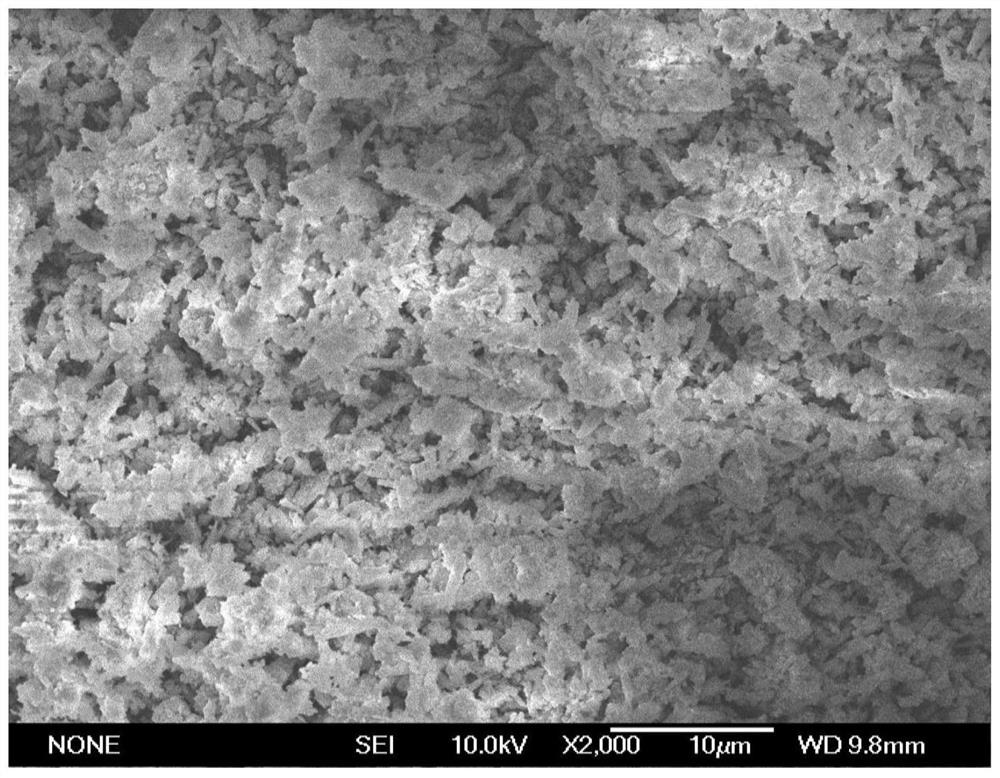

[0064] Preparation of fluorine-removing materials with different monomer DMAEA dosages

[0065] 1. Preparation of fluoride removal materials

[0066] In the first step, add 5.0 g of nano-CaCO to the round bottom flask 3 , 0.2g polyethylene glycol and 0.2g surfactant sodium dodecyl sulfonate, then measure 100ml of solvent water and add it to a round bottom flask, fully stir and disperse for 30min, then add monomer DMAEA 0ml dissolved in initiator, 1ml, 2ml, 3ml, 4ml, 5ml, 6ml, the initiator is dimethyl azobisisobutyrate, the dosage is 0.7g, continue to stir and disperse;

[0067] In the second step, after stirring for 30 minutes, the temperature was raised to 50° C., and 5.0 g of vinyl monomer acrylamide was added into the reaction vessel. Continue temperature control reaction for 30min;

[0068] In the third step, raise the temperature to 70°C, add the ethylenic monomer styrene dissolved with the initiator, the initiator is dimethyl azobisisobutyrate, the dosage is 0.7g, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap