Digging-rake-type rotary trash removing machine

A cleaning machine and rake-type technology, applied in the field of water conservancy cleaning equipment, can solve the problems of low work efficiency, limited range of things to grab, and inability to realize elastic adjustment, etc., to achieve effective dumping, simple structure, efficient and fast digging and raking The effect of formula work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

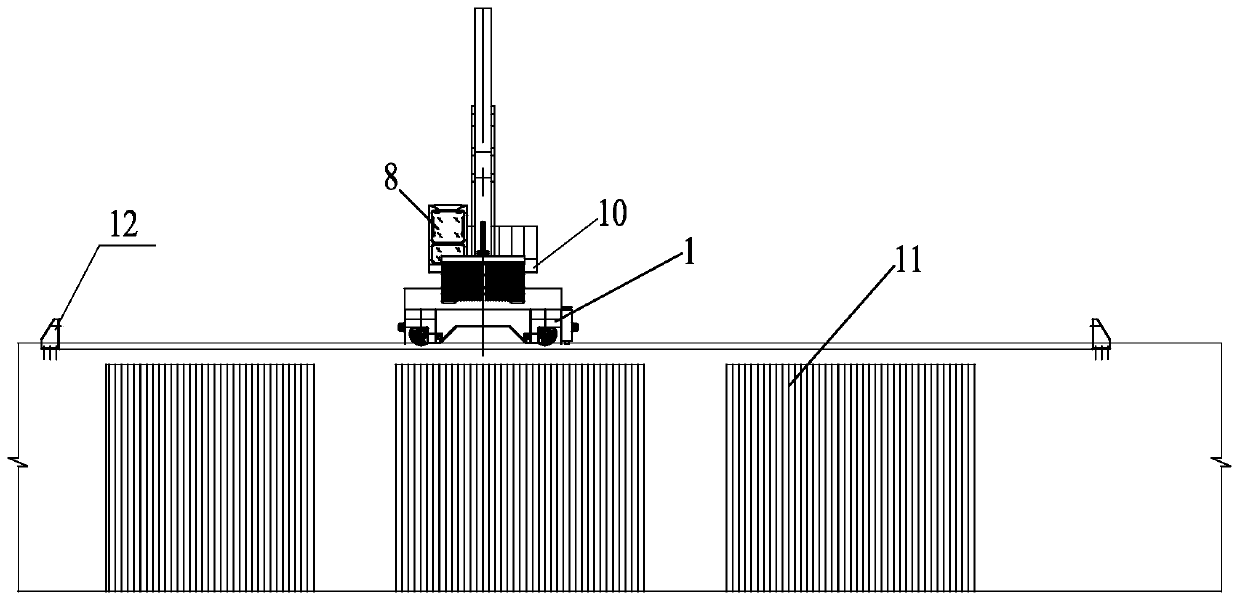

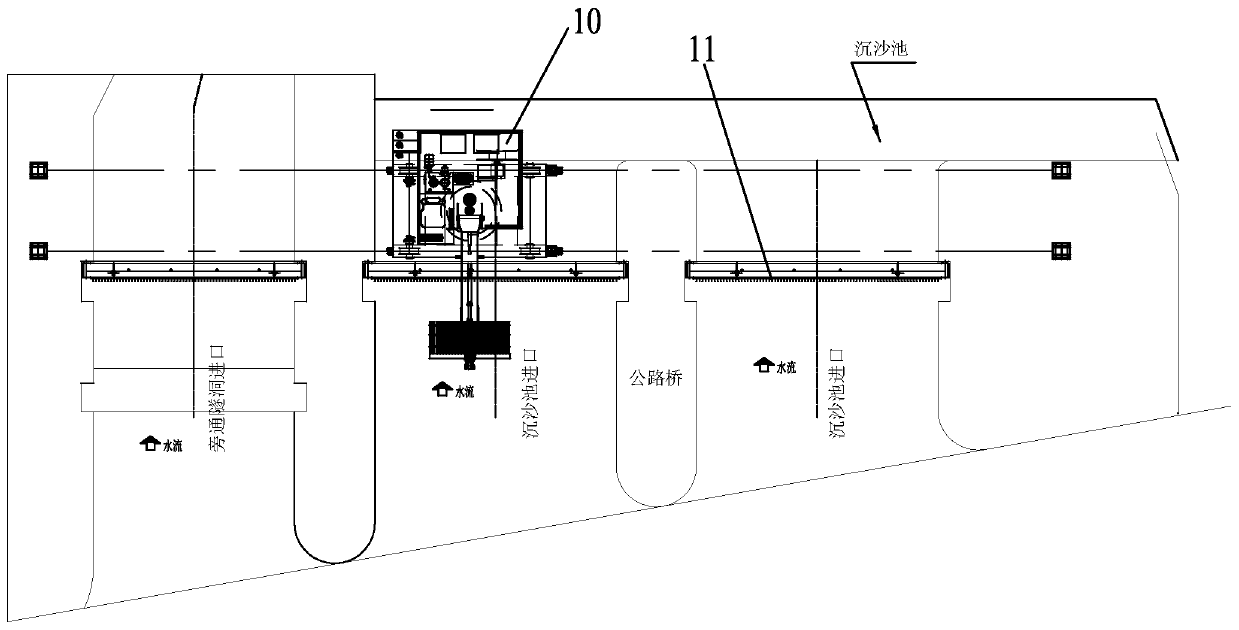

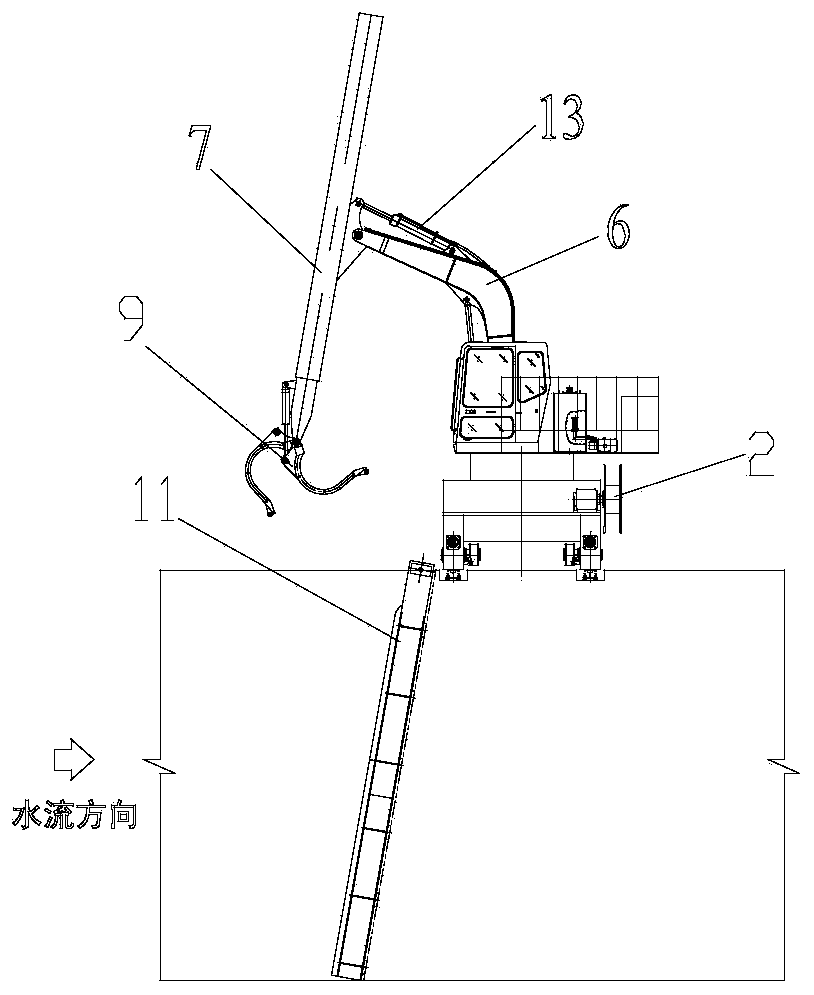

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0031] Figure 1~18 Including hydraulic traveling mechanism 1, buffer 1-1, rail sweeping plate 1-2, driven wheel assembly 1-3, travel switch 1-4, traveling frame beam 1-5, rail clamping device 1-6, driving wheel Components 1-7, connecting beams 1-8, power supply cable reel 2, hydraulic system 3, slewing platform 4, main platform 4-1, slewing support 4-2, platform railing 5, boom assembly 6, boom rod 6 -1. Lower hinge part 6-2, upper hinge part 6-3, telescopic arm assembly 7, first hinge part 7-1, second hinge part 7-2, telescopic arm guide rod 7-3, first stop Part 7-4, telescopic outer rod 7-5, second limiter 7-6, connecting seat 7-7, telescopic arm shell 7-8, telescopic arm inner arm 7-9, cab 8, rake bucket 9 , lifting lug 9-1, square pipe 9-2, rake tooth 9-3, roller 9-4, rake bucket telescopic cylinder 9-5, rotary arm type cleaning machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com