Quantitative multi-station automatic casting machine and working method thereof

An automatic pouring and multi-station technology, which is applied in the direction of manufacturing tools, metal processing equipment, and equipment for supplying molten metal, etc., can solve the problems of low pouring efficiency and difficulty in controlling the pouring amount of a single pouring object, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

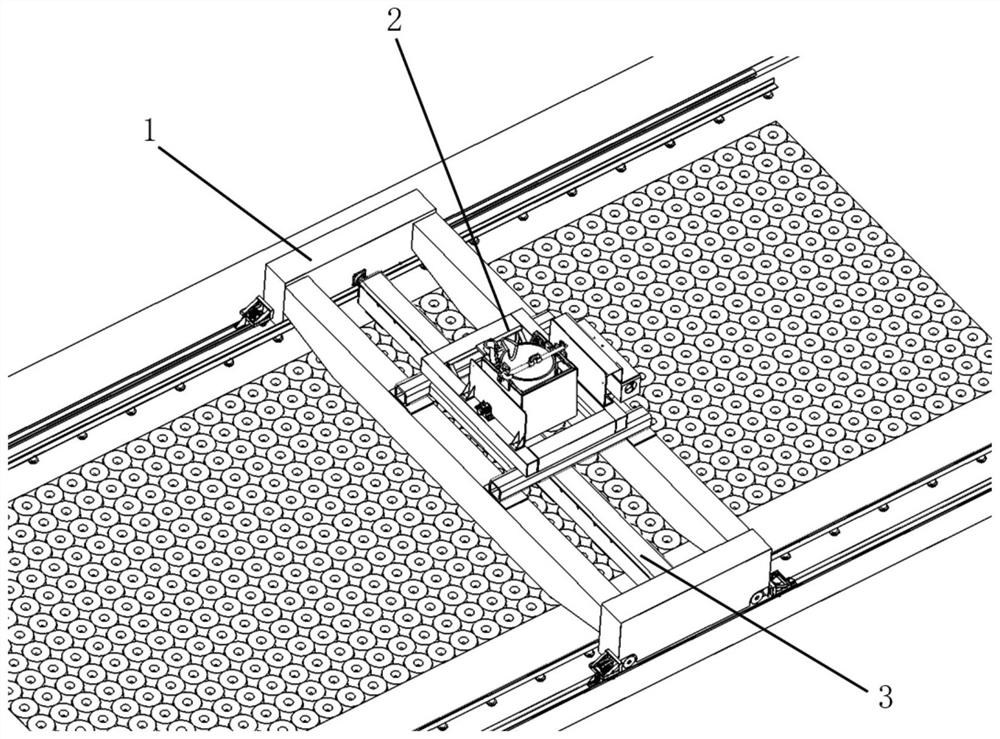

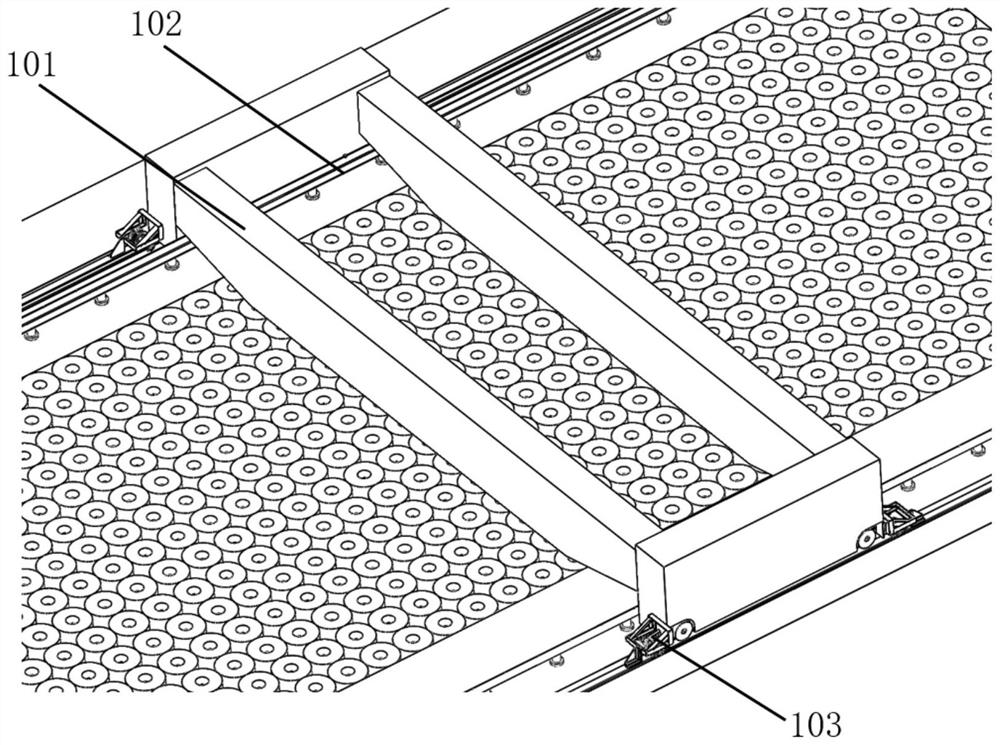

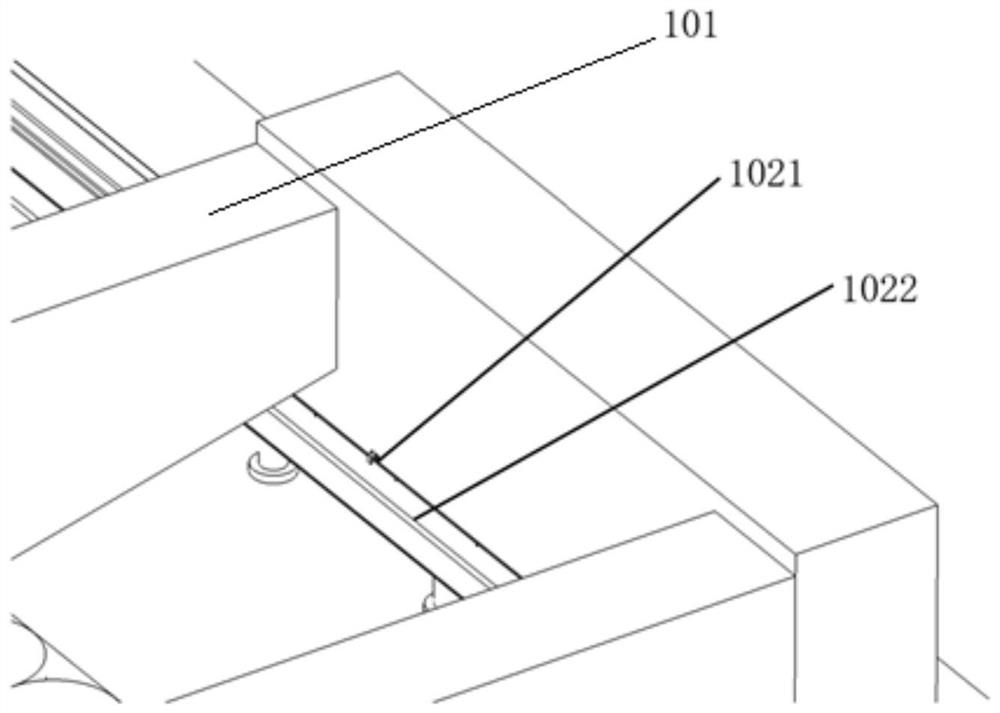

[0064] The quantitative multi-station automatic pouring machine in this embodiment includes a fixed-distance moving beam module 1, a large ladle dumping module 2 and a quantitative multi-station pouring module 3, and the large ladle dumping module 2 is fixed on the lateral direction of the fixed-distance moving beam module 1. On the beam, the quantitative multi-position pouring module 3 is connected between the two longitudinal beams of the fixed-distance moving beam module 1 through the rotating connection seat 3022, and can be rotated. refer to figure 2 , image 3 In the quantitative multi-station automatic pouring machine of this embodiment, the fixed-distance moving beam module 1 includes a beam 101, an equidistant positioning device 102, and the equidistant positioning device 102 includes a positioning sensor 1021 and a positioning sensor feedback mechanism 1022. The positioning sensor 1021 is installed on The longitudinal beam of the beam 101 is combined with the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com