Large-caliber rotary jetting drill pipe clamping device

A clamping device and large-diameter technology, applied in drill pipes, drill pipes, drilling equipment, etc., can solve the problems of inability to freely replace, wear slips, easy to loosen, etc., and achieve the effect of improving quality and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Regarding the aforementioned and other technical contents, features and effects of the present invention, refer to the appended figure 1 to attach Figure 4 It will be apparent from the detailed description of the embodiments. The structural contents mentioned in the following embodiments are all based on the accompanying drawings of the description.

[0023] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

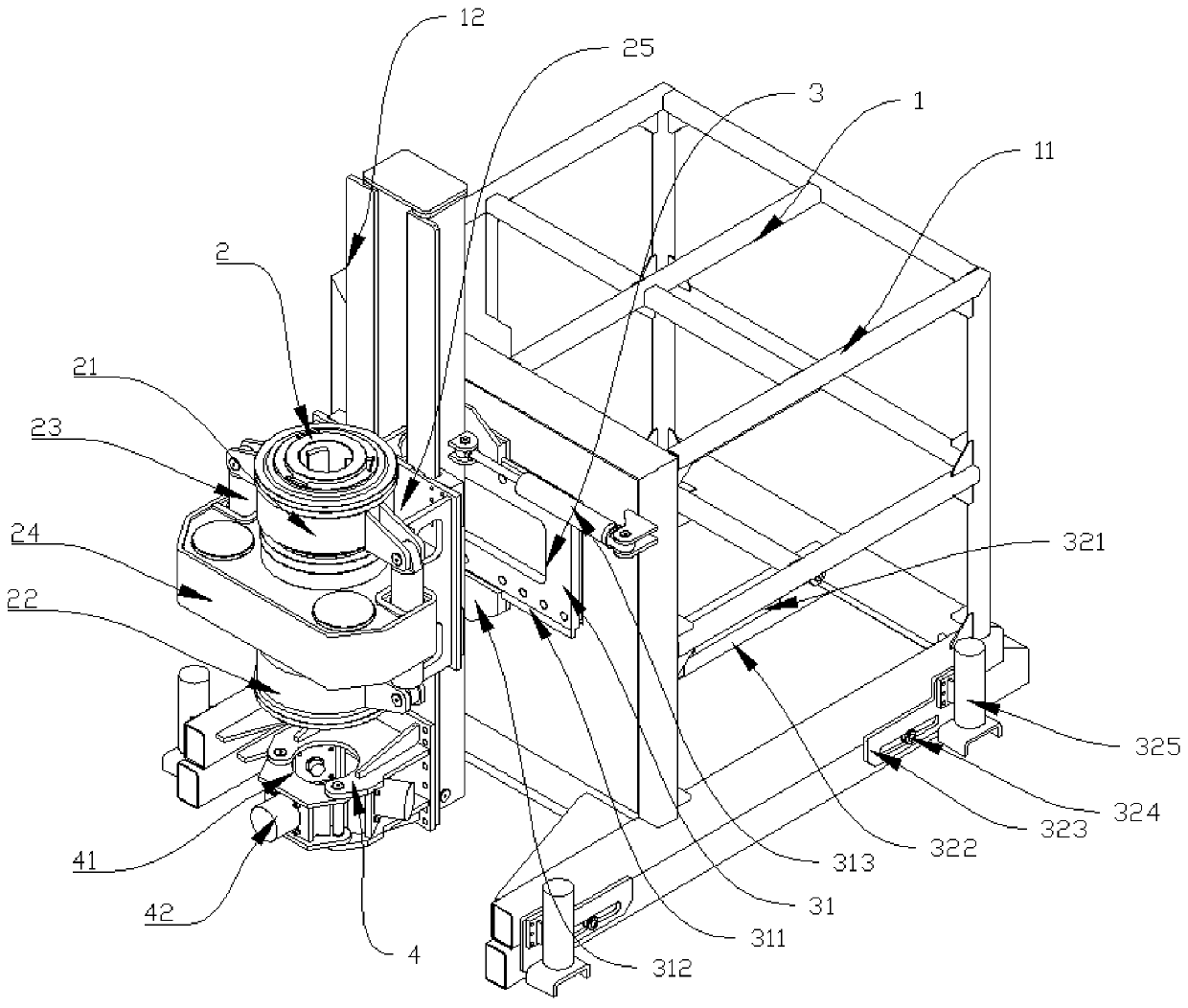

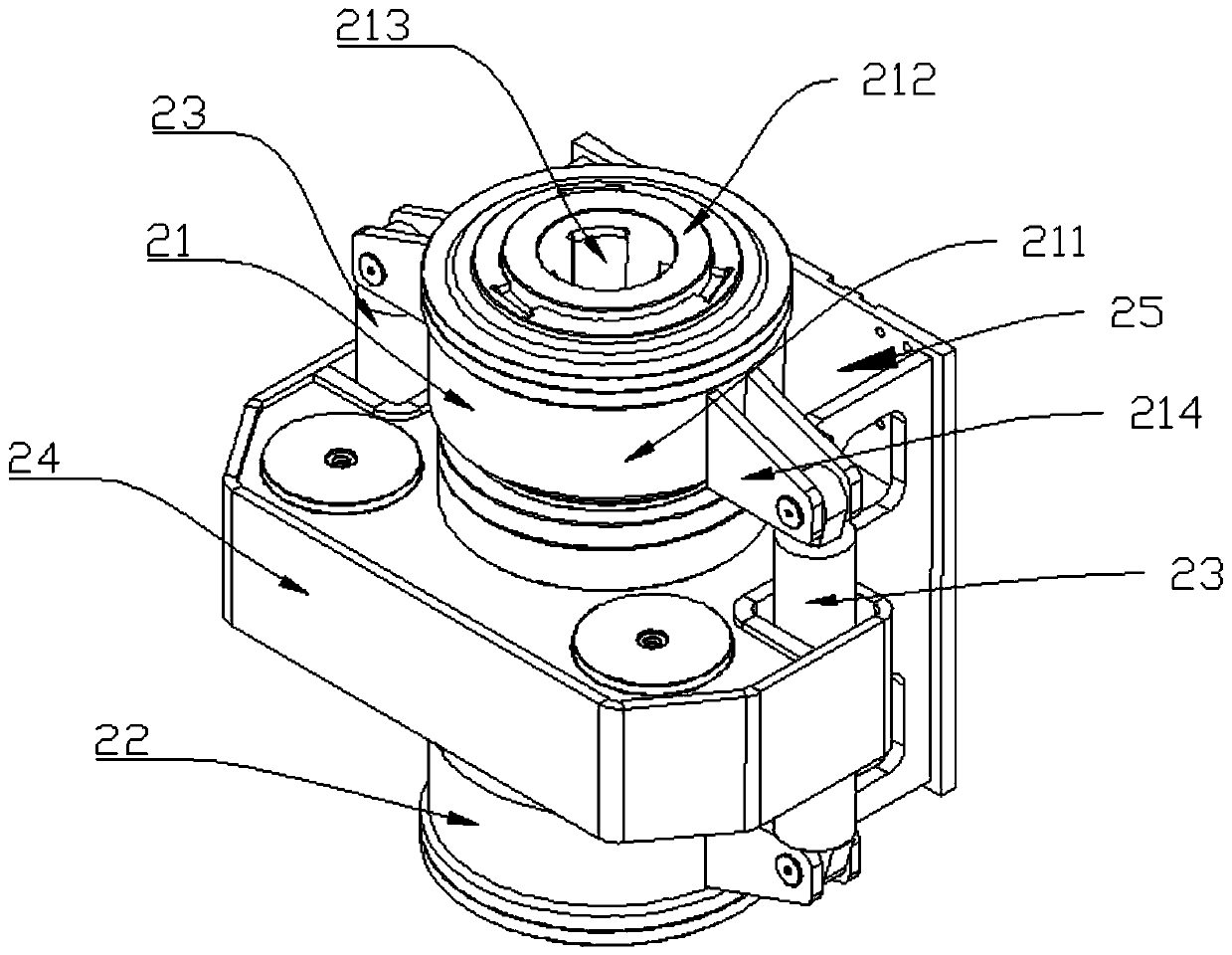

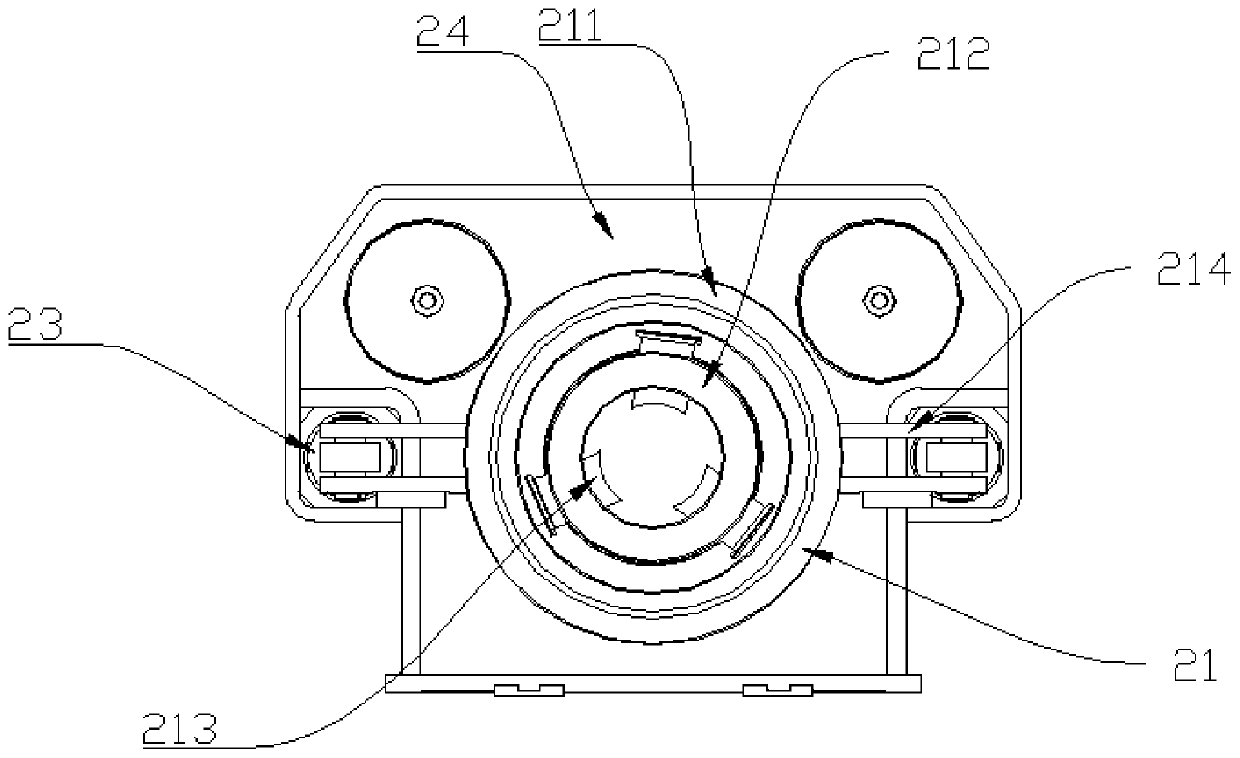

[0024] A clamping device for a large-diameter jet-jet drill pipe, which includes a support mechanism 1, a clamping mechanism 2, and an alignment mechanism 3. The support mechanism 1 includes a square support frame 11 and a support column 12 arranged in front of the support frame 11 , the alignment mechanism 3 includes an X-axis alignment mechanism 31 and a Y-axis alignment mechanism 32, the X-axis alignment mechanism 31 is arranged in front of the support frame 11, and a support column is fixed in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap