Method for one-time blasting shaft forming through deep hole sectional triangle net slotting

A triangular mesh and deep hole technology, applied in blasting and other directions, can solve problems such as high difficulty in excavation, high safety risks, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in more detail by the following examples, and the present invention is not limited to the following examples;

[0030] combined with Figure 1~4 The method for forming a well by blasting a deep-hole subdivision triangular network cutting at one time, specifically comprises the following steps:

[0031] The first step, digging the chamber:

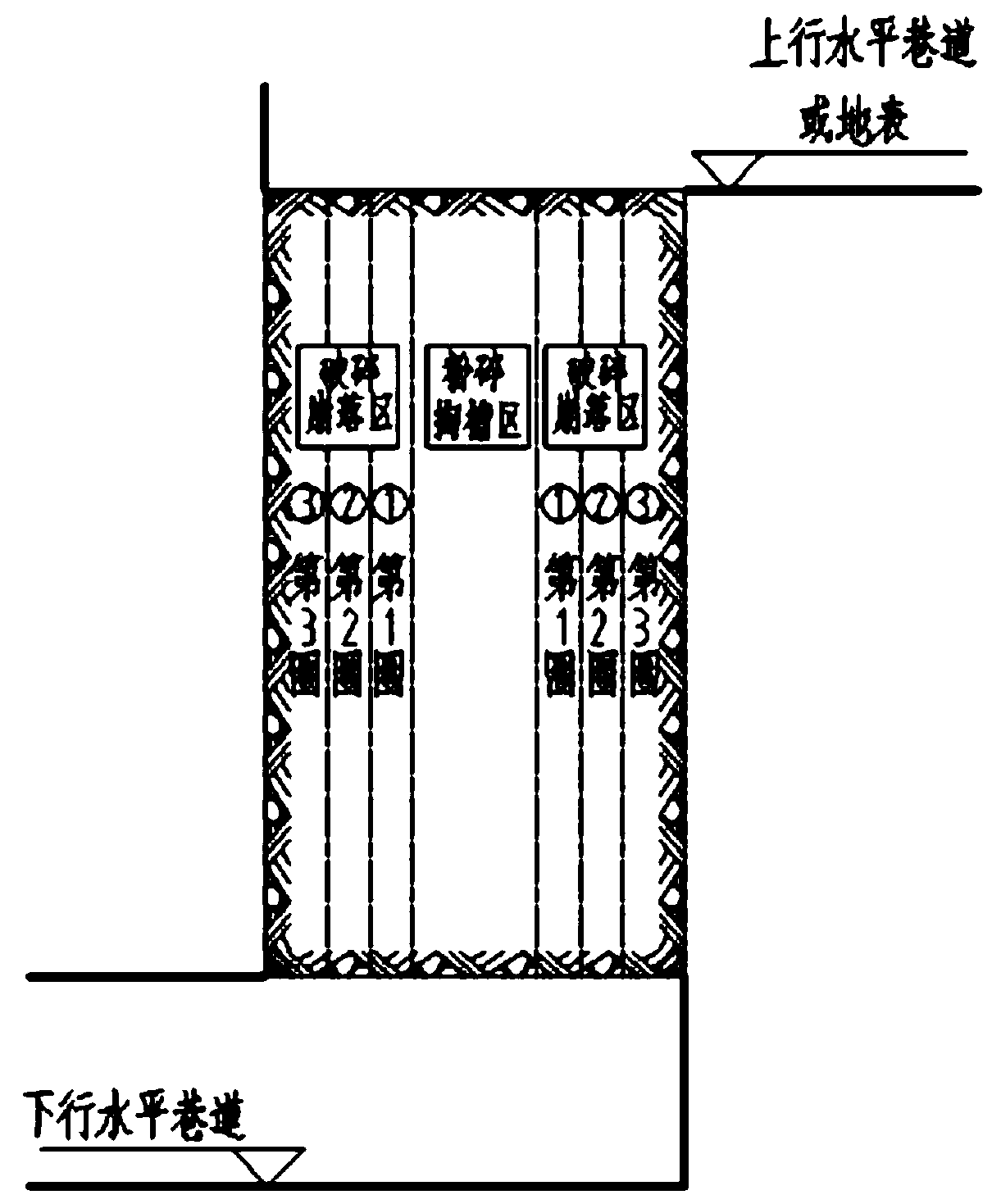

[0032] Such as figure 1 As shown, firstly excavate chambers at the bottom and top of the shaft to be excavated, and when the top of the shaft to be excavated extends to the surface, there is no need to excavate chambers at the top;

[0033] The second step is to arrange blastholes and drill holes:

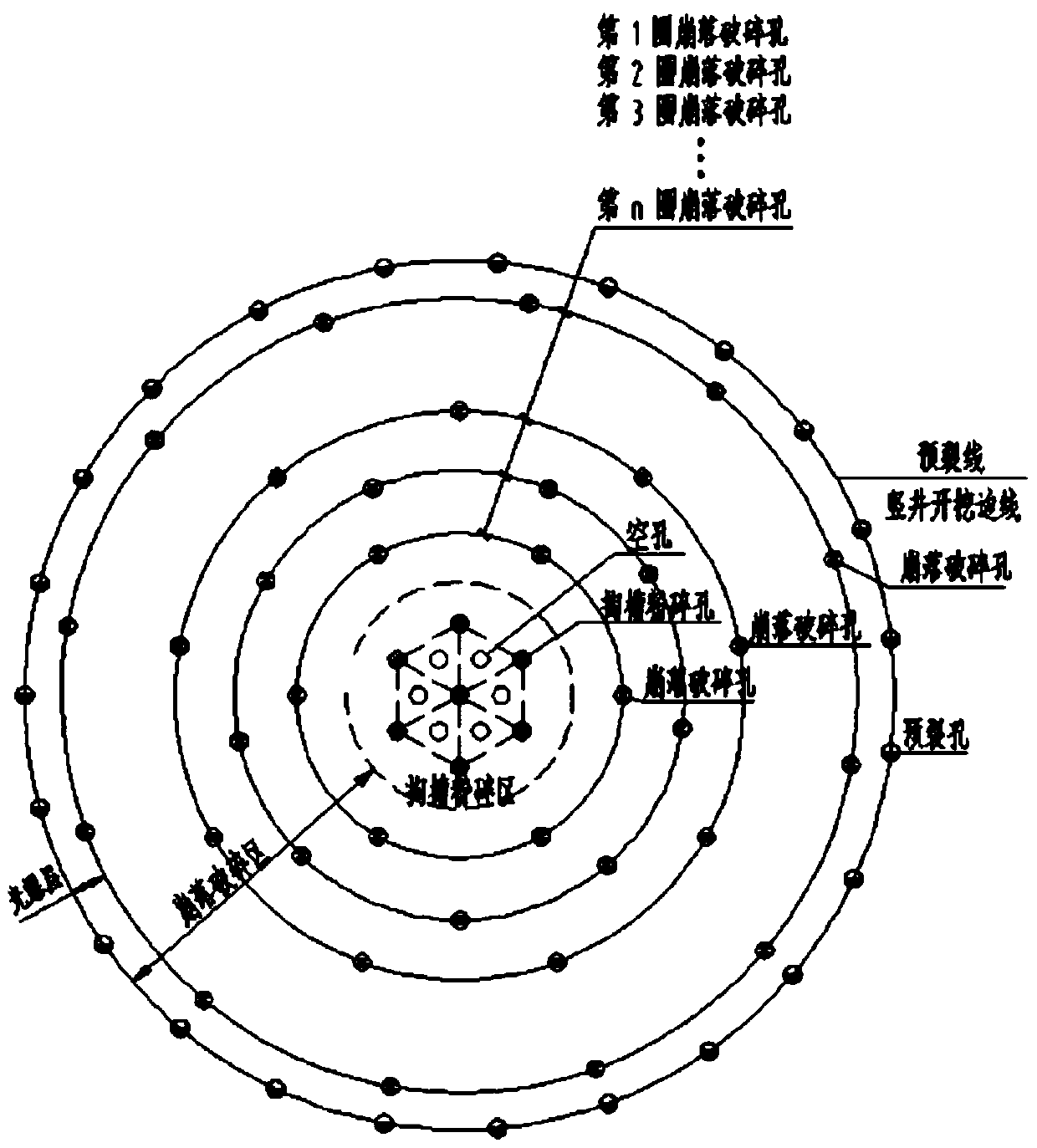

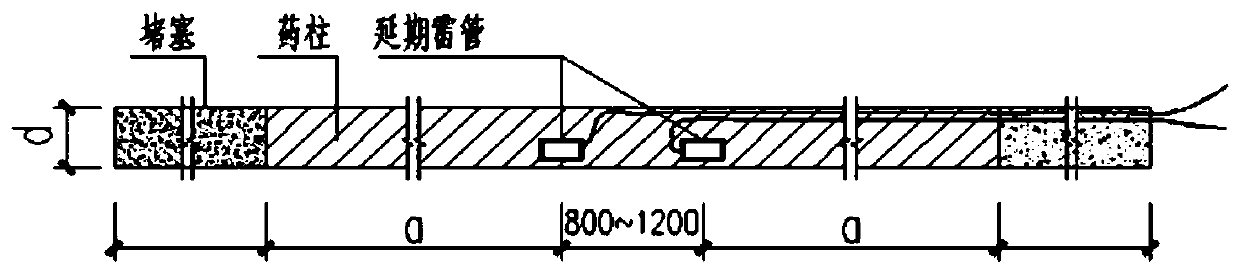

[0034] Continuing from the previous step, use a deep hole drilling rig to drill holes along the entire length of the shaft in the shaft. All the blast holes will be constructed at one time. Caving and crushing holes are arranged in the caving and crushing area between the edges, and pre-splitting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap