Capacity detection device for air flow velocities and detection method thereof

A technology of capacity detection and air flow rate, used in measuring devices, fluid velocity measurement, liquid/fluid solid measurement, etc., can solve problems such as inability to detect, and achieve the effect of improving accuracy, product quality, and production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

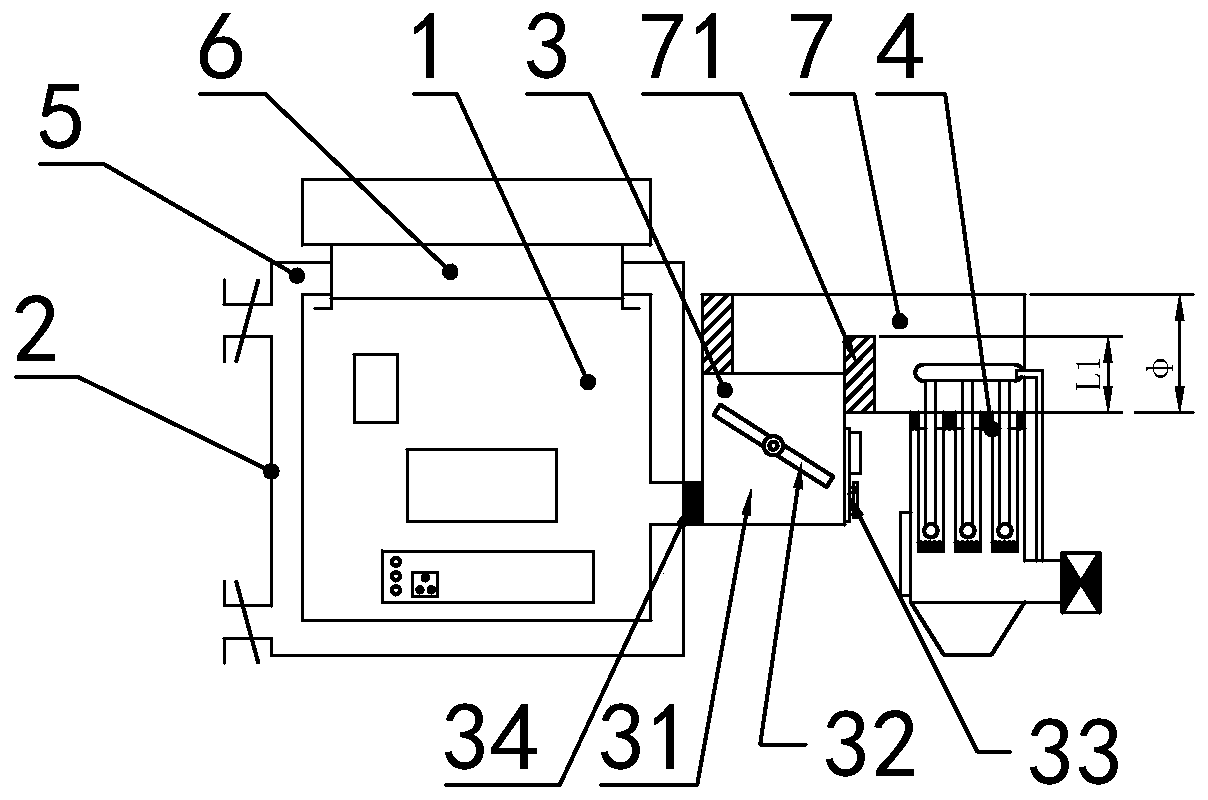

[0036] Such as Figure 1-Figure 5 As shown, the present invention discloses a capacity detection device for air flow velocity. In a specific embodiment of the present invention, it includes a flow velocity detection box 1, an air leakage detection box 2, a flow limiting device 3 and a large particle filter for filtering air. The filter device 4; the flow rate detection box 1 is arranged in the inner cavity of the air leakage detection box 2 and an air storage chamber 5 is formed between the two, the air inlet of the flow rate detection box 1 communicates with the air outlet of the flow limiting device 3, and the flow rate The air outlet of the detection box 1 passes through the side wall of the air leakage detection box 2 and extends outward to form a detection port 6 ;

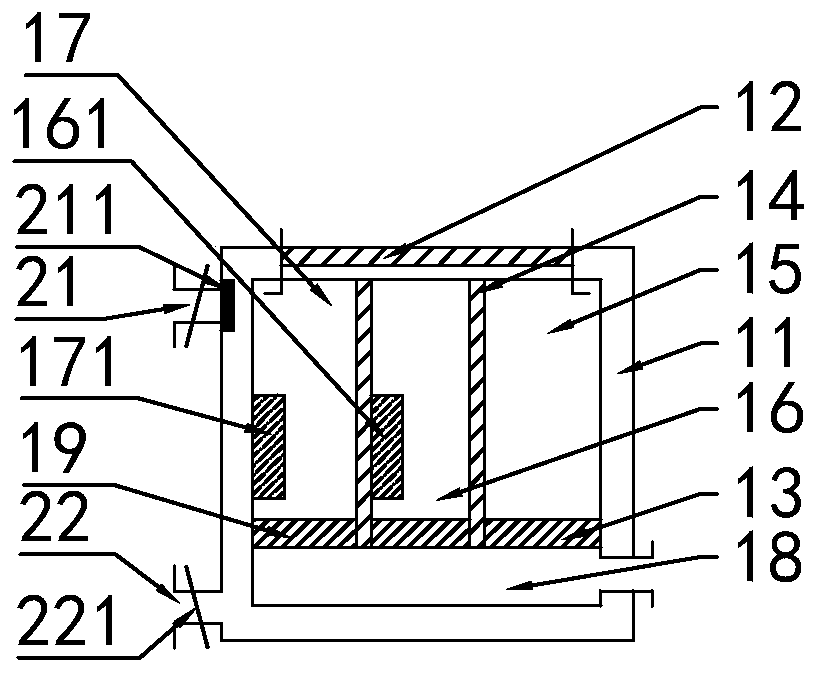

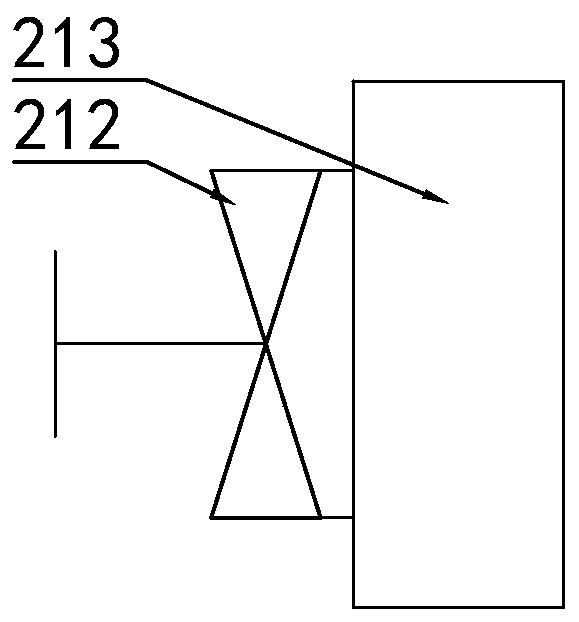

[0037] In a specific embodiment of the present invention, the flow rate detection box 1 includes a box body 11 and a flow rate flowmeter 12; the flow rate flowmeter 12 is installed on the air outlet of the bo...

Embodiment 2

[0053] In addition, the present invention also discloses a capacity detection method of air flow rate, comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com