Wavelength conversion device, preparation method thereof, light source device and projection equipment

A technology of wavelength conversion device and light source device, which is applied in the field of projection display, can solve problems such as yellow apertures and different proportions, and achieve the effects of reducing optical path difference, facilitating molding, and improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

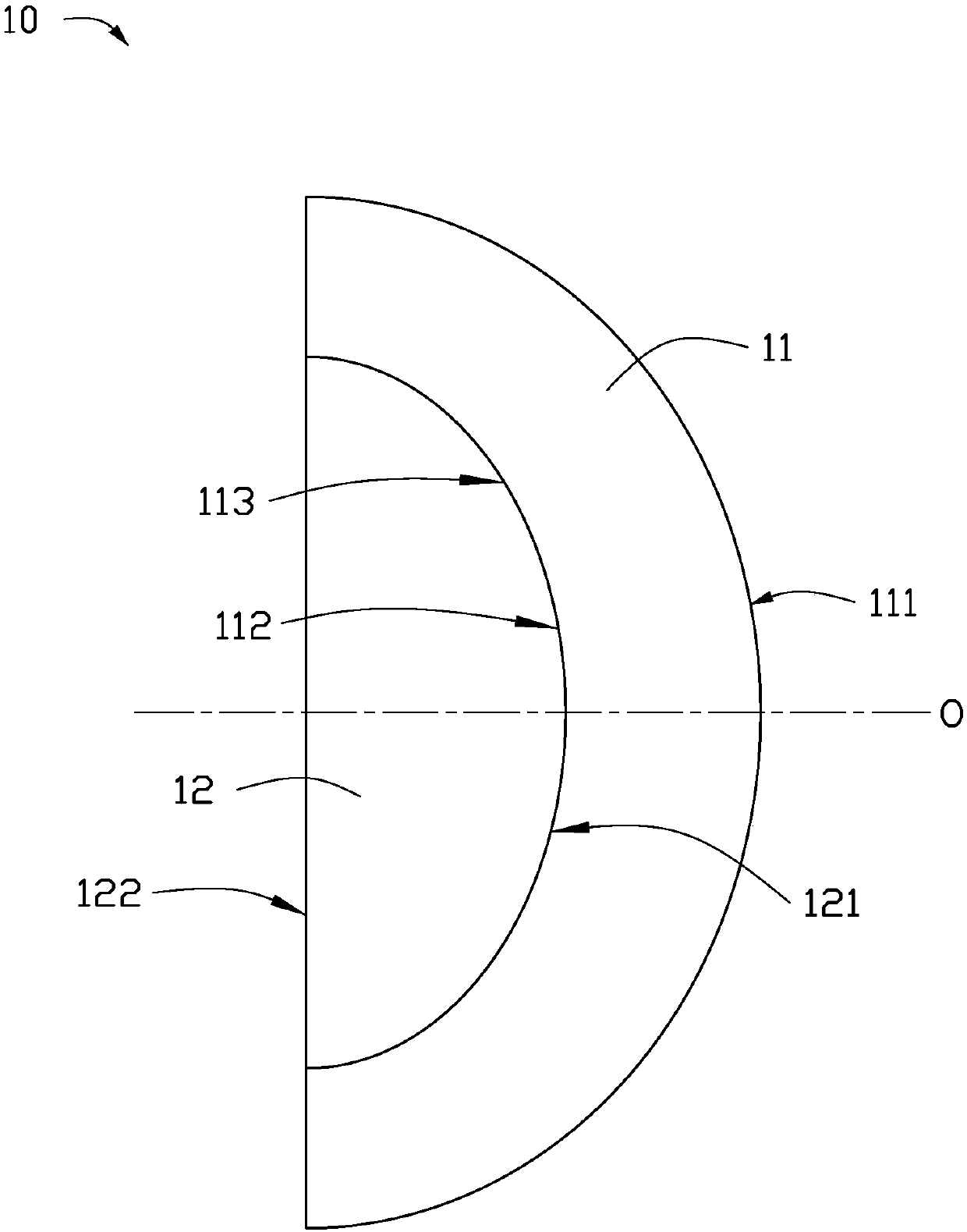

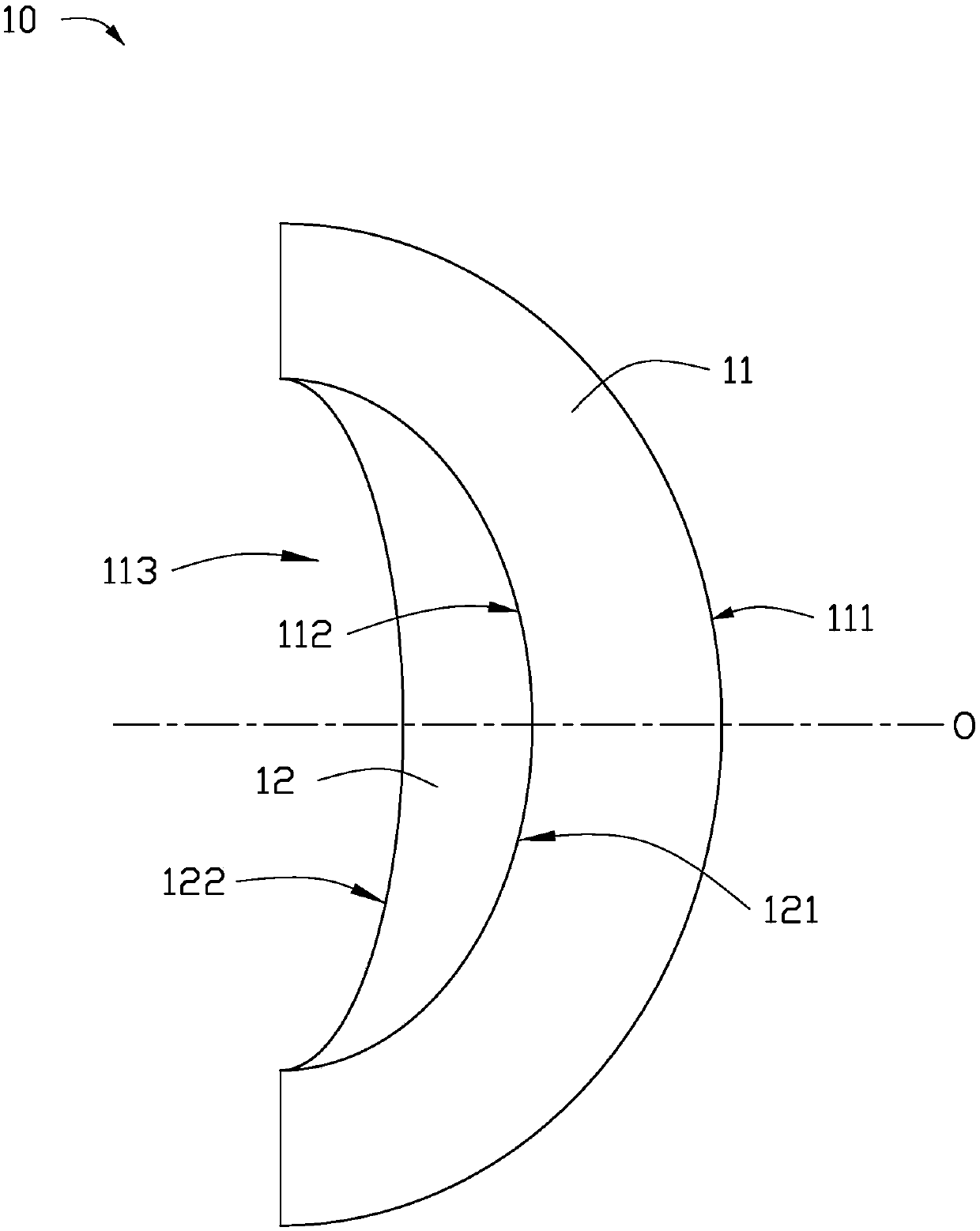

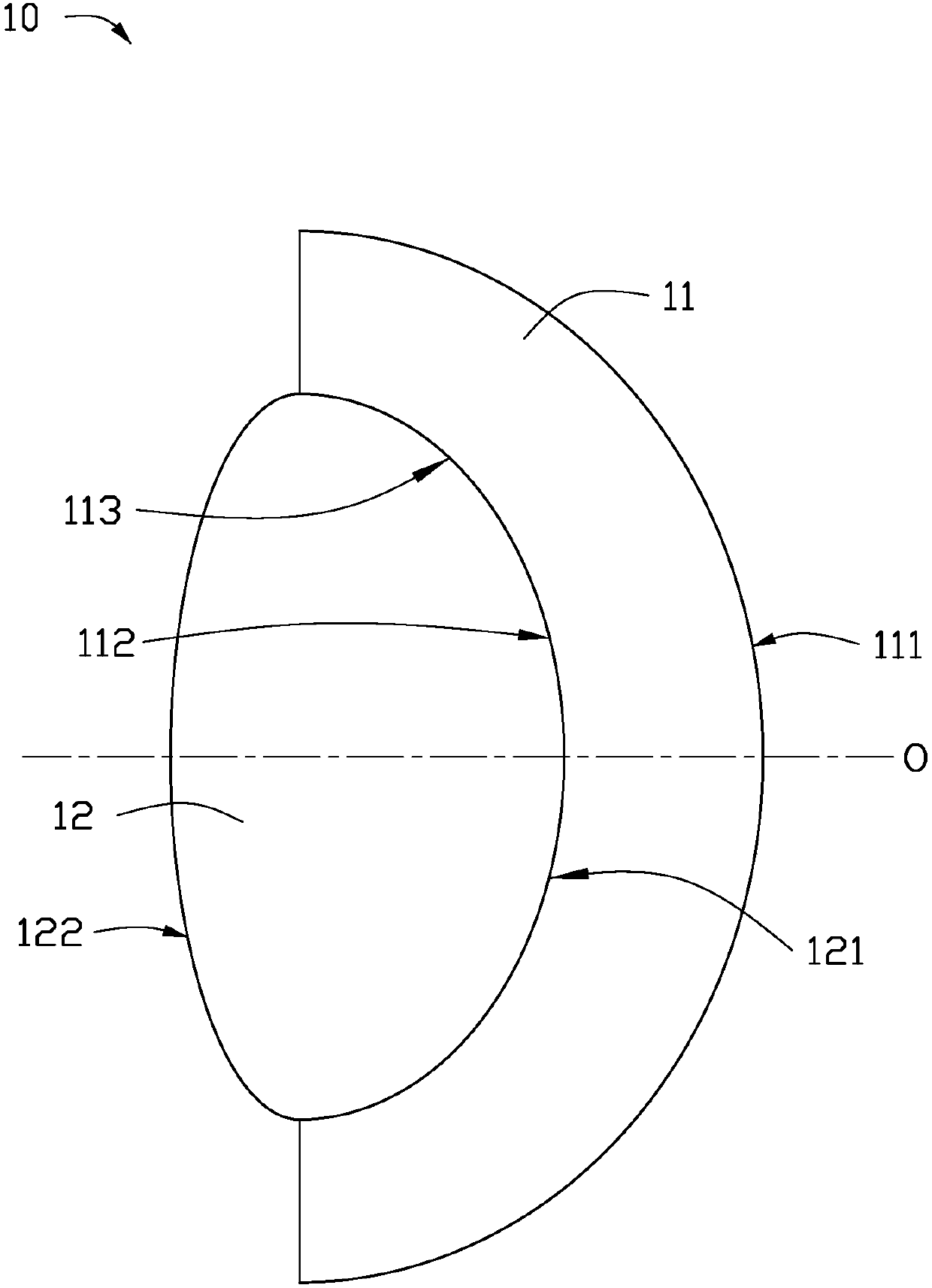

[0046] see Figure 1-3 , Figure 1-3 They are schematic structural diagrams of wavelength conversion devices 10 with different structures according to the first embodiment of the present invention. The wavelength conversion device 10 includes a meniscus lens unit 11 and a wavelength conversion unit 12 , and the meniscus lens unit 11 can serve as a support for the wavelength conversion unit 12 , functioning as a mold and a support.

[0047] The meniscus lens unit 11 includes a convex surface 111 and a concave surface 112 on the opposite side of the convex surface 111, the curvature radii of the convex surface 111 and the concave surface 112 may be the same or different, for example, the convex surface 111 And the concave surface 112 can be a spherical surface with the same or different radii, the concave surface 112 is formed with a groove 113, and one side of the wavelength conversion unit 12 is bonded to the groove 113, so that the wavelength conversion There is no air gap ...

no. 2 example

[0056] see Figure 5-7 , Figure 5-7 They are schematic structural diagrams of wavelength conversion devices 20 with different structures according to the second embodiment of the present invention. The main difference between this embodiment and the first embodiment is that this embodiment also includes a reflective layer 13, and the wavelength conversion device 20 provided in this embodiment is a reflective structure. It should be understood that each specific embodiment in the first embodiment The implementation manners can be correspondingly applied to this embodiment.

[0057] Such as Figure 5-7 As shown, a reflective layer 13 is provided on the second surface 122 of the wavelength conversion unit 12. The reflective layer 13 can cover the surface of the concave-convex lens unit 11 on the same side as the second surface 122. The reflective layer 13 can use Silicone or glass encapsulated Al 2 o 3 、TiO 2 Other white granular material. The laser light source is incide...

no. 3 example

[0061] Such as Figure 9 as shown, Figure 9 A flowchart of a method for preparing a wavelength conversion device provided by an embodiment of the present invention. The preparation of the wavelength conversion device provided by this embodiment may include the following steps:

[0062] S11: providing a meniscus lens unit.

[0063] Wherein, the meniscus lens unit 11 is used as a support body, the meniscus lens unit 11 may include a convex surface 111 and a concave surface 112 on the opposite side of the convex surface 111, the curvature of the convex surface 111 and the concave surface 112 The radii can be the same or different. The concave surface 112 is formed with a groove 113, and the groove 113 serves as a mold cavity.

[0064] The concave-convex lens unit 11 can be made of high thermal conductivity material, the thermal conductivity is preferably greater than 5W / m·K, more preferably greater than or equal to 10W / m·K, which can improve the thermal conductivity of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com