Display panel, manufacturing method thereof and display device

A technology for display panels and display devices, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., and can solve the problems of different optical paths and excessively large viewing angle of display panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

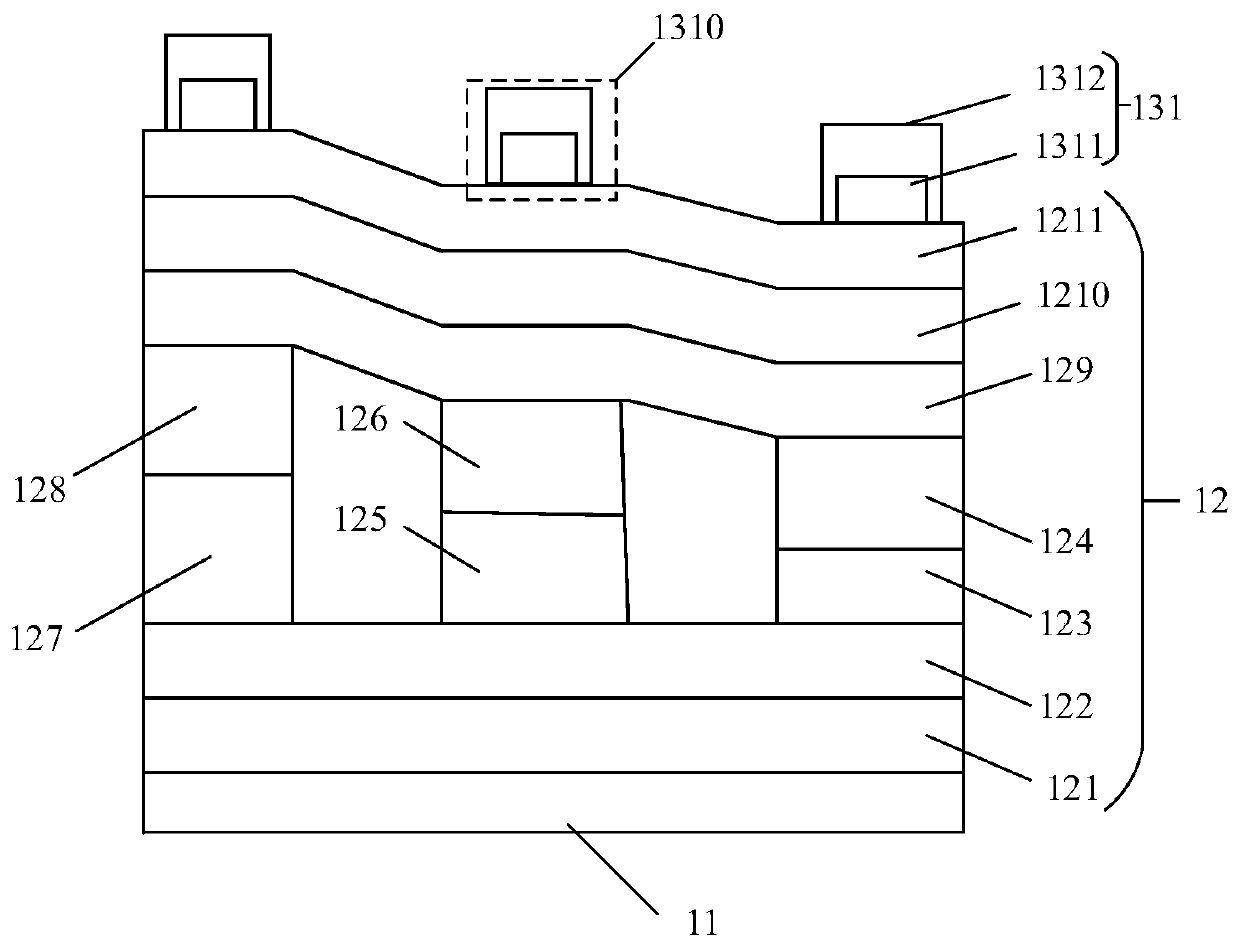

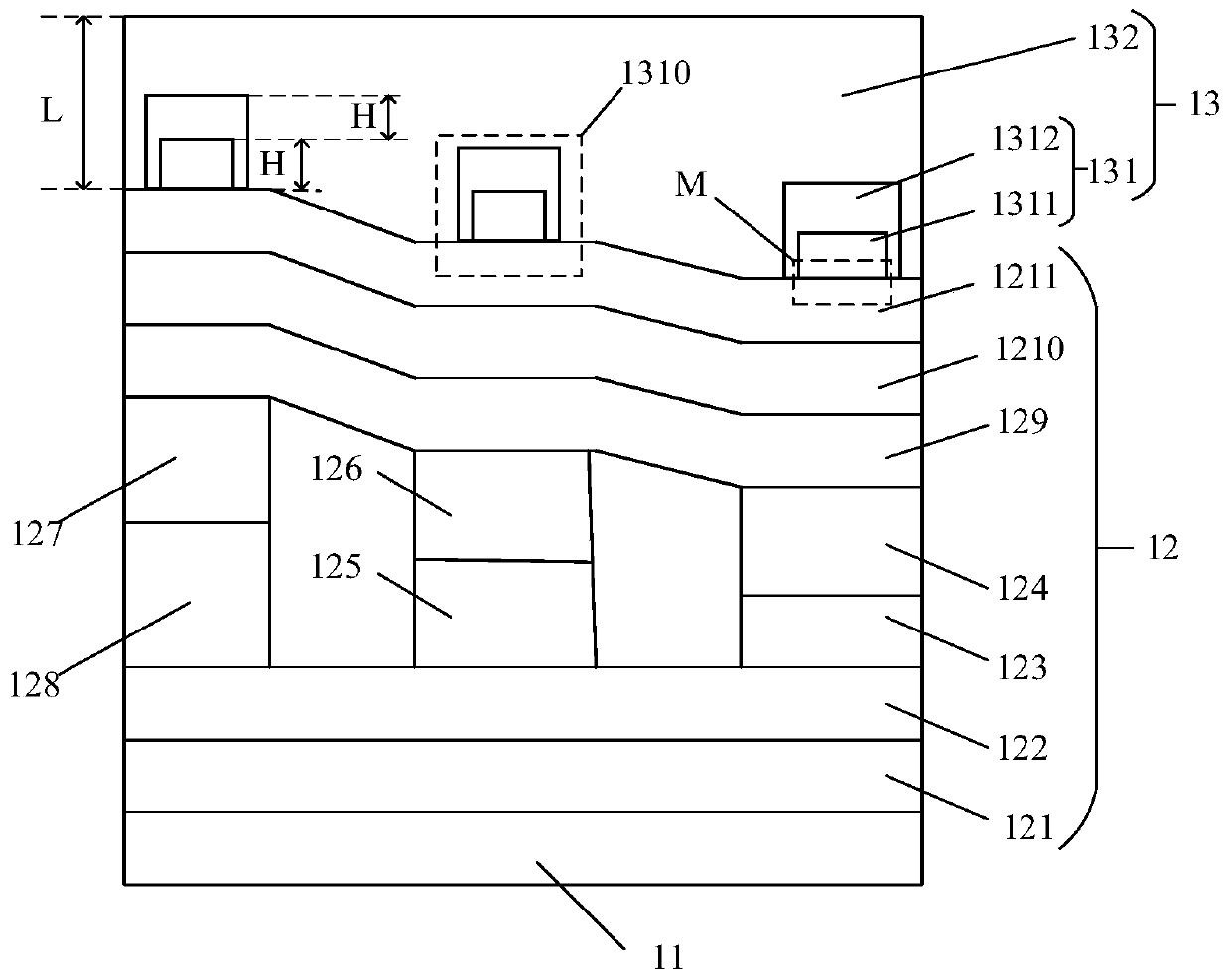

[0038] refer to figure 1 , showing a schematic structural diagram of a display panel according to an embodiment of the present invention, figure 2 A schematic structural diagram of another display panel according to an embodiment of the present invention is shown.

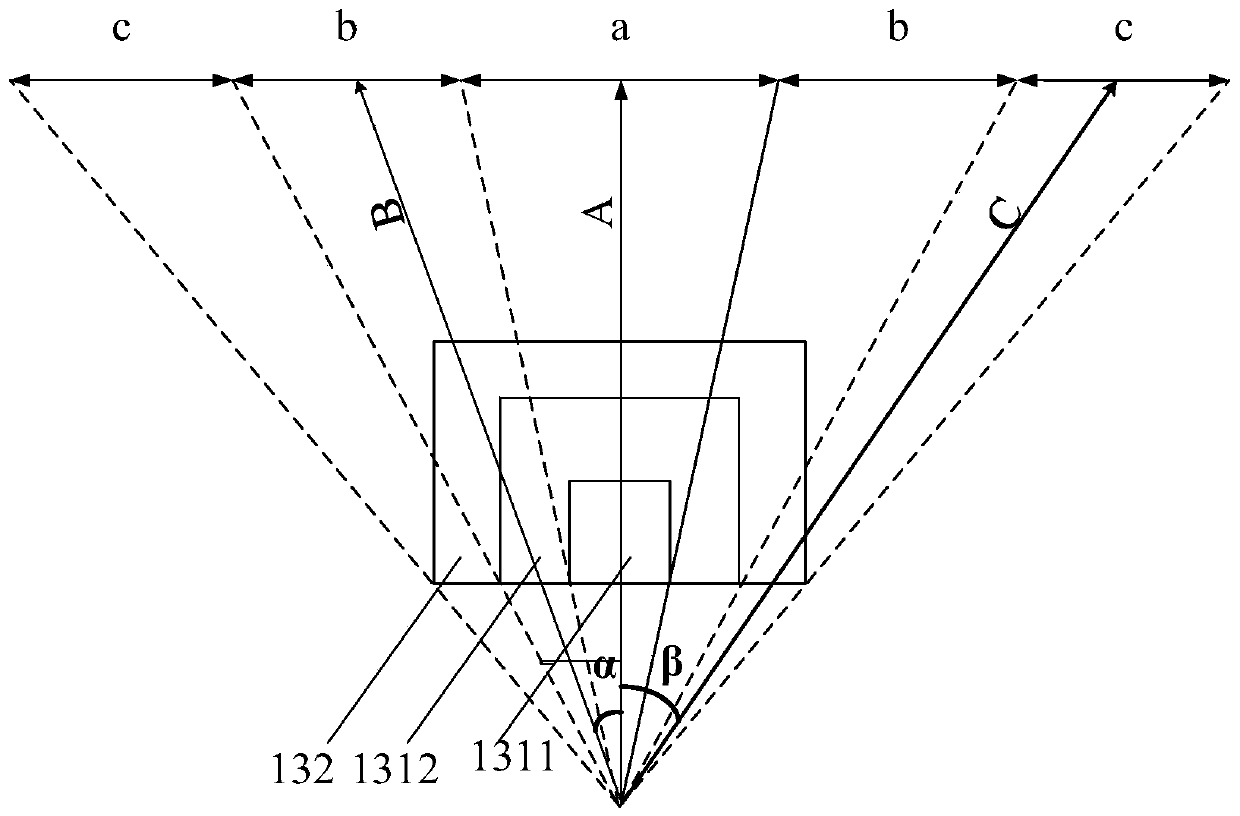

[0039] An embodiment of the present invention provides a display panel, which includes a base substrate 11, a plurality of organic light emitting devices 12 disposed on the base substrate 11, and at least two layers of optical coupling layers 13 disposed on the organic light emitting devices 12 , for any two adjacent optical coupling layers 13, the optical coupling layer 13 far away from the base substrate 11 covers the optical coupling layer 13 close to the base substrate 11, and the refractive index of the optical coupling layer 13 far away from the base substrate 11 is less than The refractive index of the light coupling layer 13 close to the base substrate 11 .

[0040] It should be noted, figure 1 and fi...

Embodiment 2

[0066] refer to Figure 5 , which shows a flow chart of a method for manufacturing a display panel according to an embodiment of the present invention, which may specifically include the following steps:

[0067] Step 501, providing a base substrate.

[0068] Step 502, forming a plurality of organic light emitting devices on the base substrate.

[0069]In the embodiment of the present invention, a plurality of organic light-emitting devices 12 are formed on the base substrate 11. The base substrate 11 may be a glass substrate or a PI (Polyimide, polyimide) substrate. The organic light-emitting devices 12 include The anode 121 on the anode 121, and the hole transport layer 122 arranged on the anode 121, the electron blocking layer arranged on the hole transport layer 122, the color light-emitting layer arranged on the electron block layer, the spacer arranged on the color light-emitting layer A hole blocking layer 129 , an electron transport layer 1210 disposed on the hole bl...

Embodiment 3

[0089] The embodiment of the present invention also discloses a display device, including the above-mentioned display panel. The display panel includes a base substrate 11, a plurality of organic light-emitting devices 12 arranged on the base substrate 11, and a plurality of organic light-emitting devices arranged on the organic light-emitting devices 12. At least two layers of optical coupling layers 13, for any adjacent two layers of optical coupling layers 13, the optical coupling layer 13 away from the base substrate 11 covers the optical coupling layer 13 close to the base substrate 11, and the optical coupling layer 13 away from the base substrate 11 The refractive index of the coupling layer 13 is smaller than that of the optical coupling layer 13 close to the base substrate 11 .

[0090] In this embodiment of the present invention, for a specific description of the display panel, reference may be made to the description of Embodiment 1, which will not be repeated in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com