Electrical switch and conductive connecting structure thereof

A conductive connection structure and electrical switch technology, applied in the direction of conductive connection, electrical component connection, connection, etc., can solve problems such as difficult to clean and difficult to find metal debris, and achieve the effects of ensuring insulation performance, easy cleaning, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

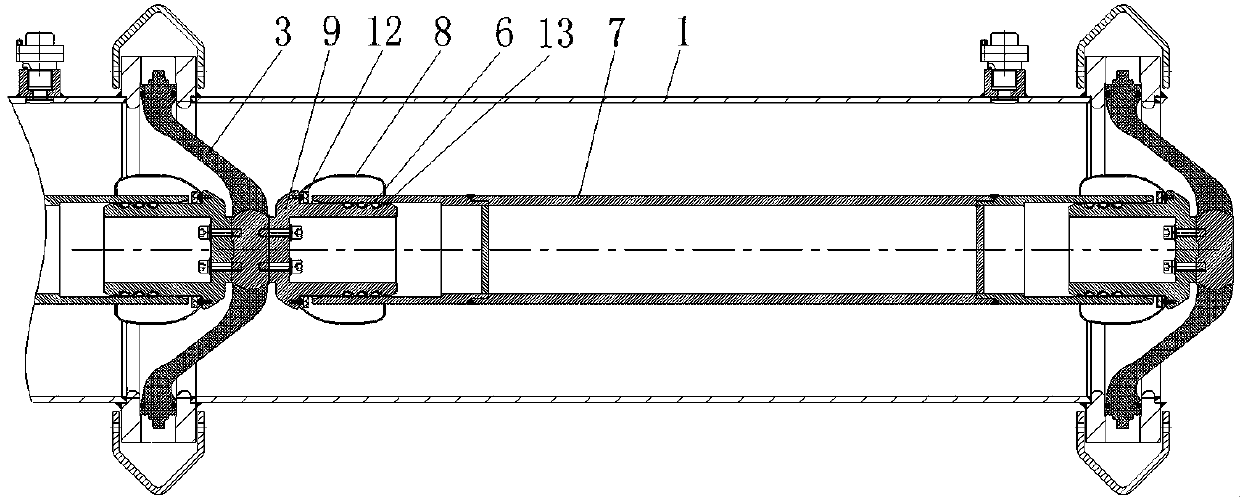

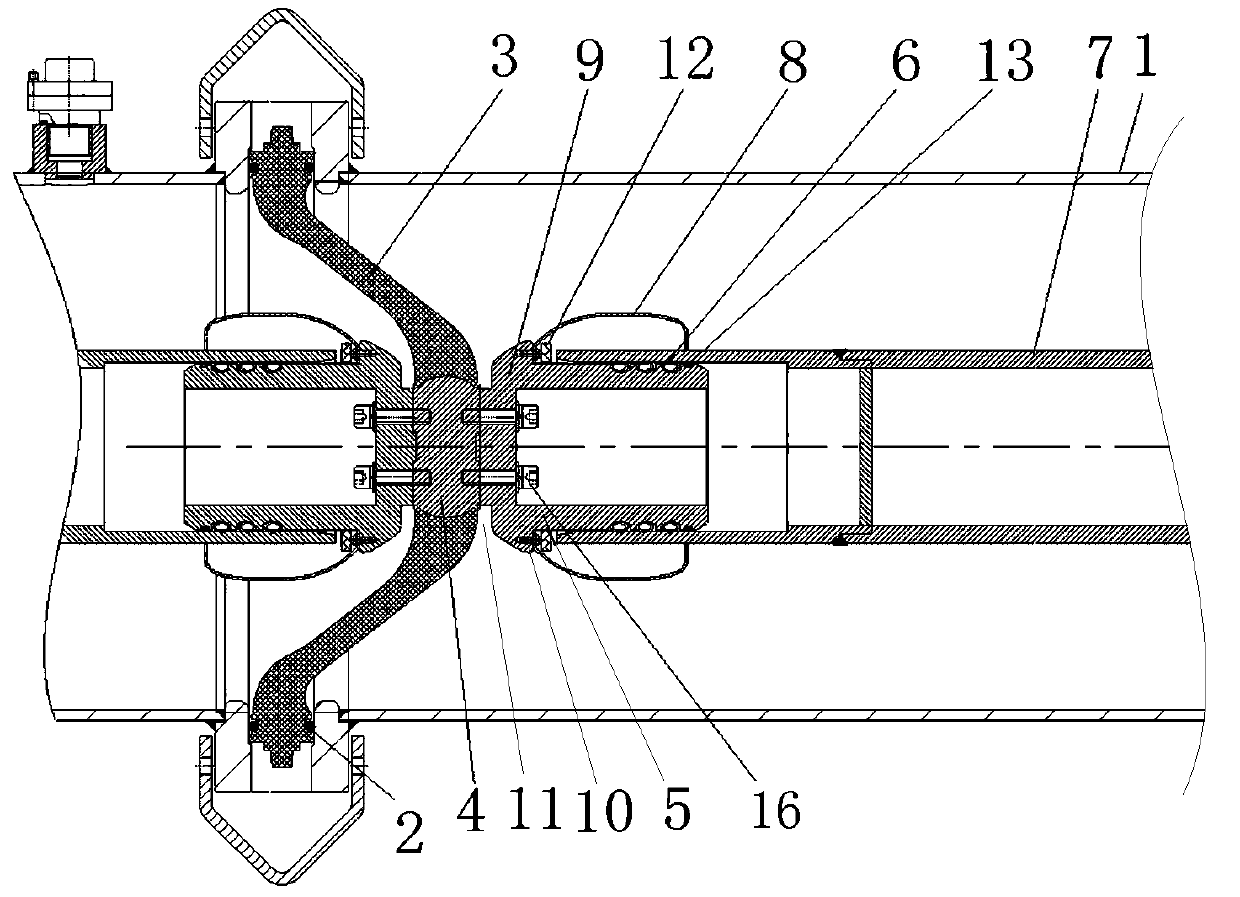

[0049] Such as figure 1 with figure 2 As shown, the conductive connection structure for an electrical switch includes two insulated cylinders 1, the opposite ends of the two cylinders 1 are fixedly assembled together, and a basin insulator 3 is sandwiched between the opposite ends of the two cylinders. 3 and the end faces of the opposite ends of the two cylinders are provided with a sealing ring 2 to realize the sealing assembly between the basin-type insulator 3 and the corresponding cylinders. Generally, an annular groove is provided on the corresponding surface of the basin insulator 3, and the sealing ring 2 can be fixed in the corresponding annular groove.

[0050] A conductive element 4 is embedded in the middle of the basin bottom of the basin insulator 3. In this embodiment, the two ends of the conductive element 4 corresponding to the two cylinders 1 are respectively fixedly provided with electrical connection contact seats 5, and the two electrical connection contacts ...

Embodiment 2

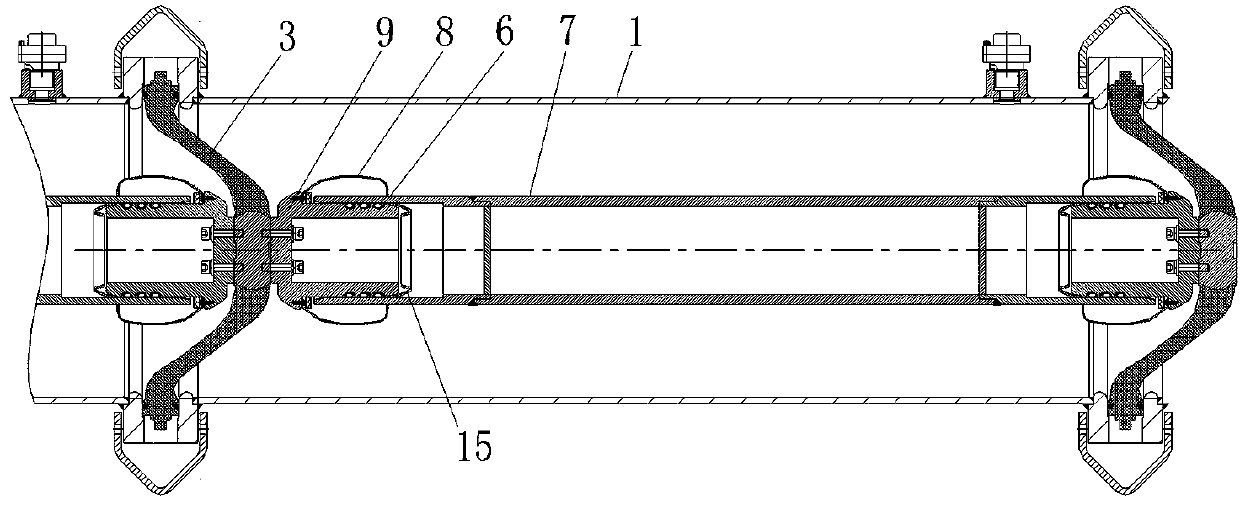

[0065] Its structure is like image 3 with Figure 4 As shown, and basically the same as the conductive connection structure in Embodiment 1, the difference is mainly: In Embodiment 1, the outer peripheral surface of the electrical connection contact seat 5 is provided with a guide ring 13 that guides the conductive tube 7, and In the second embodiment, no guide ring is provided on the outer peripheral surface of the electrical connection contact base 14, and the front end surface of the electrical connection contact base 14 is provided with a guiding plastic piece 15 that is sleeved on the outer chamfer of the front end surface. Under the action, the guiding assembly of the conductive tube 7 and the electrical connection contact base 14 can be realized.

Embodiment 3

[0067] The difference from embodiment 1 is that: in embodiment 1, the annular boss is arranged at the rear of the electrical connection contact base 5. The front side of the annular boss forms the shielding cover mounting surface, and the circumferential side wall of the annular boss and its rear The side arc transition connection, and in embodiment 3, the annular boss is arranged in the middle of the electrical connection contact seat, the front side of the annular boss forms the shielding cover mounting surface, and the circumferential side walls of the annular boss extend directly in the front and rear directions To the back end of the electrical connection contact seat, that is, the back end of the ring boss is the back end of the electrical connection contact seat. The back end of the ring boss is directly in contact with the front end of the conductive element, and the back end of the ring boss There is no cleaning interval with the basin insulator, which can reduce the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com