Casting nozzle

A nozzle and casting machine technology, applied in the field of casting nozzles, can solve the problems of casting material quality, molten metal cannot be uniformly input, etc., and achieve the effect of cheap manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

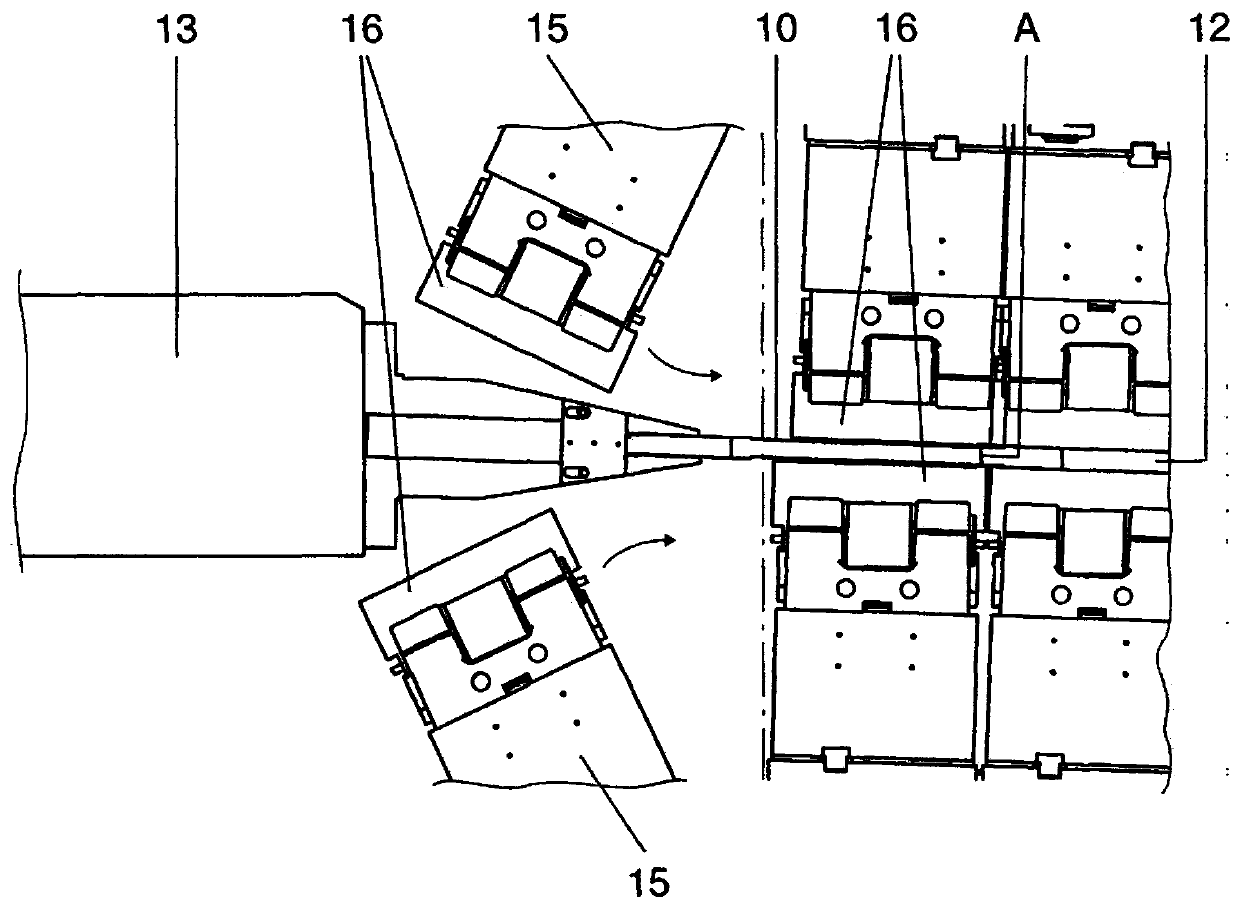

[0025] Refer below Figures 1 to 9 A preferred embodiment of a casting nozzle 10 according to the invention is described for injecting molten metal 11 , in particular non-ferrous metals such as aluminum or aluminum alloys, into a moving mold 12 of a crawler casting machine 14 . In the figures, identical features are provided with the same reference numerals. It should be pointed out here in particular that the drawings are only shown simplified and in particular not to scale.

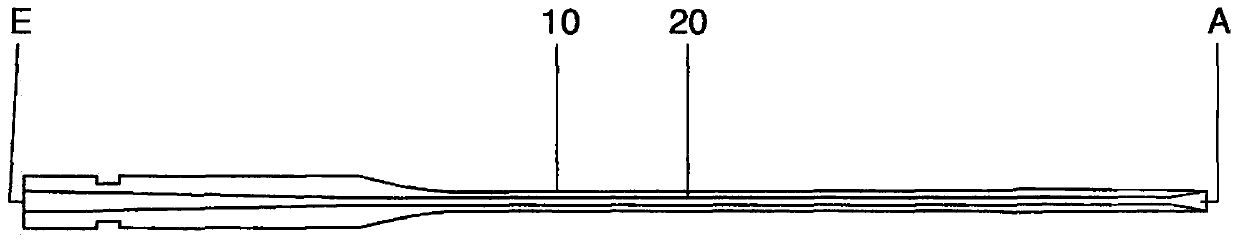

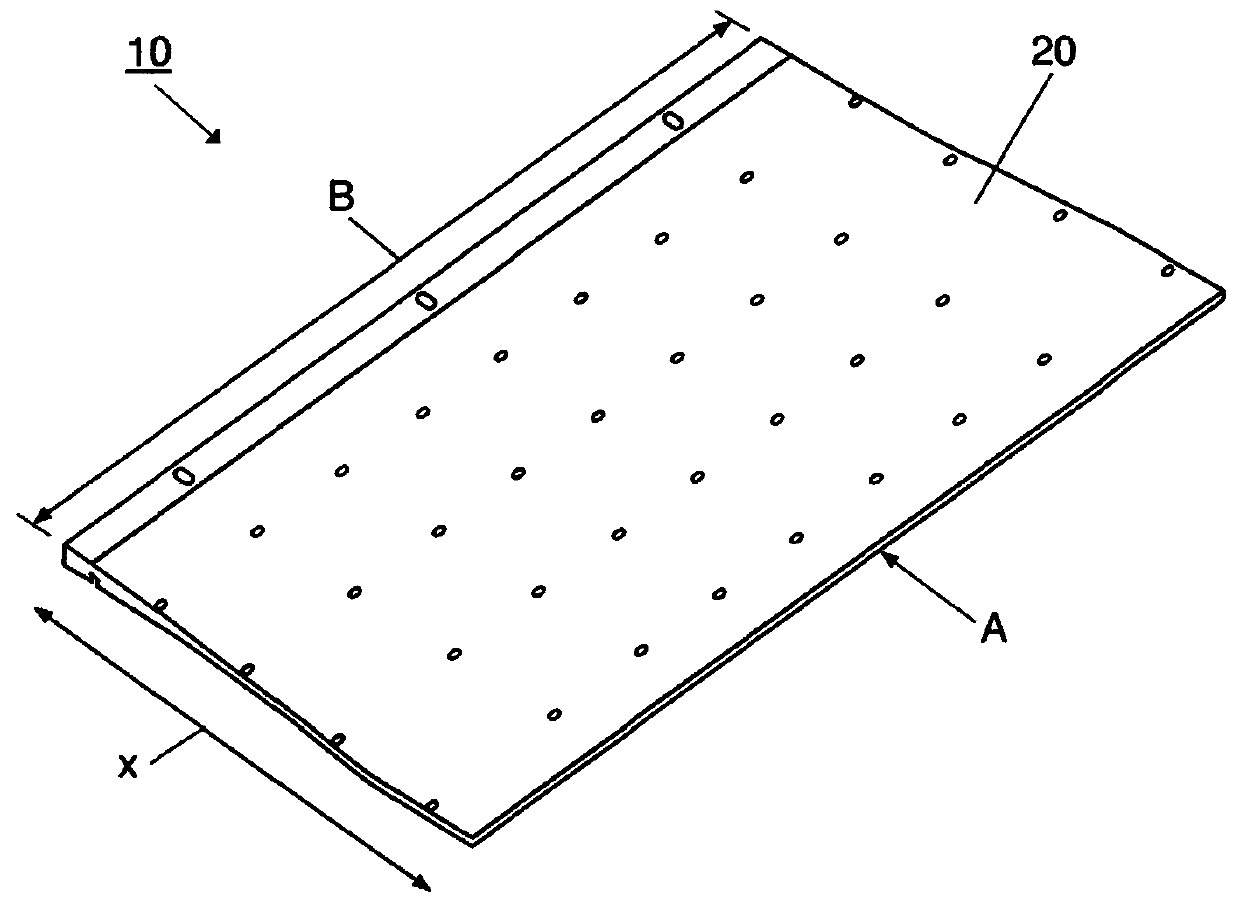

[0026] figure 1 A side view of a casting nozzle 10 according to the invention is shown, having a housing 20 with an inlet side E and an outlet side A. FIG. Housing 20 is at its height (at figure 1 in the vertical direction) is constructed in two parts and here comprises at least one upper casing 24 and at least one lower casing 26, which are separated from each other by spacers 28 (see for example Figure 6 ). Between these webs 28 the individual flow channels extend from the inlet side E to the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com