Short Inorganic Trisilylaminopolysilazanes for Thin Film Deposition

A technology of dialkylamino and atomic layer deposition, applied in organic chemistry, compounds of group 4/14 elements of the periodic table, coatings, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0231] The following examples illustrate experiments performed in conjunction with the disclosure herein. This example is not intended to be all-inclusive and is not intended to limit the scope of the disclosures described herein.

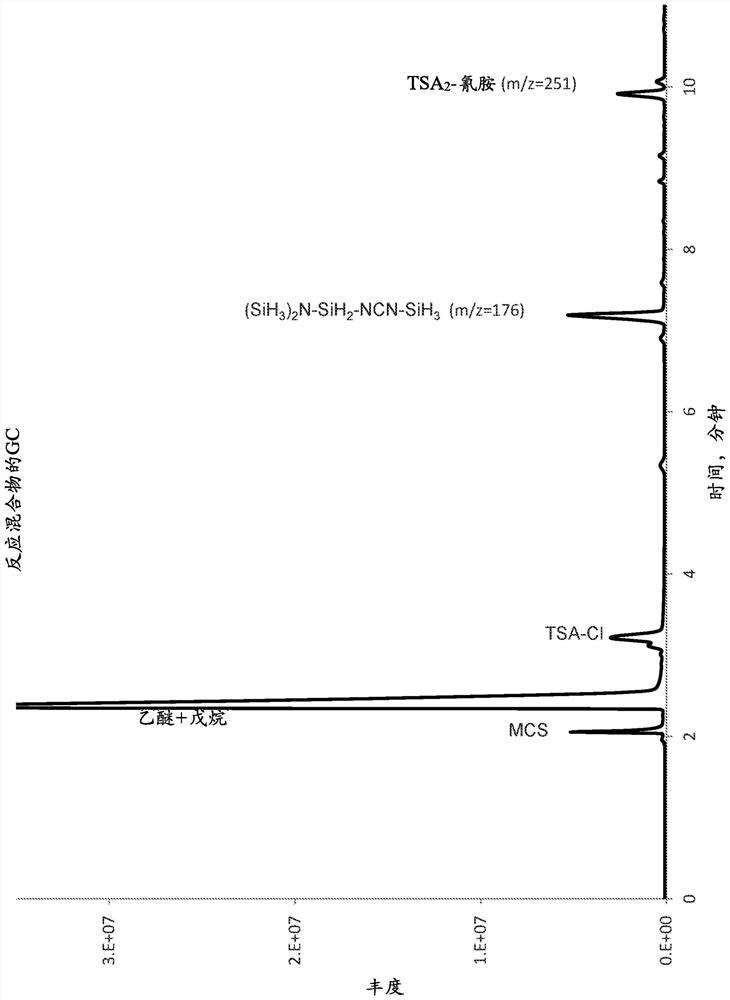

[0232] In the glove box, 0.35g (2.7mmol) of (H 3 Si) 2 -N-SiH 2 Cl(TSA-Cl)* was mixed with 0.39 g of pentane. This mixture was added to 0.1 g (2.4 mmol) cyanamide (H 2 N-CN). A white precipitate appeared immediately. The solution was filtered twice. Both times the initially clear filtrate became cloudy.

[0233] The inferred reaction is 2(SiH 3 ) 2 NSiH 2 -Cl+4H 2 N-CN→[(SiH 3 ) 2 NSiH 2 ] 2 -NCN+2H 2 N-CN*HCl

[0234] Gas chromatography (GC) analysis indicated the presence of monochlorosilane, diethyl ether and pentane, unreacted TSA-Cl, (SiH 3 ) 2 NSiH 2- N-C≡N-SiH 3 , or [(SiH 3 ) 2 NSiH 2 ] 2 -N-C≡N(TSA 2 - cyanamide). There are many other smaller, unidentified peaks. The GC spectrum of the mixture is shown in figur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap