Composite spherical hinge

A compound ball and hinge technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems that cannot be guaranteed to overlap at a fixed point, cannot be guaranteed to be independent of each other, and achieve the effect of convenient processing and manufacturing and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

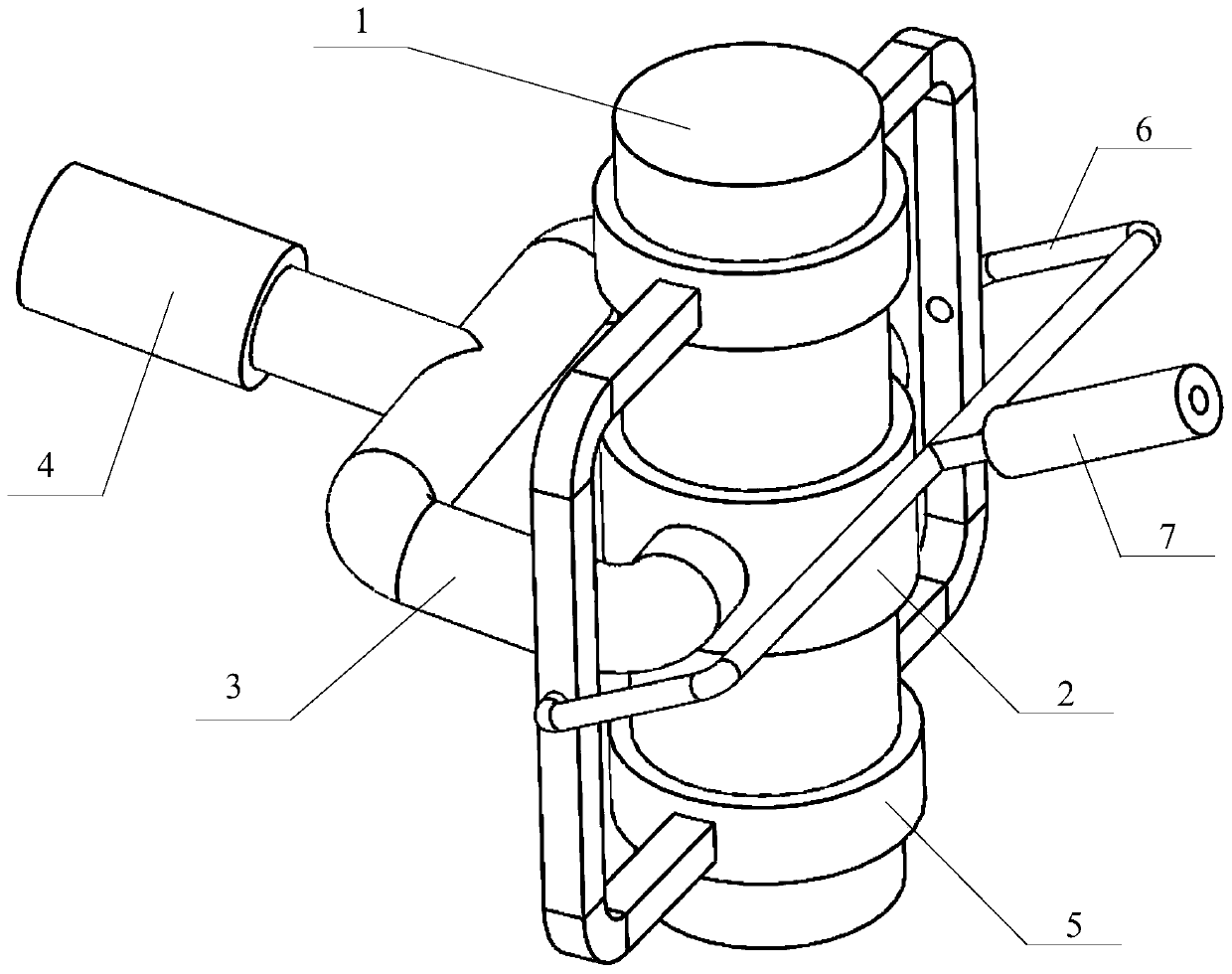

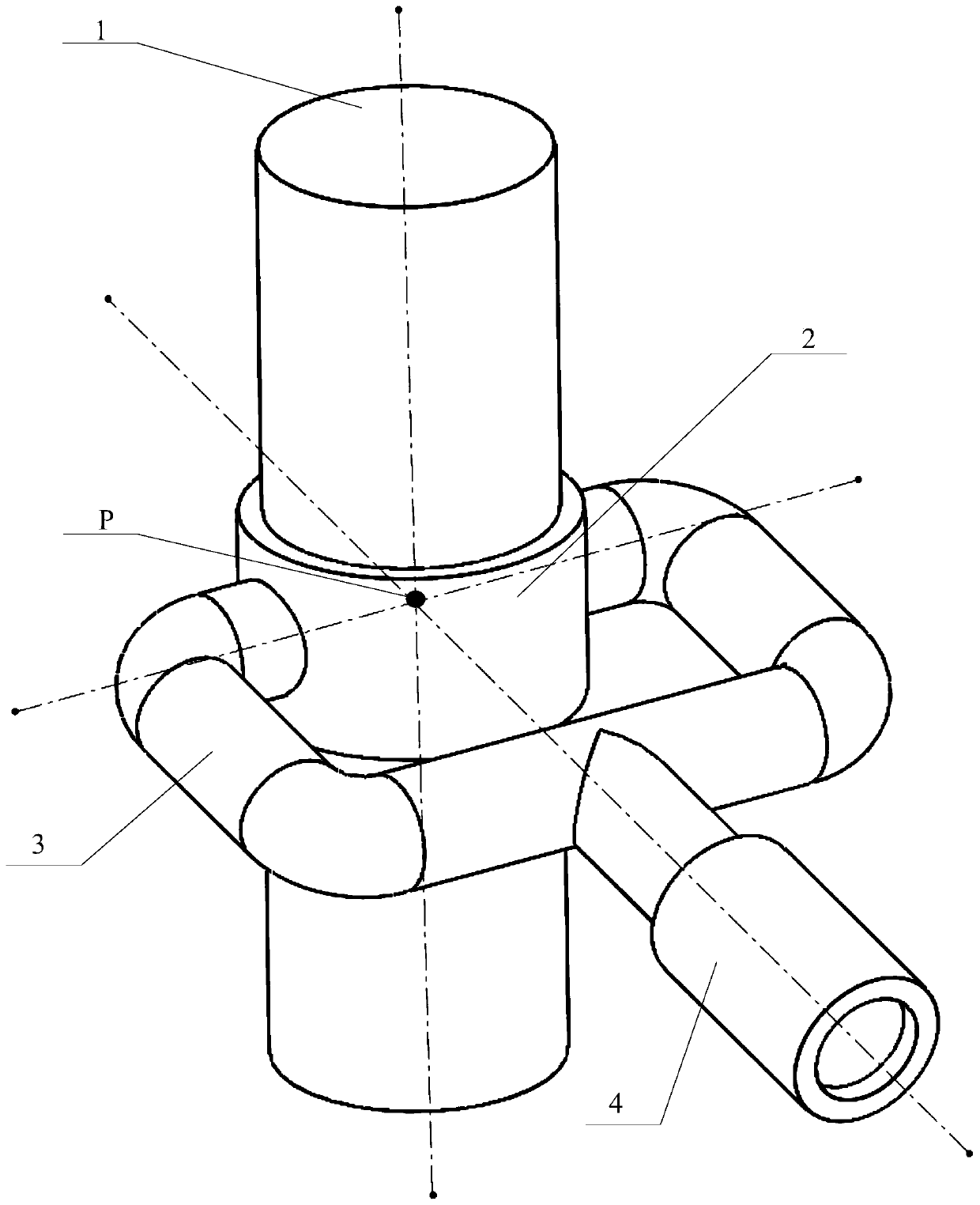

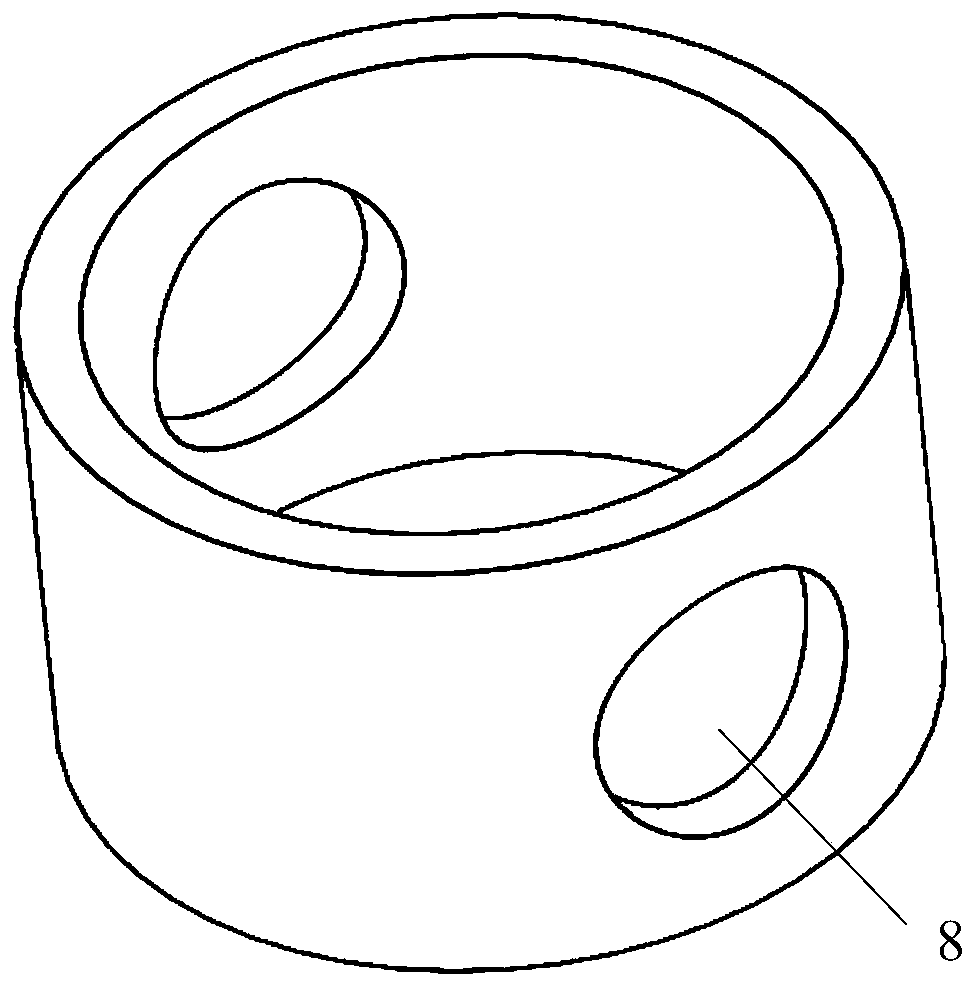

[0032] Such as Figure 1 to Figure 6 As shown, a compound ball hinge includes a central column 1 and a first-layer hinge and a second-layer hinge arranged on the central column 1, the first-layer hinge is arranged between the first member and the second member, and the second-layer The hinge is arranged between the first member and the third member. The first hinge and the second hinge are general ball hinges, both of which have three rotation axes, and the three rotation axes are perpendicular to each other. The three rotation axes of the first hinge always intersect. At the same point P, the three rotation axes of the second-layer hinge always intersect at the same point Q. During actual assembly, point P and point Q coincide. Wherein, the first hinge is composed of a first sleeve 2, an inner fork 3 and a first sliding column 4, the first sleeve 2 is arranged at the middle section of the central column 1, and the inner fork 3 is connected to the first sleeve 2 , the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com