Descending linkage self-adjusting annular cutting structure

A self-adjusting and ring cutting technology, applied in metal processing and other directions, can solve problems such as insufficient semi-automation, and achieve the effect of high work efficiency, flexible control and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

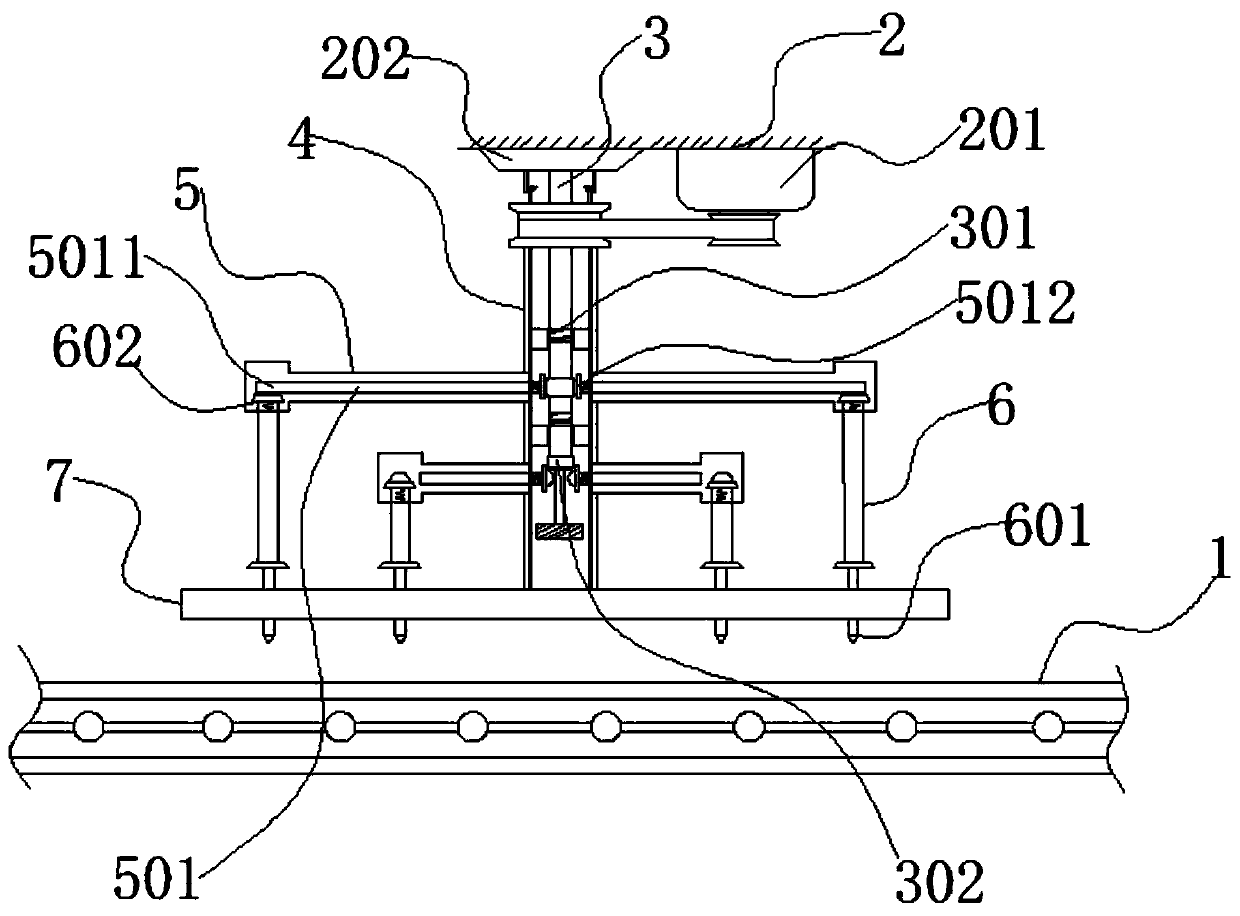

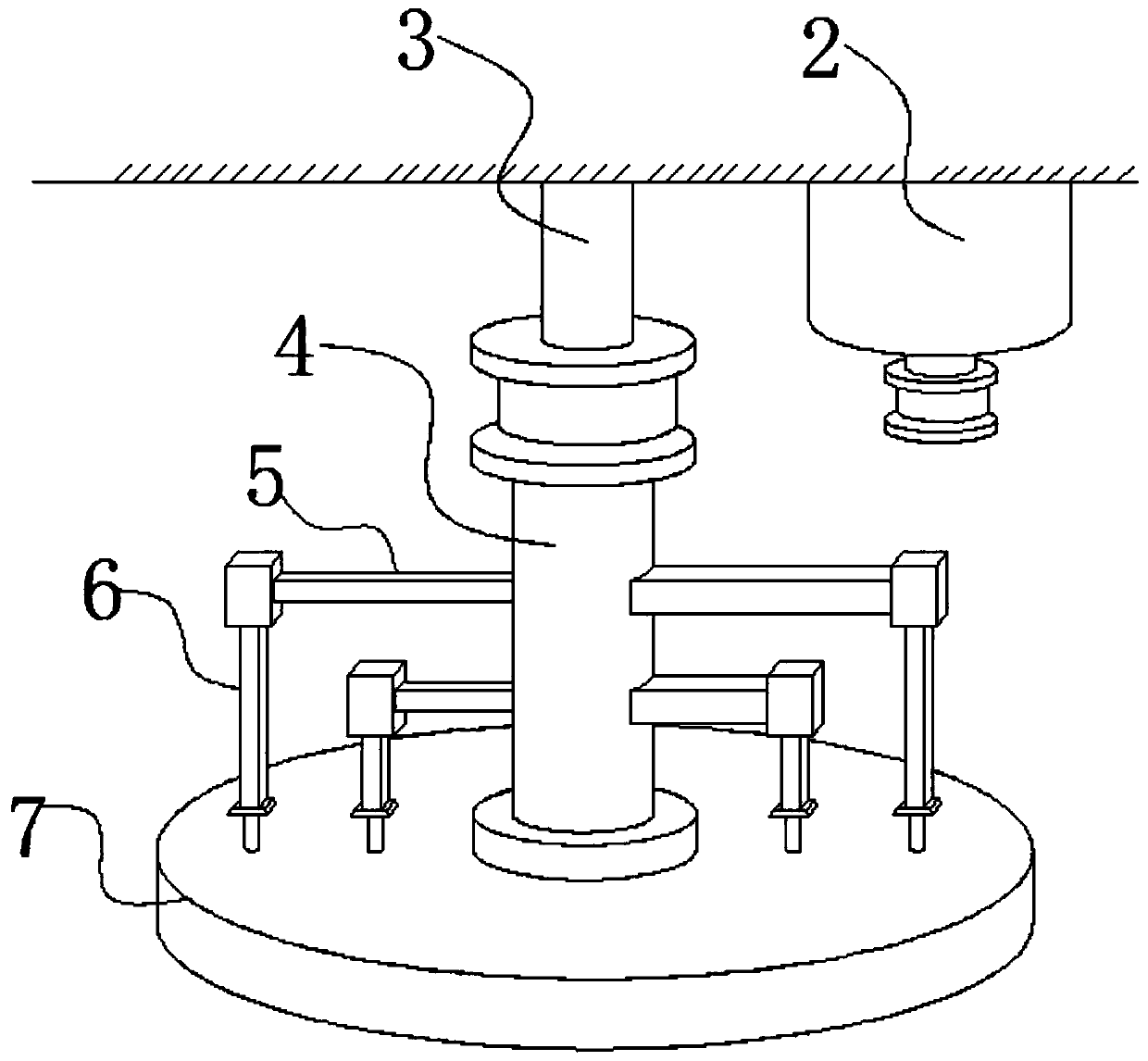

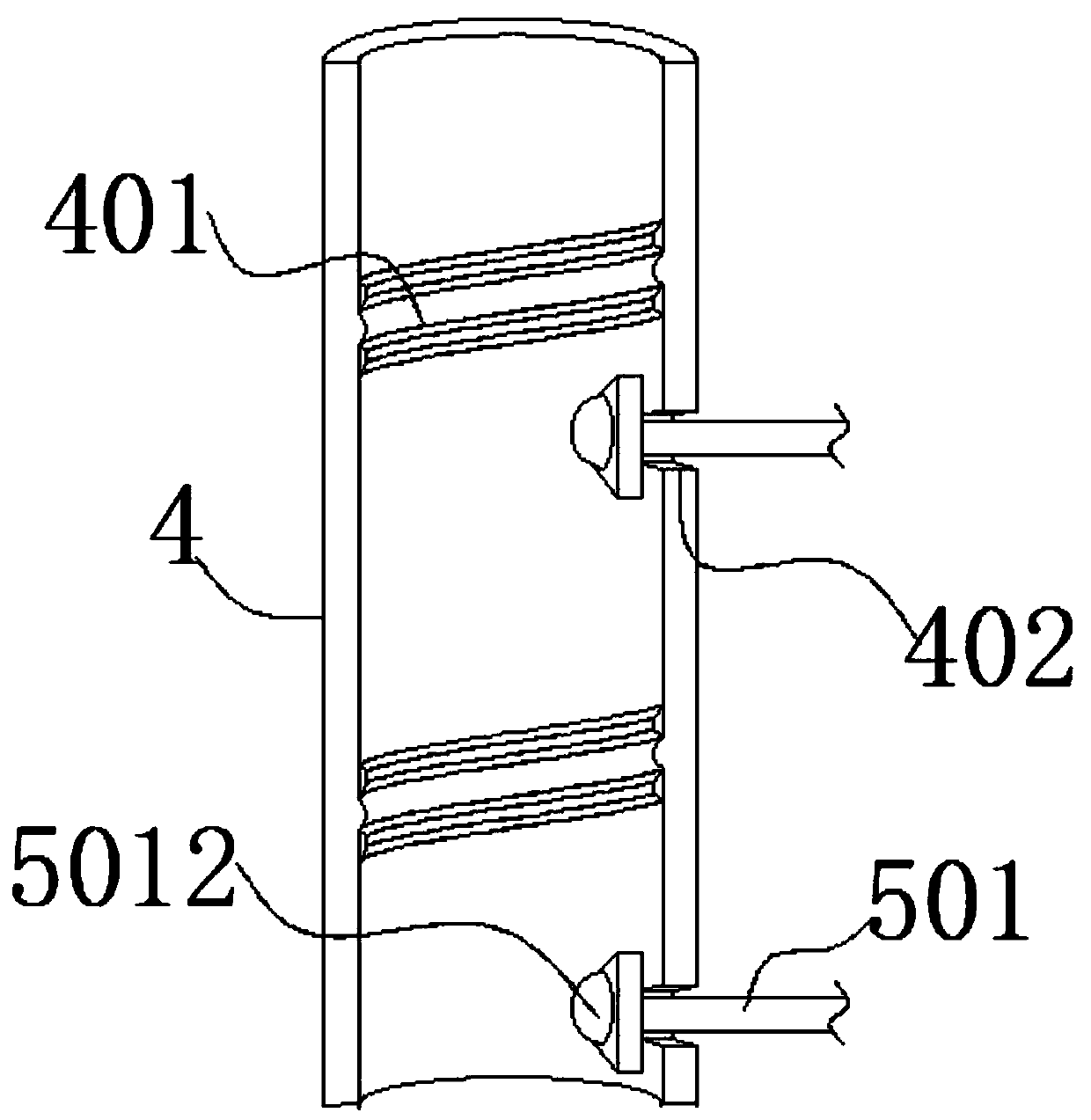

[0031] as attached figure 1 to attach Figure 6 Shown:

[0032] The present invention provides a downward linkage self-adjusting ring cutting structure, which includes an orientation shaft 3, a telescopic collar 4, a truss plate 5, a longitudinal rod 6, a positioning plate 7, an active sliding wire 301, a raised 302, passive sliding wire 401, Unicom port 402, transmission rod 501, cutting head 601, first passive part 602, pressurization groove 5011 and second passive part 5012; positioning disc 7 is movably connected with longitudinal rod 6, longitudinal rod 6 The upper and lower ends are respectively fixedly connected with the first passive part 602 and the cutting head 601. The first passive part 602 is nested with a truss plate 5, and the truss plate 5 is movably connected with a transmission rod 501, and the two sides of the transmission rod 501 are respectively integrated. A pressurization groove 5011 and a second passive part 5012 are provided, the other side of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com