A kind of preparation method of lightweight and environment-friendly high-speed train plug door cover plate

A high-speed train, environmentally friendly technology, applied in the field of rail transit, can solve the problems of human health hazards, cannot be decomposed, and cannot be degraded by FRP materials, and achieves the effect of achieving firm bonding and overcoming poor contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

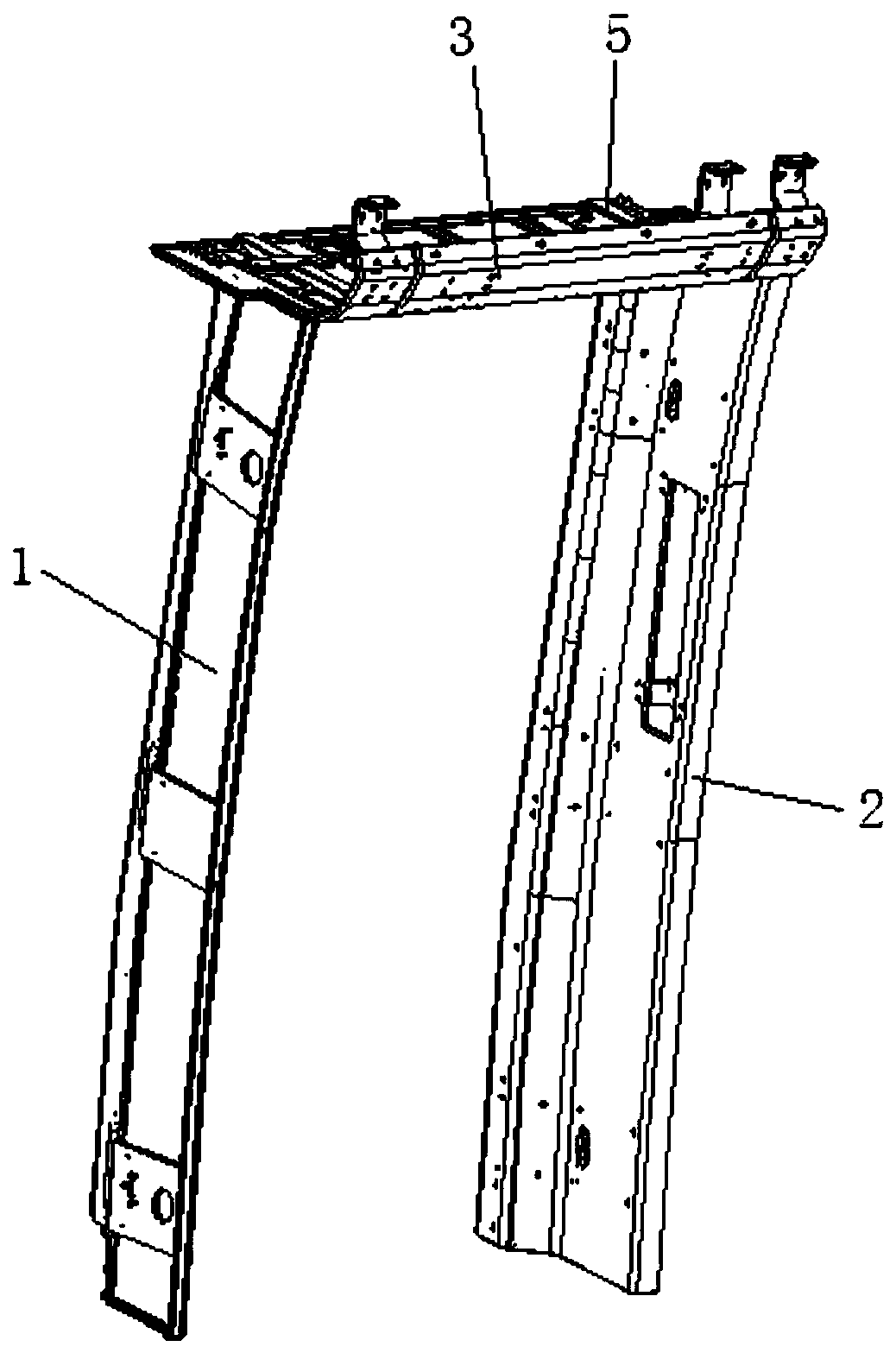

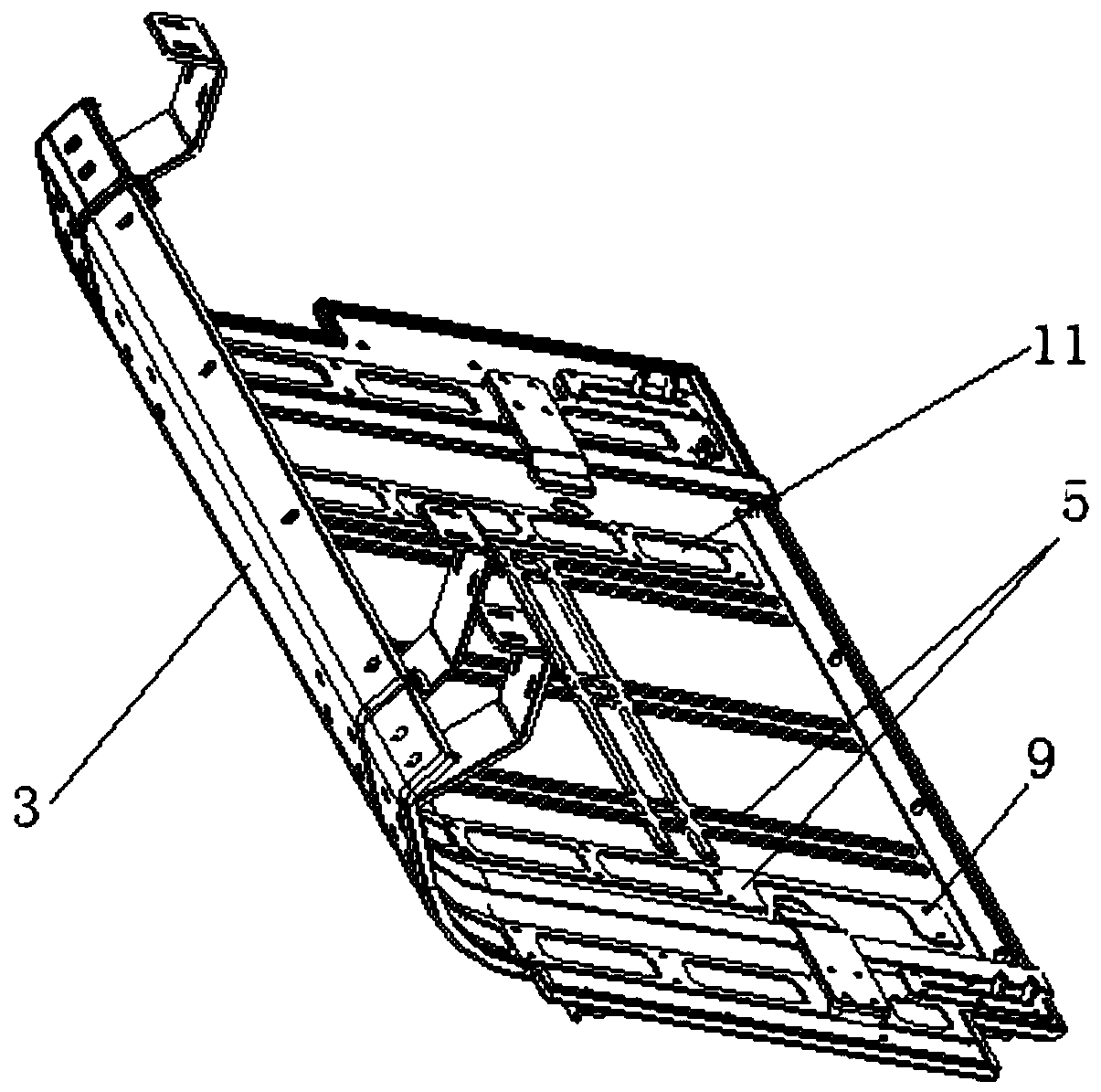

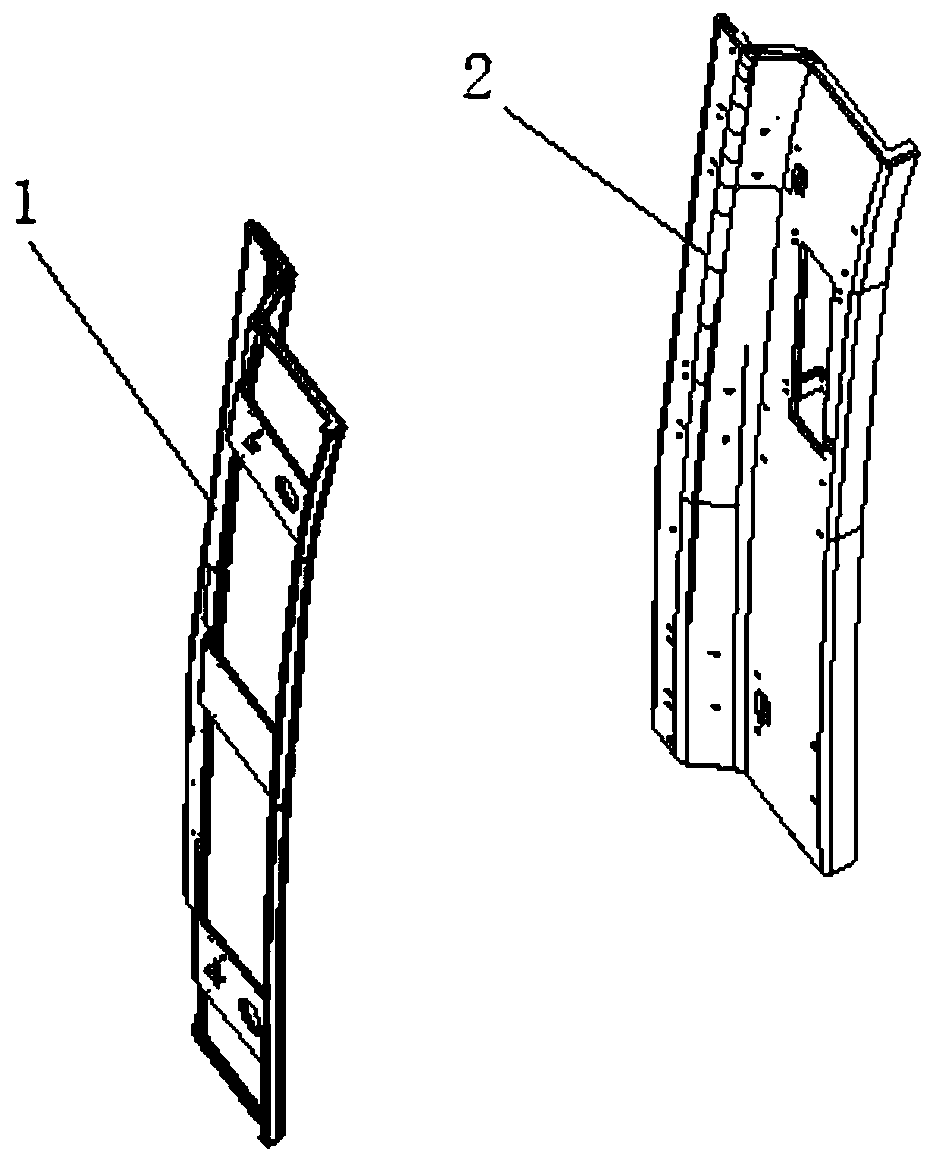

[0068] Such as Figures 1 to 9 Shown is the embodiment of a kind of lightweight environment-friendly type high-speed train plug door cover plate of the present invention, comprises left door cover plate 1, right door cover plate 2 and bridges on described left door cover plate 1, right door cover plate The top door cover plate 3 at the top of the plate 2; wherein, the left door cover plate 1, the right door cover plate 2, and the top door cover plate 3 are respectively the left door cover plate 1 and the right door cover plate 2 formed by the molded hemp fiber composite plate 4 , the top door cover plate 3, and metal reinforcing ribs 5 are respectively connected to the backs of the left door cover plate 1, the right door cover plate 2, and the top door cover plate 3; The front layer 6, the middle layer 7 and the back layer 8, the middle layer 7 is a hemp fiber felt layer made of mixed fibers of hemp fiber and polypropylene fiber, and the front layer 6 and the back 8 layers are...

Embodiment 2

[0082] Such as Figures 1 to 9 Shown is a kind of embodiment of the preparation method of light-weight environment-friendly high-speed train plug door cover plate, comprises the steps:

[0083] The first step, prefabricated hemp fiber composite board;

[0084] The second step, prefabricated metal reinforcement 5;

[0085] The third step is to use the forming die 12 to position the metal reinforcement rib 5 in the forming die 12, and to preheat simultaneously with the forming die 12; wherein, the forming die 12 includes a left door cover plate forming die , right door cover plate forming die, top door cover plate forming die; wherein, on the forming die 12, a positioning groove 13 is excavated on the molding surface located at the back of the plug door cover plate, and the metal reinforcing rib 5 Embedded in the positioning groove 13 through clearance fit;

[0086] The fourth step is to heat and soften the hemp fiber composite board, and then put it into the corresponding mo...

Embodiment 3

[0109] Carry out a performance test for a kind of lightweight environment-friendly high-speed train plug door cover plate (not containing metal reinforcing rib 5) manufactured by above-mentioned embodiment 1 and 3, obtain result as follows:

[0110]

[0111]

[0112]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com