Low-floating-fiber continuous long glass fiber reinforced polypropylene composite material and preparation method and application thereof

A composite material and polypropylene technology, which is applied in the field of low-floating fiber continuous long glass fiber reinforced polypropylene composite material and its preparation, can solve the problems such as the inability to achieve low-floating fiber effect, the inability to apply in the automotive field, and the low amount of glass fiber added. , to achieve the effect of improving the serious problem of floating fiber, good infiltration and coating effect, and long flow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments.

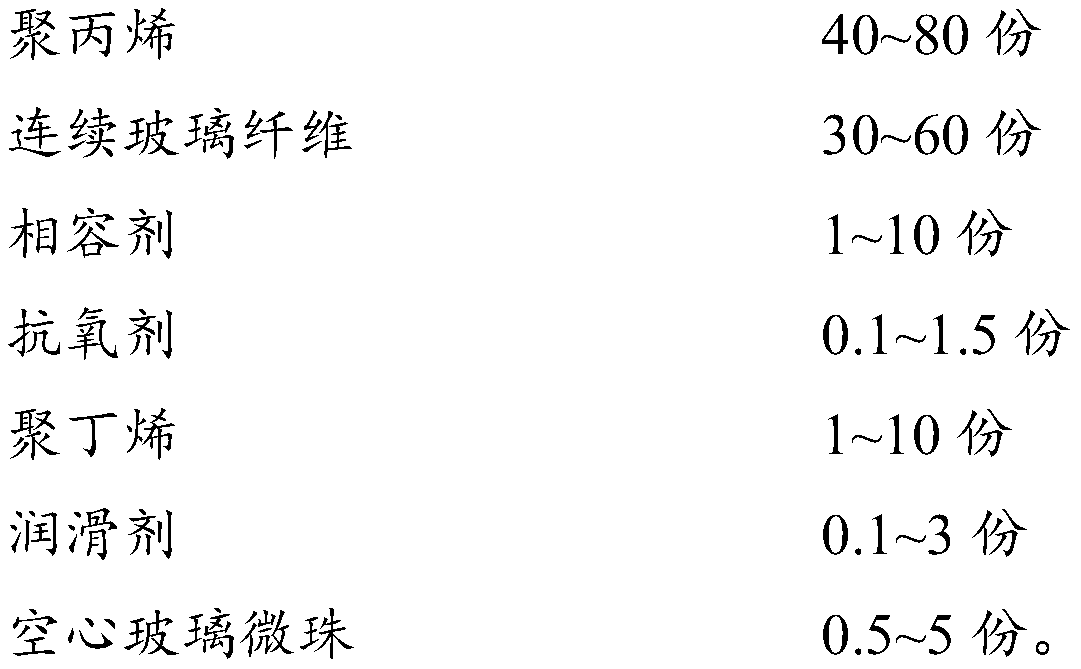

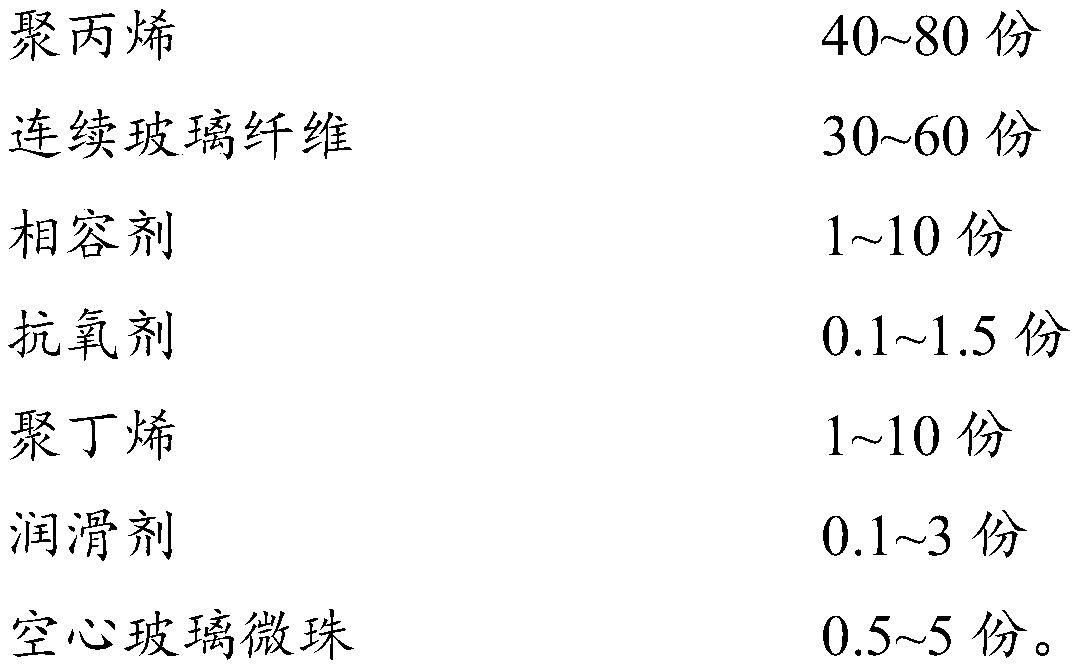

[0035] The low-floating fiber continuous long glass fiber reinforced polypropylene composite material of the present invention, the raw material ratios of Examples 1-6 and Comparative Examples 1-2 are shown in Table 1 and Table 2, unless otherwise specified, parts refer to parts by weight .

[0036] Low floating fiber continuous long glass fiber reinforced polypropylene composite material, comprising the following steps:

[0037] (1) Mix polypropylene and other additives uniformly in a high-speed mixer at a speed of 500-3000r / min for 5-20 minutes to obtain a mixed material;

[0038] (2) Put the mixed material in the step (1) into the feed port of the twin-screw extruder of the long fiber equipment for melt extrusion, and introduce the continuous glass fiber into the impregnation die through the glass fiber frame of the long fiber equipment, and carry out The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com