Biodegradable fertilizer efficiency agricultural film as well as preparation method and application thereof

A technology for biodegradation and biodegradation of polyester is applied in the field of fertilizer-efficiency agricultural film and its preparation, which can solve the problems of high cost of biodegradable film materials, and achieve the effects of being beneficial to product promotion, low production cost, and improving the problem of difficult dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

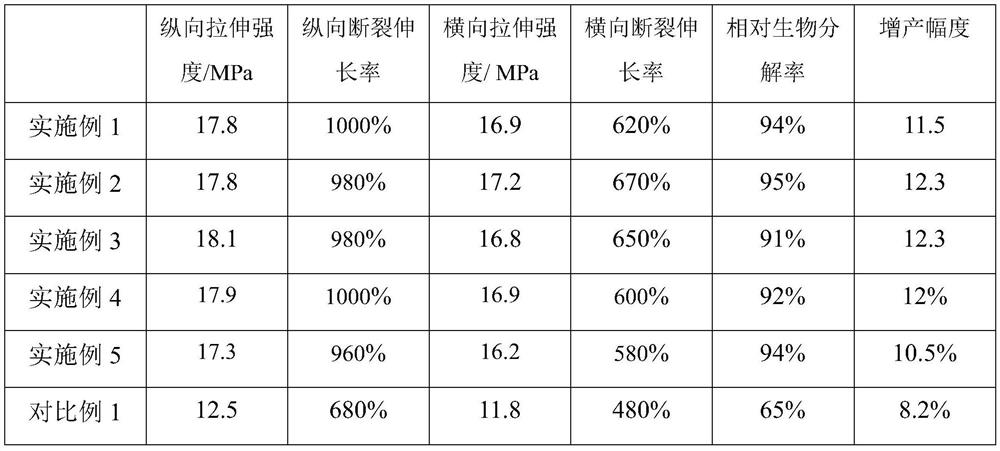

Examples

Embodiment 1

[0038] Step S1, adding biodegradable polyester and surface-modified phosphate rock powder into a high-speed mixer, stirring and mixing to obtain a mixture, and the surface-modified phosphate rock powder is prepared by the following process:

[0039] Step S11, grinding the phosphate rock into powder with a particle size to obtain phosphate rock powder;

[0040] Step S12, adding fatty acid into phosphate rock powder, and performing mixing reaction at a certain temperature in a high-speed mixer to obtain fatty acid modified phosphate rock powder, wherein the mass ratio of fatty acid to phosphate rock powder is 1:100, and the mixing reaction temperature is 80 ℃, the mixing reaction time is 0.5h;

[0041] Step S13, adding the epoxy compound into the fatty acid-modified phosphate rock powder, and performing a mixing reaction at a certain temperature in a high-speed mixer to obtain a surface-modified phosphate rock powder, wherein the mass ratio of the epoxy compound to the fatty aci...

Embodiment 2

[0046] The operation steps are as shown in Example 1, wherein the mass ratio of biodegradable polyester, surface-modified phosphate rock powder and fully biodegradable color masterbatch is 70:25:1.

[0047] In the step S12, the mass ratio of fatty acid to phosphate rock powder is 10:100,

[0048] In the step S13, the mass ratio of the epoxy compound to the fatty acid is 5:1.

Embodiment 3

[0050] The operation steps are as shown in Example 1, wherein the mass ratio of biodegradable polyester, surface-modified phosphate rock powder and fully biodegradable color masterbatch is 94.9:40:1.

[0051] In the step S12, the mass ratio of fatty acid to phosphate rock powder is 20:100,

[0052] In the step S13, the mass ratio of the epoxy compound to the fatty acid is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com