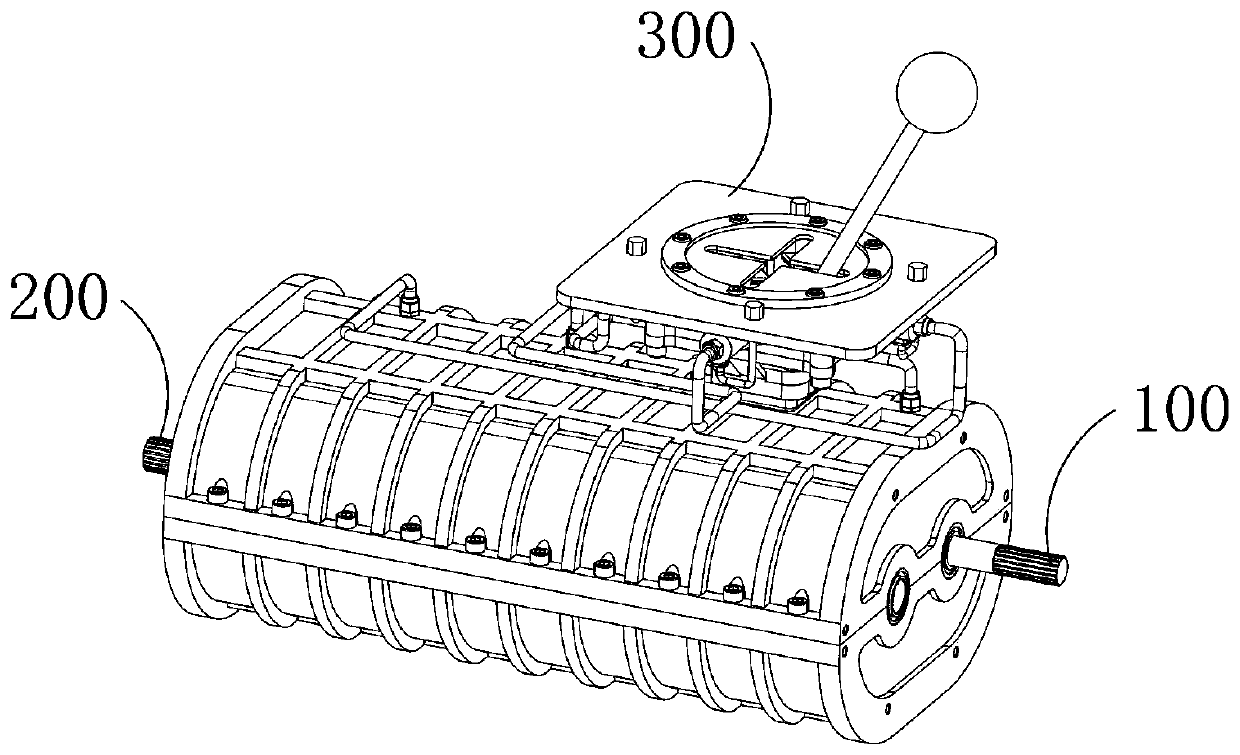

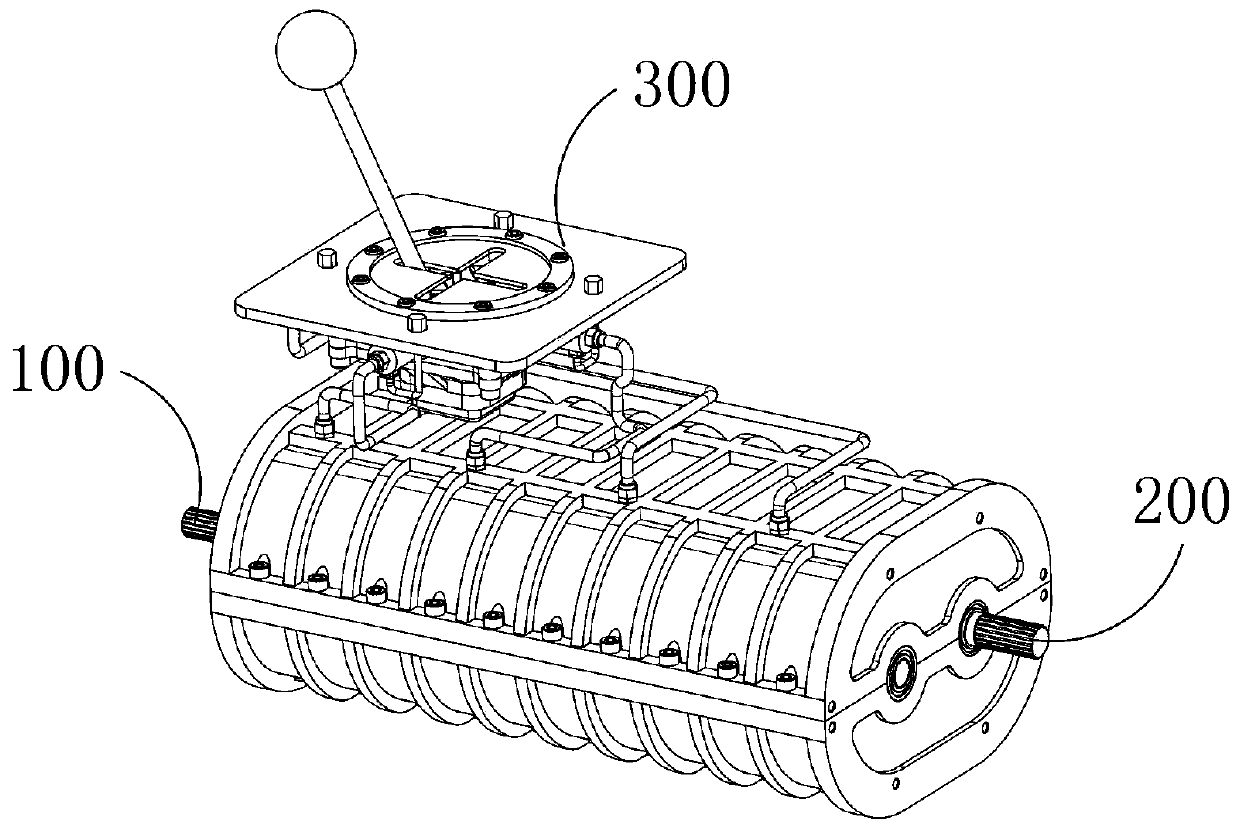

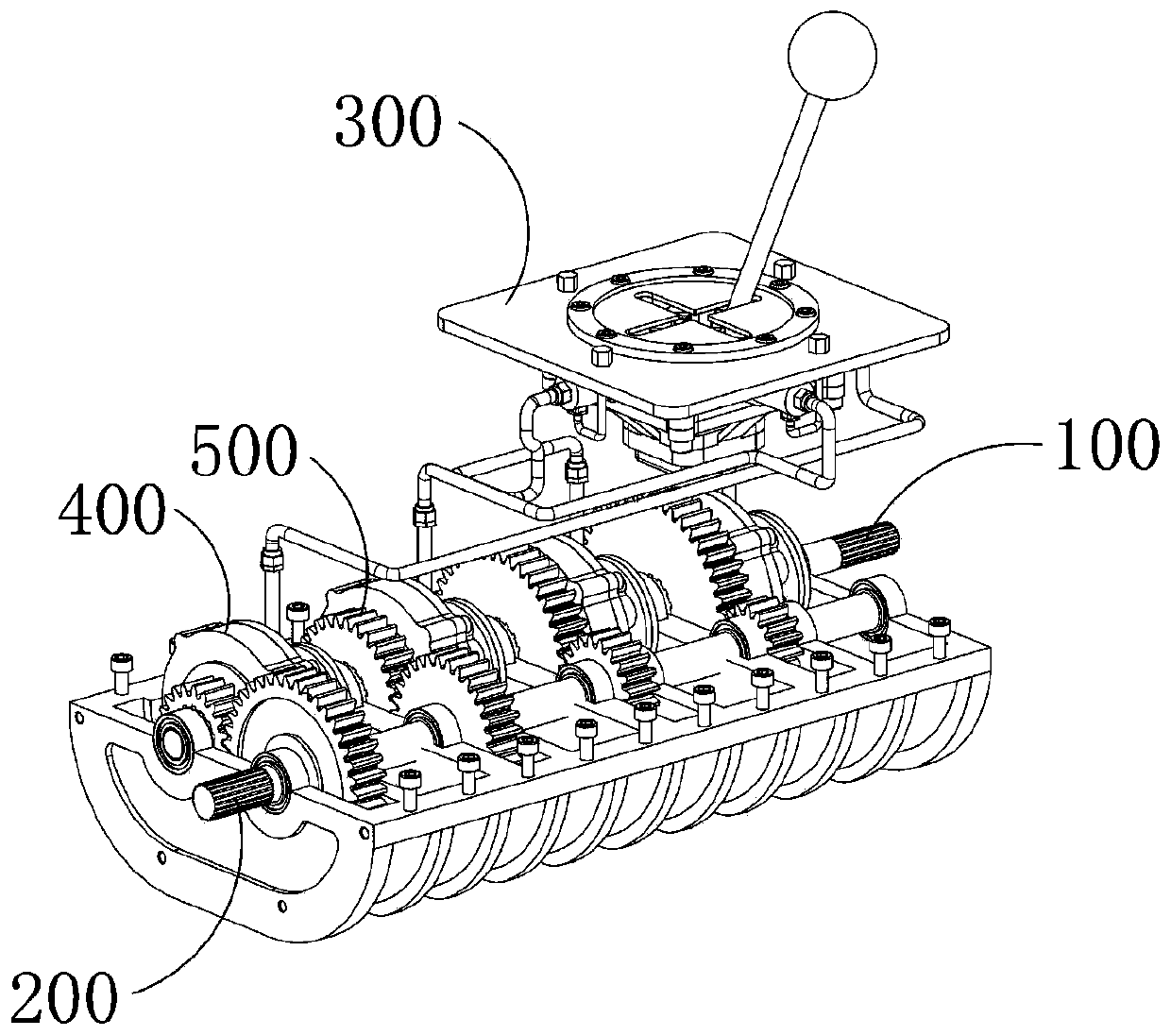

Automobile gearbox adopting clutch hydraulic shifting method

A kind of automobile gearbox and hydraulic technology, applied in the direction of components with teeth, transmission control, belt/chain/gear, etc., can solve problems such as unsatisfactory, large vibration amplitude of the gear lever, and reduced operating comfort. The blocking process is smooth and smooth, and the transmission process is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention has the advantage of adopting the clutch hydraulic method for shifting gears that it can make the shifting process more stable and smooth, and the hydraulic oil transmission method is adopted between the shifting device and the gear device. Compared with the traditional connecting rod linkage transmission method, the transmission The process is smoother. At the same time, the transmission of hydraulic oil can make the installation position selection of the shift device and the gear device in the car more diverse. In addition, during the shifting process of the gear device, the input shaft and the gear mechanism The power transmission is carried out through the clutch, so that the gears in the gear mechanism do not need to be displaced axially, and the gear sets in the gear mechanism have no wear except for the unavoidable wear during meshing rotation, and compared with the transmission gear mechanism, there is no shifting The impact generated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com