Novel oil seal

A new type of oil seal technology, applied in engine seals, engine components, mechanical equipment, etc., can solve problems such as large friction temperature rise and friction torque, accelerate lip and shaft wear, reduce oil seal life, etc., to achieve lower requirements and lower Oil seal sealing requirements, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

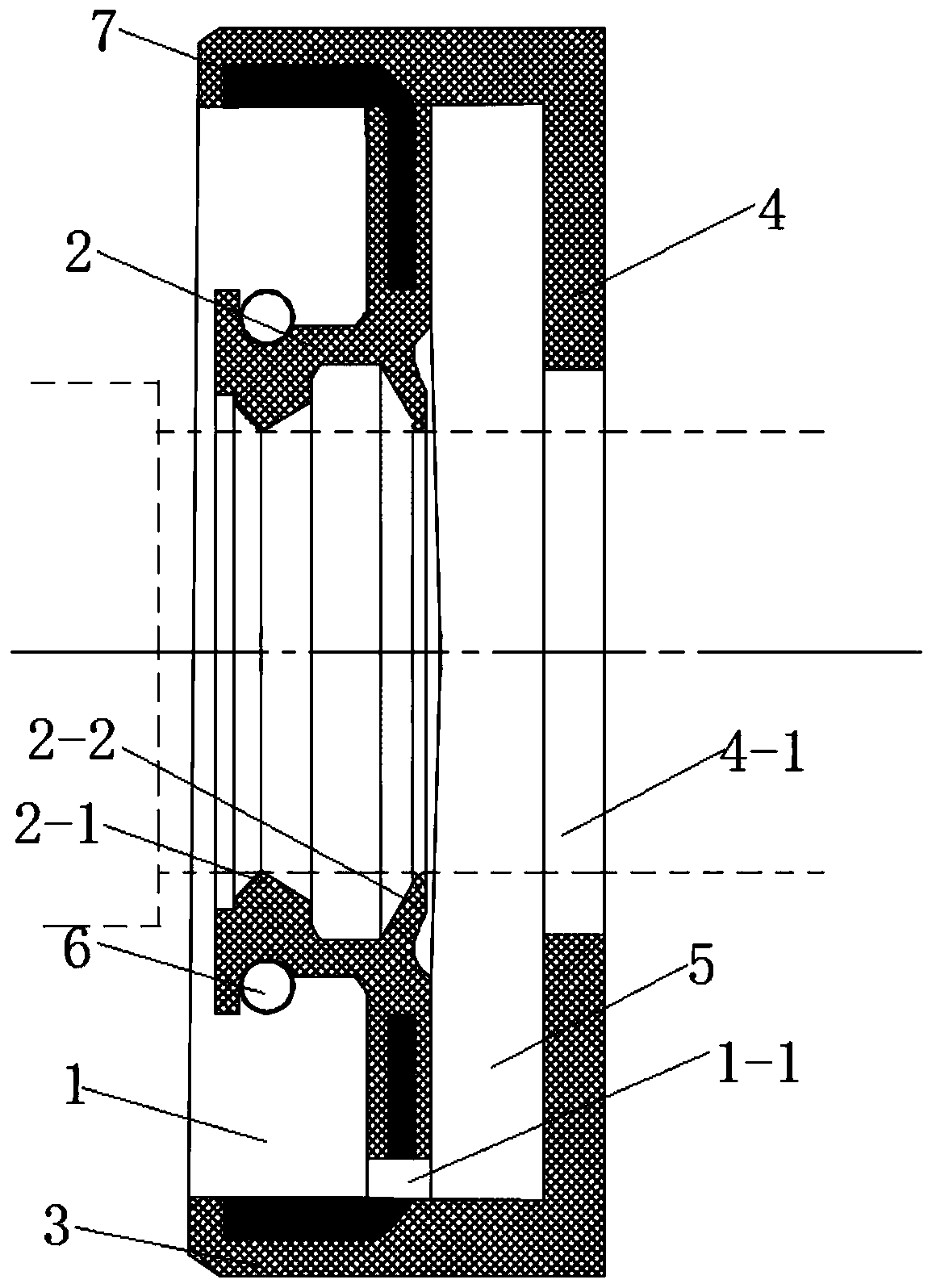

[0023] combine figure 1 , a new type of oil seal of the present invention, comprising an oil seal body, the oil seal body is an annular structure with a U-shaped groove 1 on the end surface, and an inner ring 2 is formed on the oil seal body to hold tightly on the rotating shaft and is used to fit and install in the shaft hole The inner outer ring 3 and inner ring 2 are provided with at least one protruding ring-shaped sealing lip 2-1; the outer ring surface of the inner ring 2 is provided with an annular spring mounting groove. A spring 6 that acts as a clamp is installed in the annular spring installation groove; a dust-proof lip 2-2 for contacting with the rotating shaft and sealing is provided on the inner circular surface of the inner ring 2; the outer ring 3 and the U-shaped groove The inside of the groove bottom of 1 is inlaid with a metal skeleton 7; the bottom of the U-shaped groove 1 is provided with an oil return hole 1-1; the outer surface of the groove bottom of t...

Embodiment 2

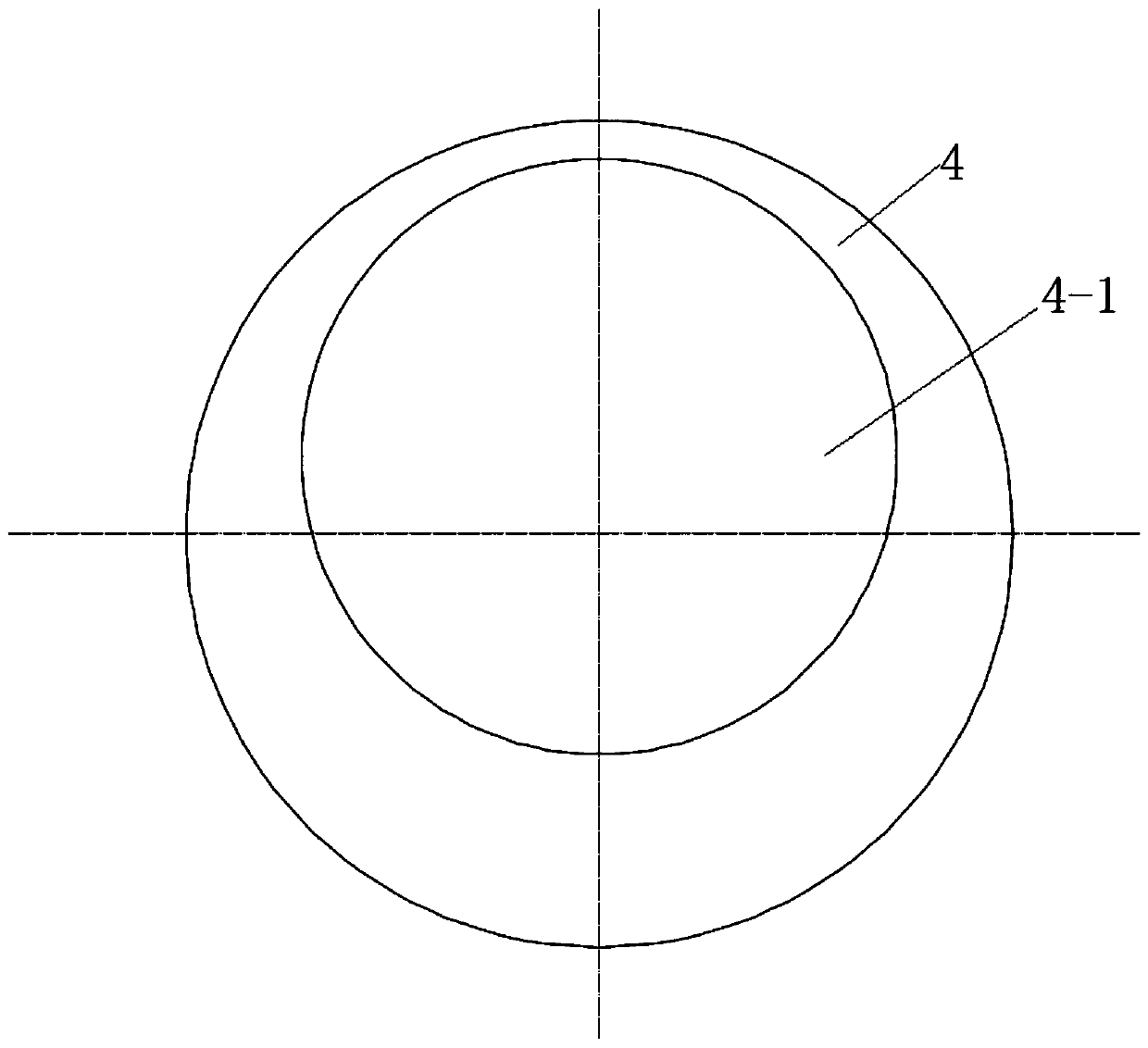

[0025] combine figure 2 with image 3 , the basic structure of a new type of oil seal of the present invention is the same as that of Embodiment 1, the difference is that the cover body 4 is in a circular structure, and the bottom wall of the cover body 4 is provided with an eccentric setting that does not hinder the assembly of the oil seal body on the rotating shaft. Hole 4-1 saves manufacturing materials while ensuring the normal operation of the secondary reflow "seal" structure.

Embodiment 3

[0027] combine image 3 , The basic structure of a new type of oil seal of the present invention is the same as that of Embodiment 1, the difference is that the cover body 4 is in an inferior arc shape, which further saves manufacturing materials while ensuring the normal operation of the secondary return "seal" structure.

[0028] A new type of oil seal of the present invention has a simple structure and ingenious design. Two seals are designed on the oil seal by using the design concept of combination of escapement and escapement, and the second open seal is activated when the first closed seal fails. , to achieve a "seal" that never leaks oil. In addition, due to the existence of the second open seal, it also greatly reduces the requirements for the manufacture of hermetic seals for oil seals, and greatly reduces the manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com