Material placement frame for freeze dryer

A freeze-drying machine and placing rack technology, applied in the field of freeze-drying machines, can solve the problems of inability to adjust the bracket, the freeze-drying machine is cumbersome, and has low applicability, and achieves the effects of easy production, reduced self-weight, and strong applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

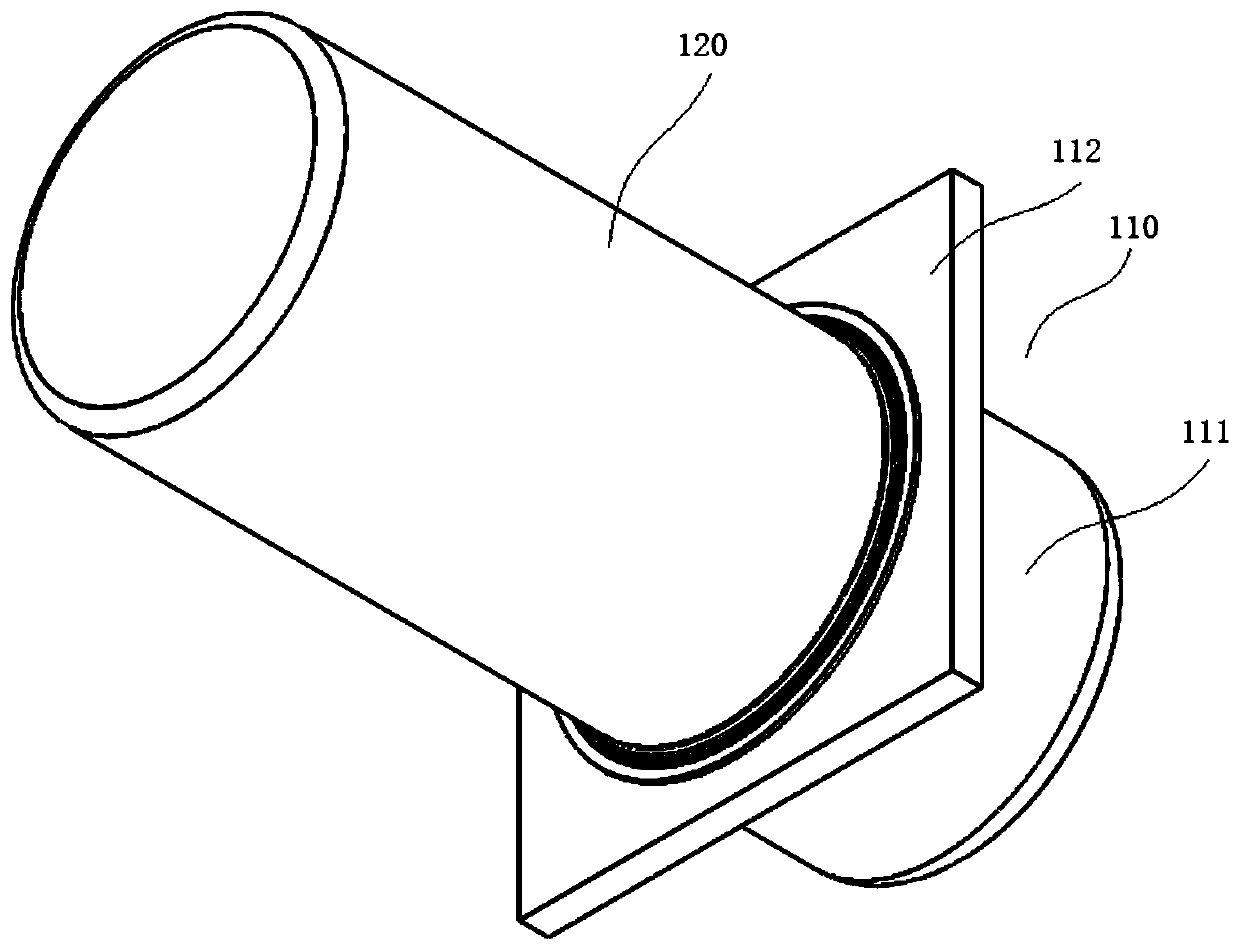

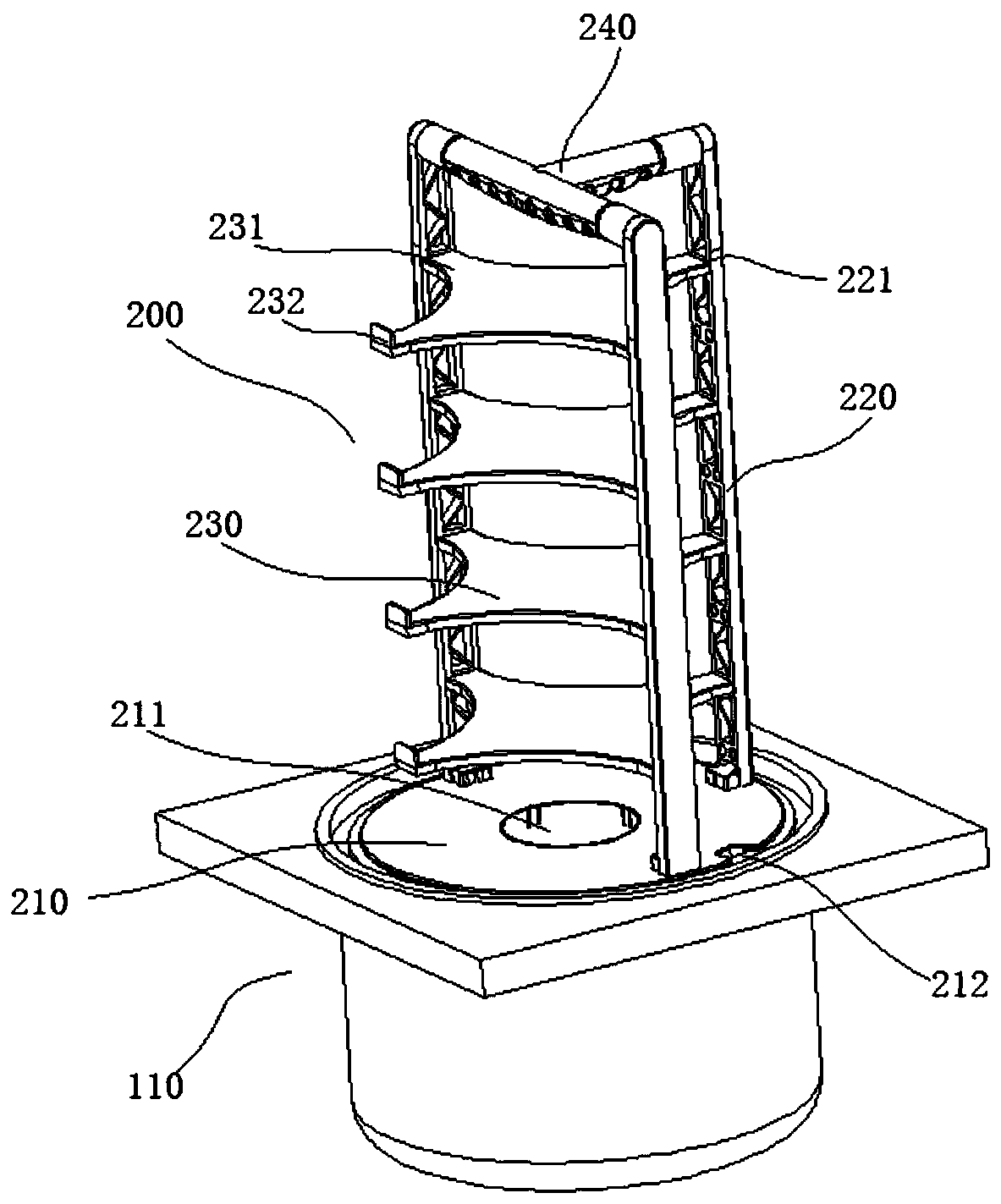

[0033] Such as Figure 1-13 As shown, the present embodiment provides a material placement rack for a freeze dryer, which includes a bracket body 200 of plastic material for being arranged at the cold hydrazine 110. A transparent sealing cover 120 for sealing.

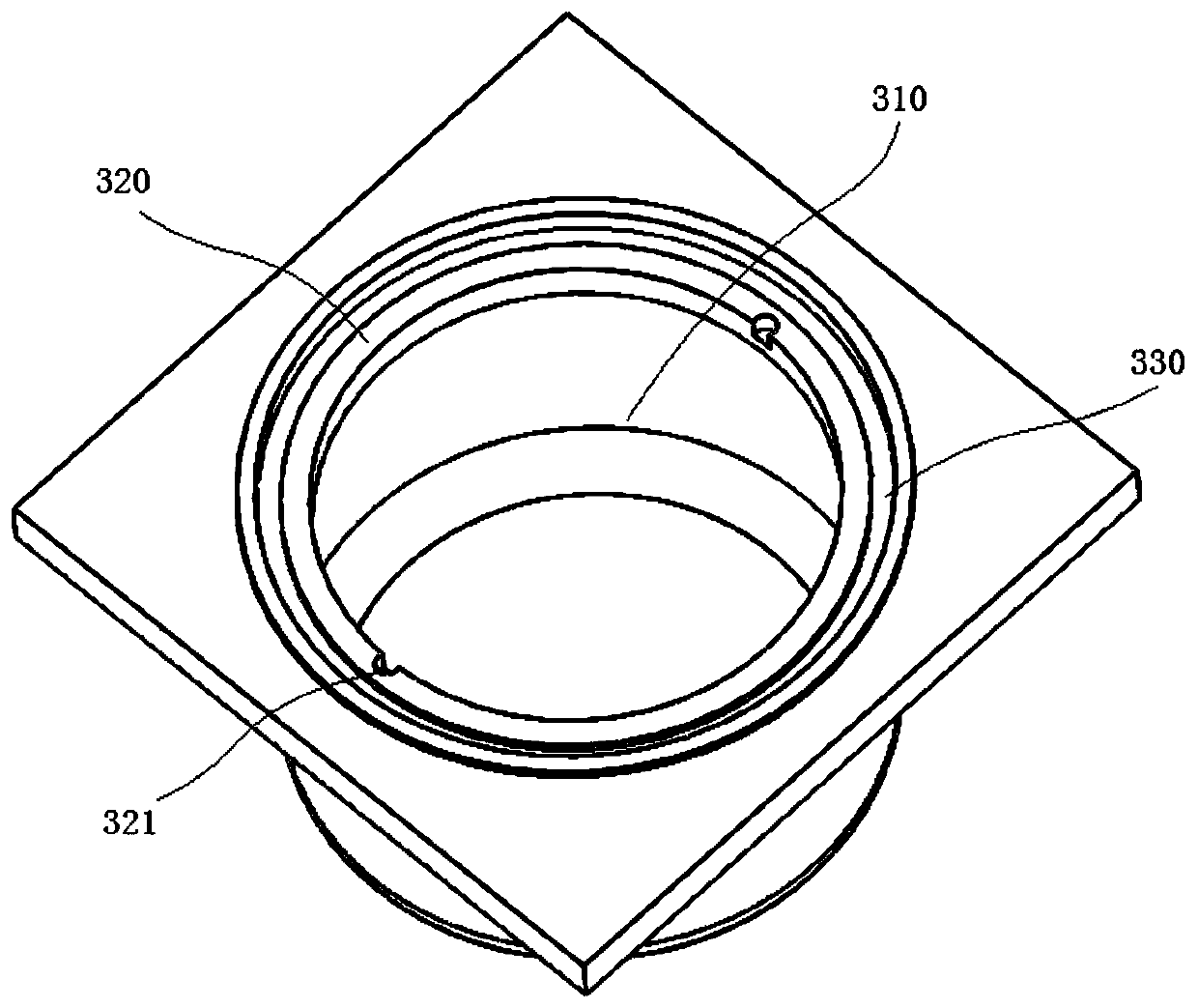

[0034] combine figure 2 and 3 As shown, the cooling valve 110 includes a cooling housing 111, the upper end of the cooling housing 111 forms a cooling opening 310, and the lower end of the bracket body 200 is arranged at the cooling opening 310; At the opening 310, the bottom plate 210 is provided with a diversion port 211 communicating with the inner cavity of the cold hydrazine housing 111; the upper edge of the bottom plate 210 is detachably provided with three uprights 220 vertically, and the horizontal between the three uprights 220 There is at least one tray 230 ; the tray 230 is provided with a pin portion 231 corresponding to any column 220 , and the column 220 is provided with a plurality of socket portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com