Integral structure of oxygen gun muzzle brick of a non-ferrous smelting furnace

An overall structure, furnace oxygen lance technology, applied in the field of smelting equipment, can solve the problems of falling and damaged surrounding bricks and oxygen gun muzzle bricks, easy burning and breaking of iron wires, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

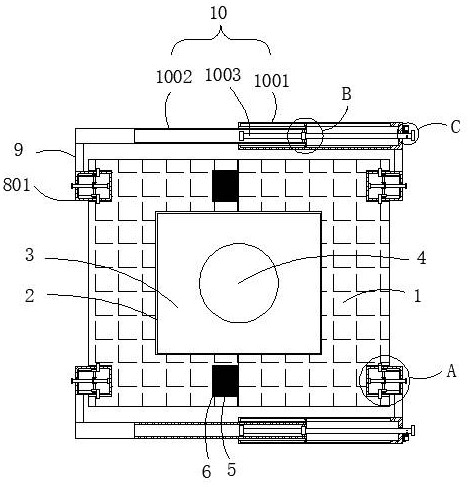

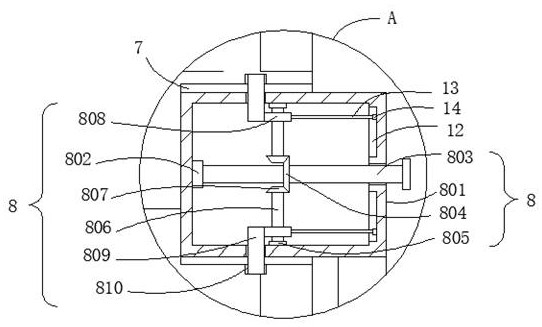

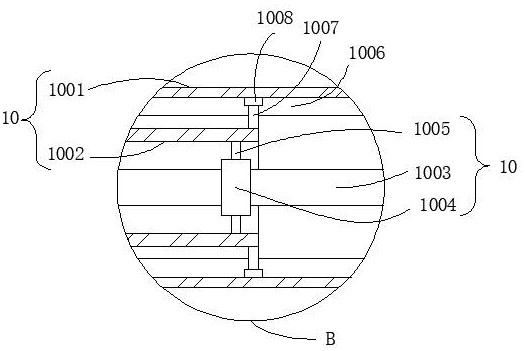

[0022] Refer Figure 1-4 An integrated structure of a colored smelting furnace oxygen gun, including two opposing white bricks 1, and the sidewalls of the two white bricks 1 have grooves 2, and the groove 2 is provided with an oxygen shot brick 3, And the oxygen guile 3 is opened, and the sidewalls of one of the sidewalls 1 are fixed to two limit blocks 5, and the two limit blocks 5 are located on both sides of the oxygen gun 3, and the other. The sidewall of the lacera 1 is opened with a restricted groove 6 that matches the limit block 5, and both sidewalls of the two sidewalls 1 are opened with a fixed groove 7, and a fixed mechanism 8 is provided in the fixed groove 7.

[0023] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com