Beam type crane and safety monitoring management system

A technology for beam cranes and safety monitoring, applied in the directions of walking bridge cranes, cranes, safety devices, etc., can solve the problems of cable pulling, affecting the efficiency of crane use, and the rope guide does not allow cable pulling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

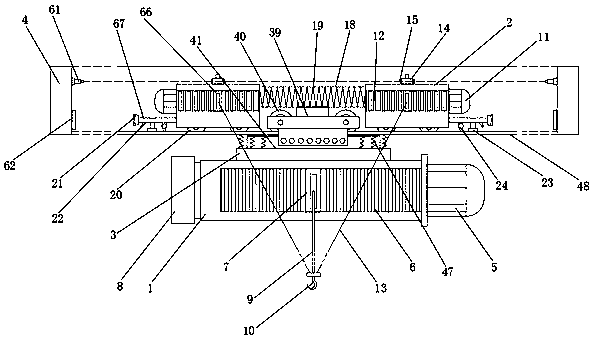

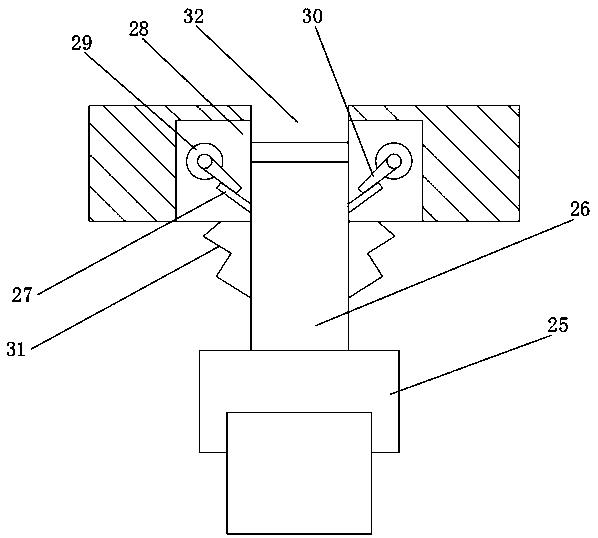

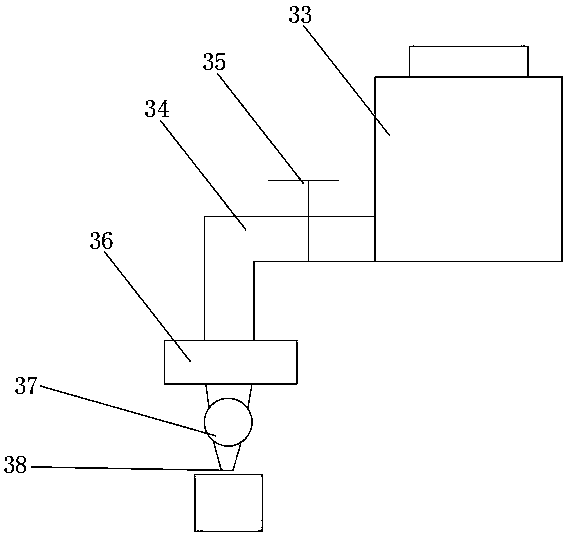

[0036]As shown in the drawings of the description, a girder crane and a safety monitoring and management system include hoisting equipment 1, auxiliary trolley 2, protection connection device 3, main girder 4, operating room 63, control system, cloud database 64 and remote management System 65; the main beam 4 is an inverted "H" beam, the horizontal frame is above the hoisting work surface, and the lower part is provided with a guide rail 48; the hoisting equipment 1 is arranged below the main beam 4; Four groups of auxiliary trolleys 4; the upper end of the protection connecting device 3 is arranged on the main beam 4, and the upper end is connected to the auxiliary trolley 2, and the lower end is connected to the winch equipment 1; the auxiliary trolley 2 includes a winding motor 11, Reel Ⅰ12, auxiliary sling 13, level inspection device 14, buffer spring cylinder 18, buffer spring 19, guide wheel Ⅰ20, anti-collision limit switch 21, trolley walking monitoring device 22, track...

Embodiment 2

[0040] As shown in the drawings of the description, a girder crane and a safety monitoring and management system include hoisting equipment 1, auxiliary trolley 2, protection connection device 3, main girder 4, operating room 63, control system, cloud database 64 and remote management System 65; the main beam 4 is an inverted "H" beam, the horizontal frame is above the hoisting work surface, and the lower part is provided with a guide rail 48; the hoisting equipment 1 is arranged below the main beam 4; Four groups of auxiliary trolleys 4; the upper end of the protection connecting device 3 is arranged on the main beam 4, and the upper end is connected to the auxiliary trolley 2, and the lower end is connected to the winch equipment 1; the auxiliary trolley 2 includes a winding motor 11, Reel Ⅰ12, auxiliary sling 13, level inspection device 14, buffer spring cylinder 18, buffer spring 19, guide wheel Ⅰ20, anti-collision limit switch 21, trolley walking monitoring device 22, trac...

Embodiment 3

[0045] As shown in the drawings of the description, a girder crane and a safety monitoring and management system include hoisting equipment 1, auxiliary trolley 2, protection connection device 3, main girder 4, operating room 63, control system, cloud database 64 and remote management System 65; the main beam 4 is an inverted "H" beam, the horizontal frame is above the hoisting work surface, and the lower part is provided with a guide rail 48; the hoisting equipment 1 is arranged below the main beam 4; Four groups of auxiliary trolleys 4; the upper end of the protection connecting device 3 is arranged on the main beam 4, and the upper end is connected to the auxiliary trolley 2, and the lower end is connected to the winch equipment 1; the auxiliary trolley 2 includes a winding motor 11, Reel Ⅰ12, auxiliary sling 13, level inspection device 14, buffer spring cylinder 18, buffer spring 19, guide wheel Ⅰ20, anti-collision limit switch 21, trolley walking monitoring device 22, trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com