Special-shaped fork arm-adopted resonant quartz tuning fork temperature sensor

A temperature sensor, quartz tuning fork technology, applied in the direction of thermometers, thermometers, and electrical devices that use electrical/magnetic components directly sensitive to heat, which can solve the problem of affecting the accuracy, consistency and stability of resonant quartz crystal temperature sensors , positioning accuracy and demanding optical cold processing technology, to achieve the effect of extending temperature working range and mechanical vibration and shock resistance, reducing leakage and parasitic vibration mode interference, and improving response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

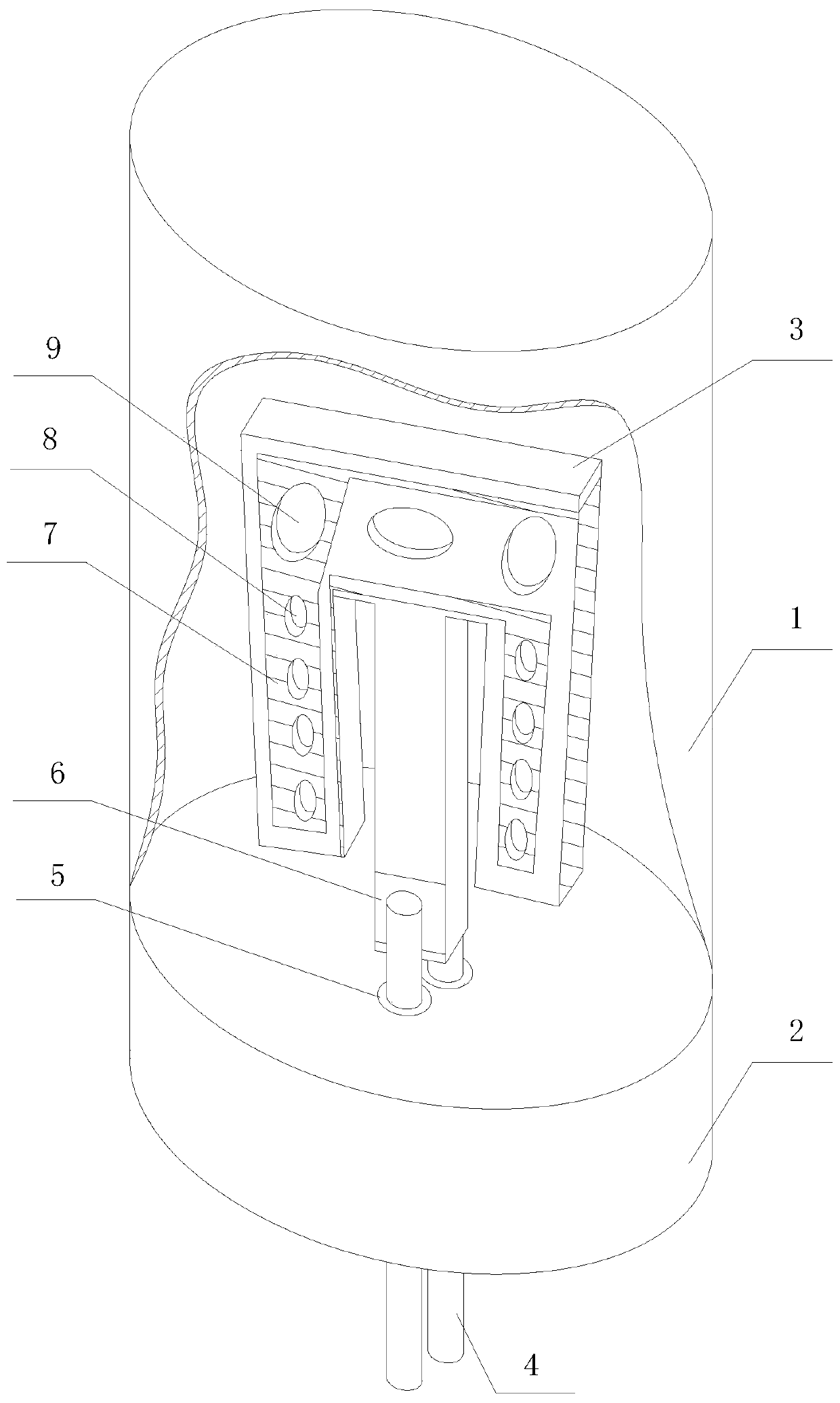

[0030] Specific implementation mode one: refer to figure 1 and figure 2 This embodiment is described in detail. A resonant quartz tuning fork temperature sensor using a special-shaped fork described in this embodiment includes: a tube cap 1, a tube base 2, a quartz tuning fork thermal resonator 3 and an insulator, and the tube cap 1 covers Closed on the upper surface of the tube base 2, forming a sealed space between the two, the top of the insulator extends through the tube base 2 into the inside of the sealed space, and the quartz tuning fork thermal resonator 3 is located in the sealed space;

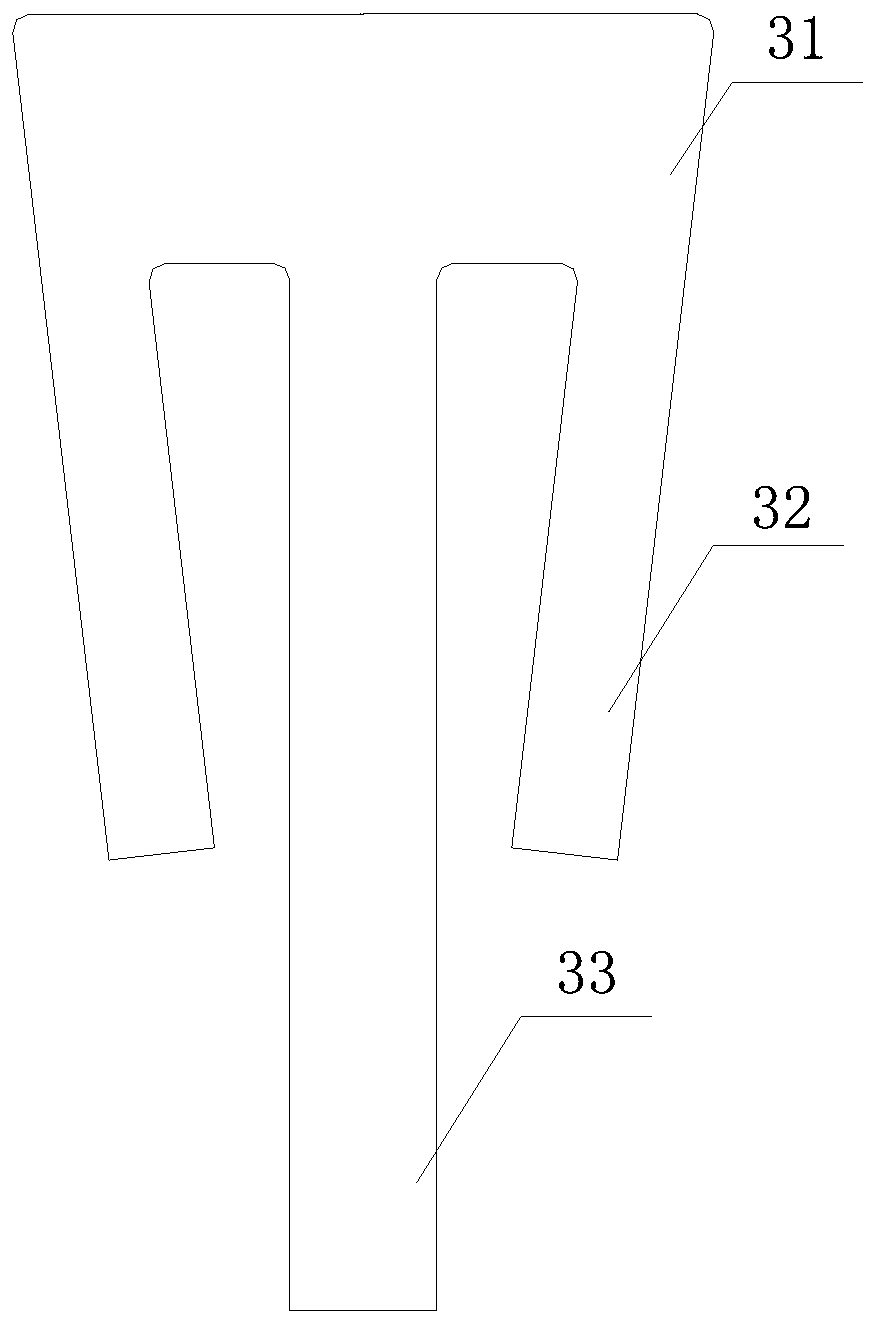

[0031] Such as figure 2 As shown, the quartz tuning fork thermosensitive resonator 3 of the present embodiment includes a connecting portion 31, two fork arms 32 and a base portion 33; the head ends of the two fork arms 32 are connected to the head end of the base portion 33 through the connecting portion 31, and The two fork arms 32 and the base portion 33 are located on the sa...

specific Embodiment approach 2

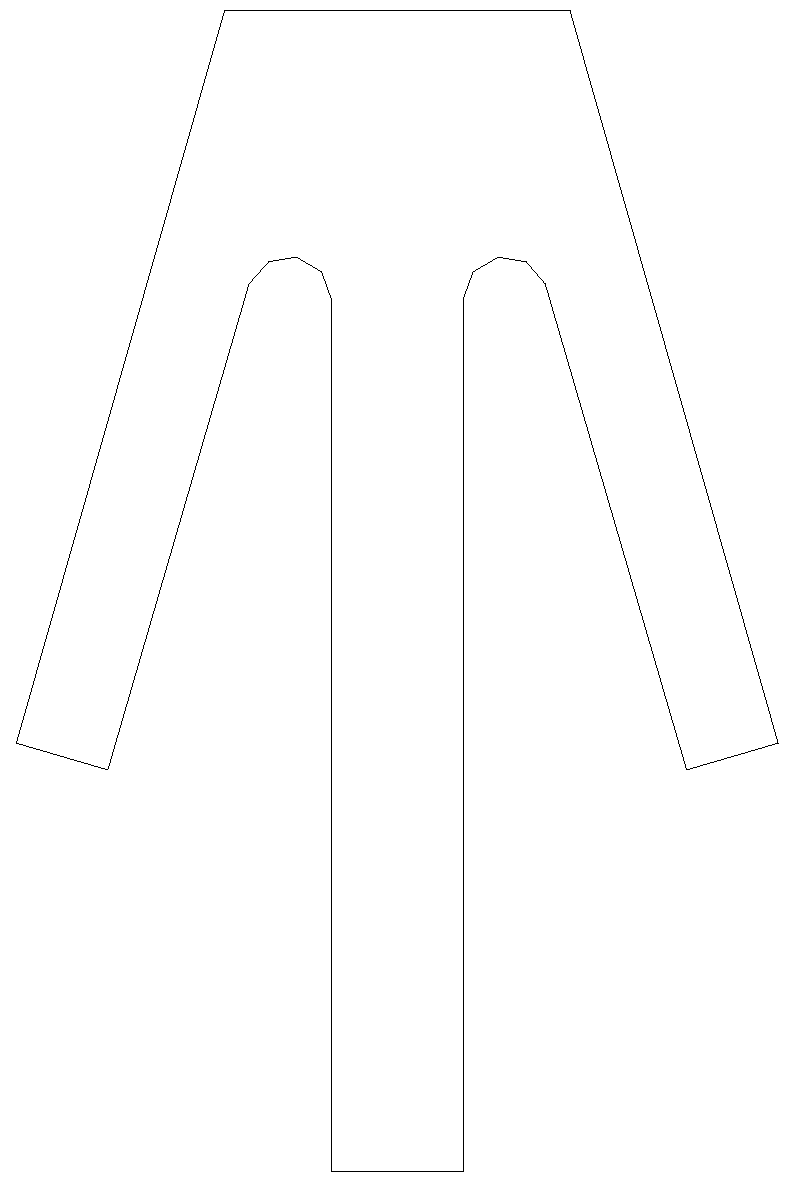

[0038] Specific implementation mode two: refer to image 3 Describe this embodiment in detail. The difference between a resonant quartz tuning fork temperature sensor using special-shaped fork arms described in this embodiment and the resonant quartz tuning fork temperature sensor described in Embodiment 1 is that the two fork arms 32 at the head end The distance between them is smaller than the distance between the ends of the two fork arms 32, and the rest of the structure is exactly the same as that of Embodiment 1.

specific Embodiment approach 3

[0039] Specific implementation mode three: refer to Figure 4 Describe this embodiment in detail. The difference between a resonant quartz tuning fork temperature sensor using special-shaped fork arms described in this embodiment and the resonant quartz tuning fork temperature sensor described in Embodiment 1 is that: the two fork arms of this embodiment 32 and the base portion 33 are located on opposite sides of the connecting portion 31, and the two fork arms 32 are mirror-symmetrically arranged. The working mode of this structure is thickness bending vibration. Different from the traditional quartz tuning fork structure, its two fork arms 32 and base 33 are arranged in two opposite directions, and the length direction of the fork arms is the direction of the mechanical axis of the quartz crystal. The width direction is the electric axis direction of the quartz crystal, and the fork arm thickness direction is the optical axis direction of the quartz crystal.

[0040] There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com