Method for monitoring degree of tightness of bolts of building tower crane based on unmanned aerial vehicle image recognition

An image recognition and unmanned aerial vehicle technology, applied in the testing of mechanical components, testing of machine/structural components, motor vehicles, etc., can solve the problems of long time-consuming manual inspection, increased safety risks, and easy loosening of bolts, etc., to achieve The effect of reducing the probability of human misjudgment, reducing detection time, and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] The height of the tower crane that the embodiment of the present invention chooses is 11.2m, and the width of the tower body is 1.665m, and the height of the single section of the tower crane is 2.8m.

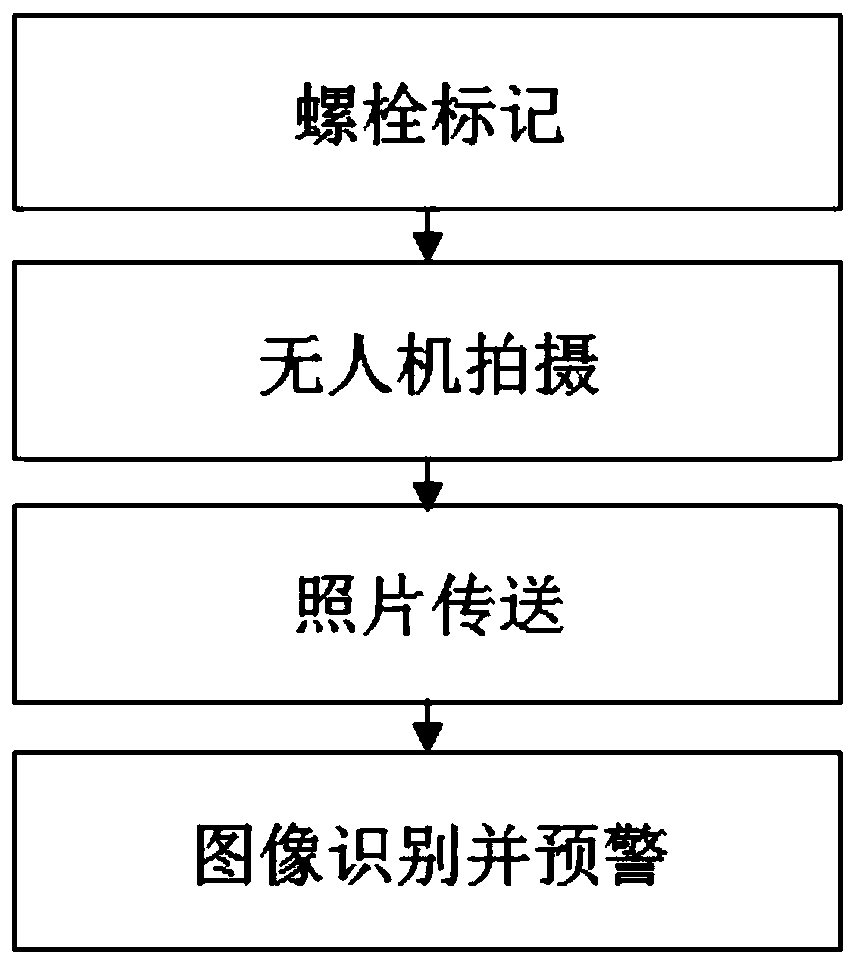

[0031] Such as figure 1 As shown, a method for monitoring the tightness of building tower crane bolts based on UAV image recognition includes steps:

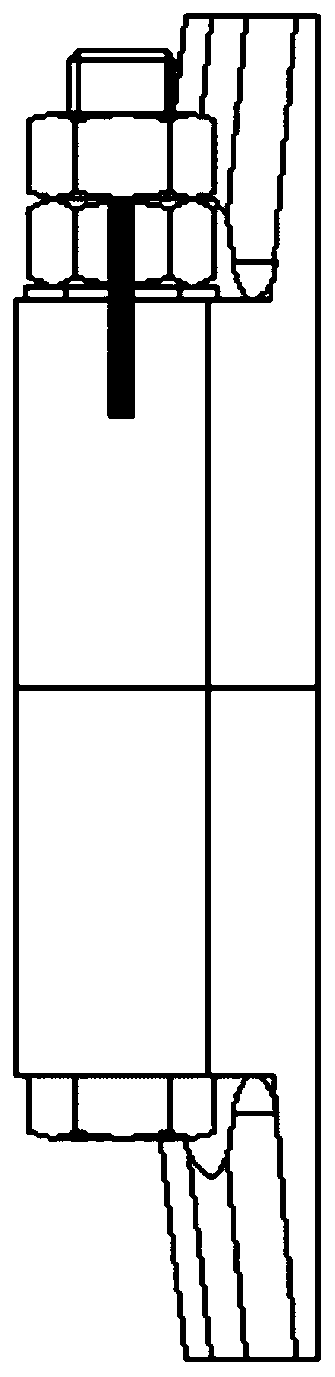

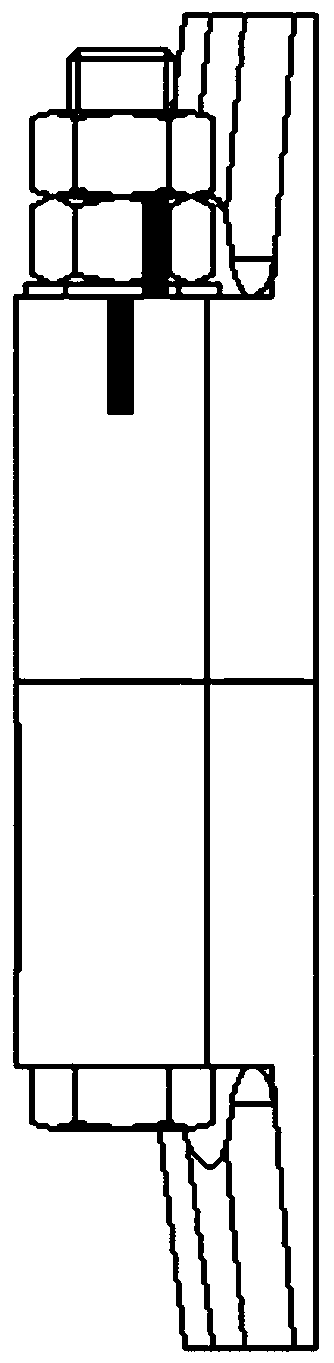

[0032] 1) After the worker tightens each bolt, use a paint pen to make a straight line mark on the surface of the nut and the sleeve in the vertical direction along the outside. The mark spans the outside of the nut and the sleeve and is viewed directly in front of the same horizontal plane as the bolt. When marking, the mark at the nut and the mark at the sleeve are on the same straight line, such as figure 2 As mentioned above, when the bolt is loose, when viewed from the same angle, the part m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com