Ultrahigh-temperature high-frequency material mechanical property testing instrument and method

A technology of high-frequency materials and testing instruments, which is applied in the field of ultra-high-temperature and high-frequency material mechanical performance testing instruments, can solve problems such as long test periods, difficult simulation of extreme environments, and difficult loading of complex loads, so as to shorten fatigue test time and improve accuracy. Effects on Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

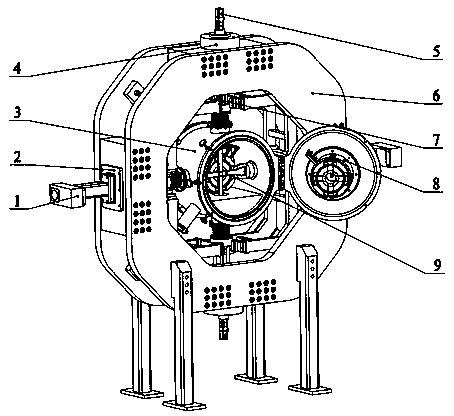

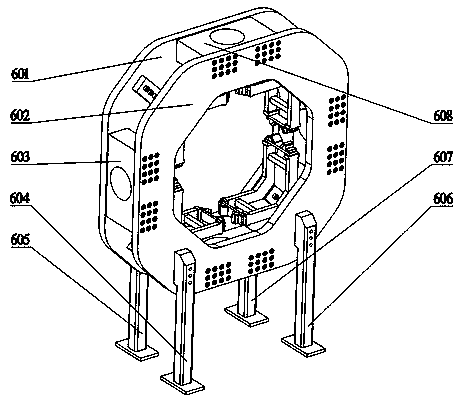

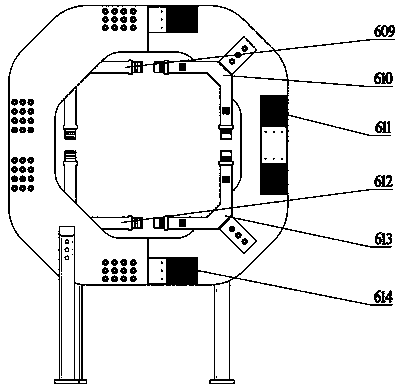

[0054] The tensile / compressive properties of the C / C composites were tested at 1400°C. Before the test, clamp the cross-shaped test piece 9 made of C / C composite material, tighten the front cover 305 of the heating furnace and the rear cover 301 of the heating furnace with the quick tightening mechanism 303, calibrate the instrument, and check the sealing of each module Wait for the preparatory work; start the equipment, first carry out vacuum treatment to the sealed chamber of the heating furnace body 302, and after the vacuum degree reaches the requirement, pass the intermediate frequency current into the intermediate frequency induction heating device 8 to realize the heating of the graphite heating body 806, through the double ratio The color thermometer detects the temperature of the cross-shaped test piece 9, and when the test temperature in the gauge length area reaches 1400°C, the temperature is maintained through the temperature control system; Tensile / compressive tes...

Embodiment 2

[0056] High-frequency fatigue tests were performed on C / C composites at 1400°C. The difference from Example 1 is that after the gauge length area reaches the test temperature of 1400°C, the pre-stretching loading module is controlled to pre-stretch the cross-shaped specimen 9, and the cross-shaped specimen is maintained by the tension / compression loading unit 1. Stretch in the horizontal direction, start the high-frequency fatigue loading module 7 and control the frequency of fatigue loading to 20kHz, carry out high-frequency fatigue testing on the cross-shaped specimen 9, and use digital speckle technology to monitor the testing process through the perspective window of the front cover of the heating furnace. Real-time observation completed the fatigue test of the cross-shaped specimen 9 at a temperature of 1600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com