Same-frequency vibration control method for cross-coupling anti-symmetric magnetic suspension rotor system

A magnetic levitation rotor, cross-coupling technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of scalability and universality limitations, neglect of influence, lack of universality, etc., to achieve applicable Effects of compatibility and extensibility, general applicability and extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

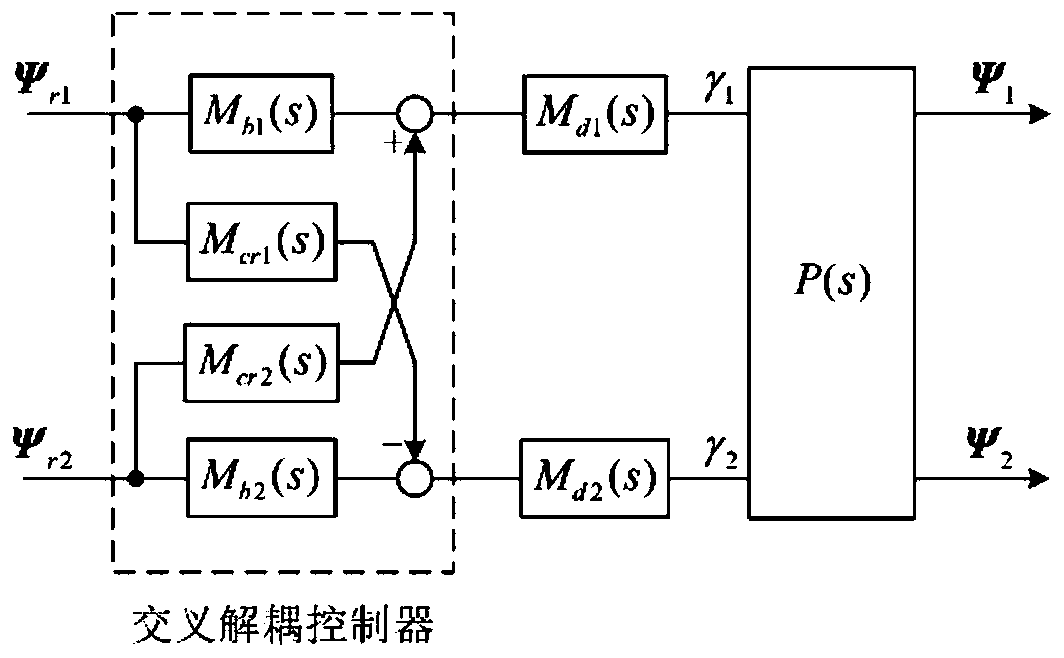

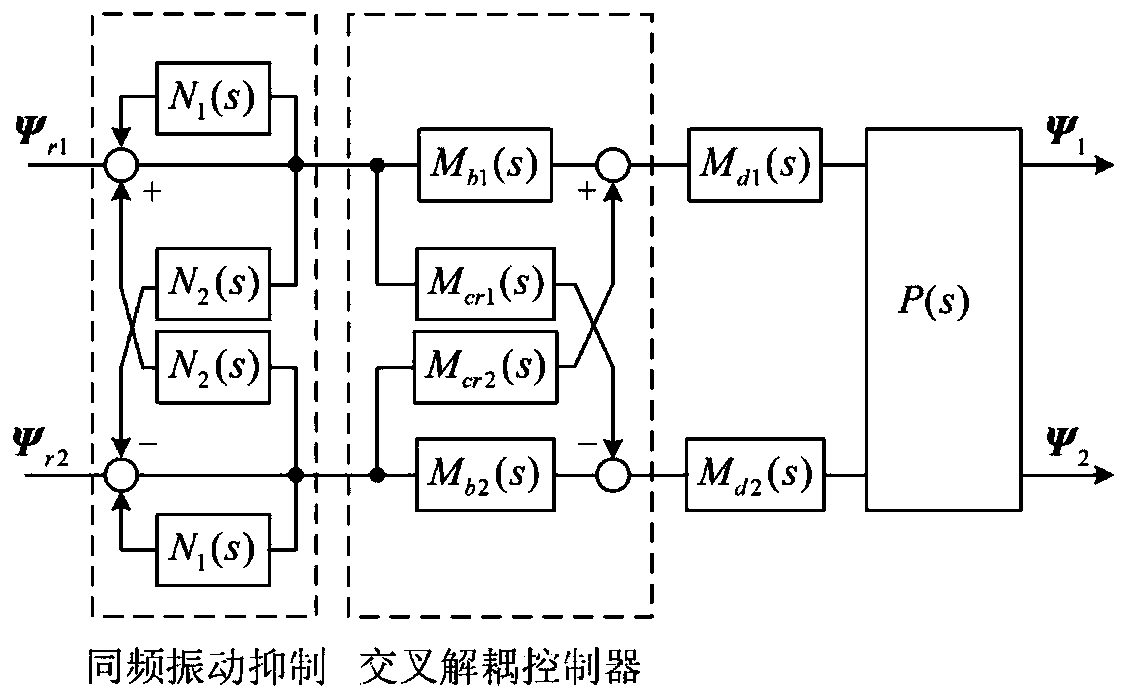

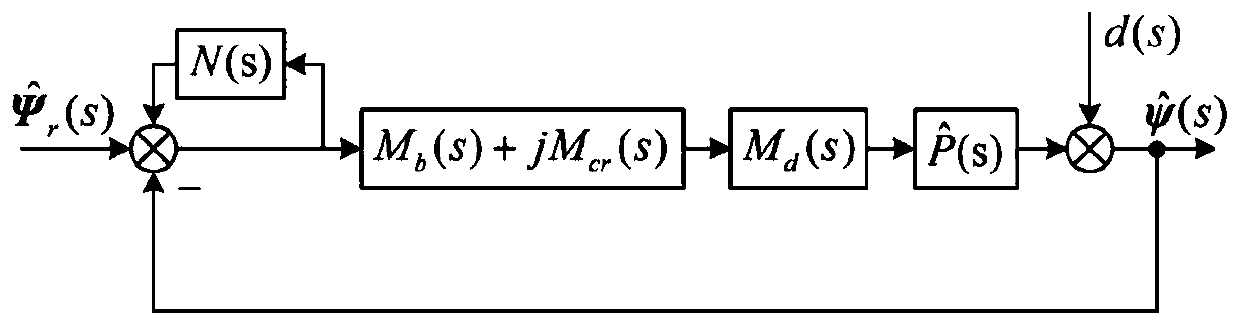

[0046] Attached below Figures 1 to 3 The technical solution of the present invention is described in detail with specific embodiments.

[0047] Step 1. Establish a general formal dynamics model for cross-coupled antisymmetric systems with co-frequency vibrations

[0048] combine figure 1 As shown, P(s) is defined as the control object with cross-coupled anti-symmetric characteristics of vibration at the same frequency, that is, the cross-coupled anti-symmetric maglev rotor system, and its general form can be expressed as:

[0049]

[0050] In the formula, s represents the independent variable in the field of complex numbers, and P d and P cr is an element of the matrix P(s), has no specific meaning, and is only used to describe the manifestation of the cross-coupling antisymmetric characteristic of P(s).

[0051] Suppose ξ=[β α] T is the state variable of the control object P(s), γ=[γ 1 gamma 2 ] T is the input of the control object P(s), Ψ=[Ψ 1 Ψ 2 ] T As the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com