Substrate defect inspection apparatus, substrate defect inspection method and storage medium

A defect inspection and substrate technology, applied in measuring devices, image data processing, instruments, etc., can solve problems such as insufficient learning

- Summary

- Abstract

- Description

- Claims

- Application Information

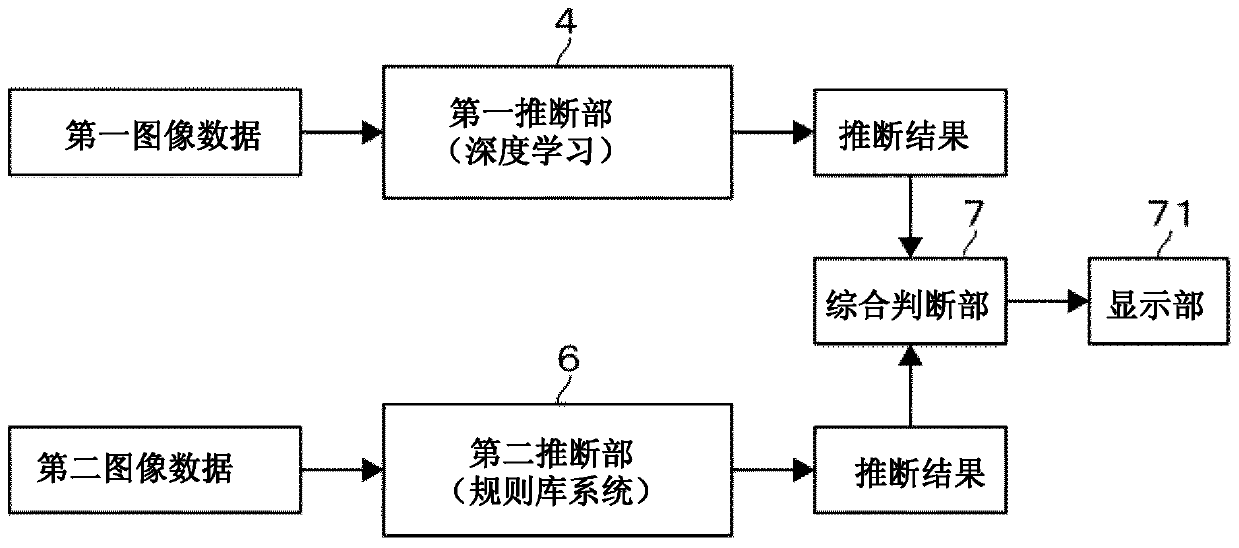

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

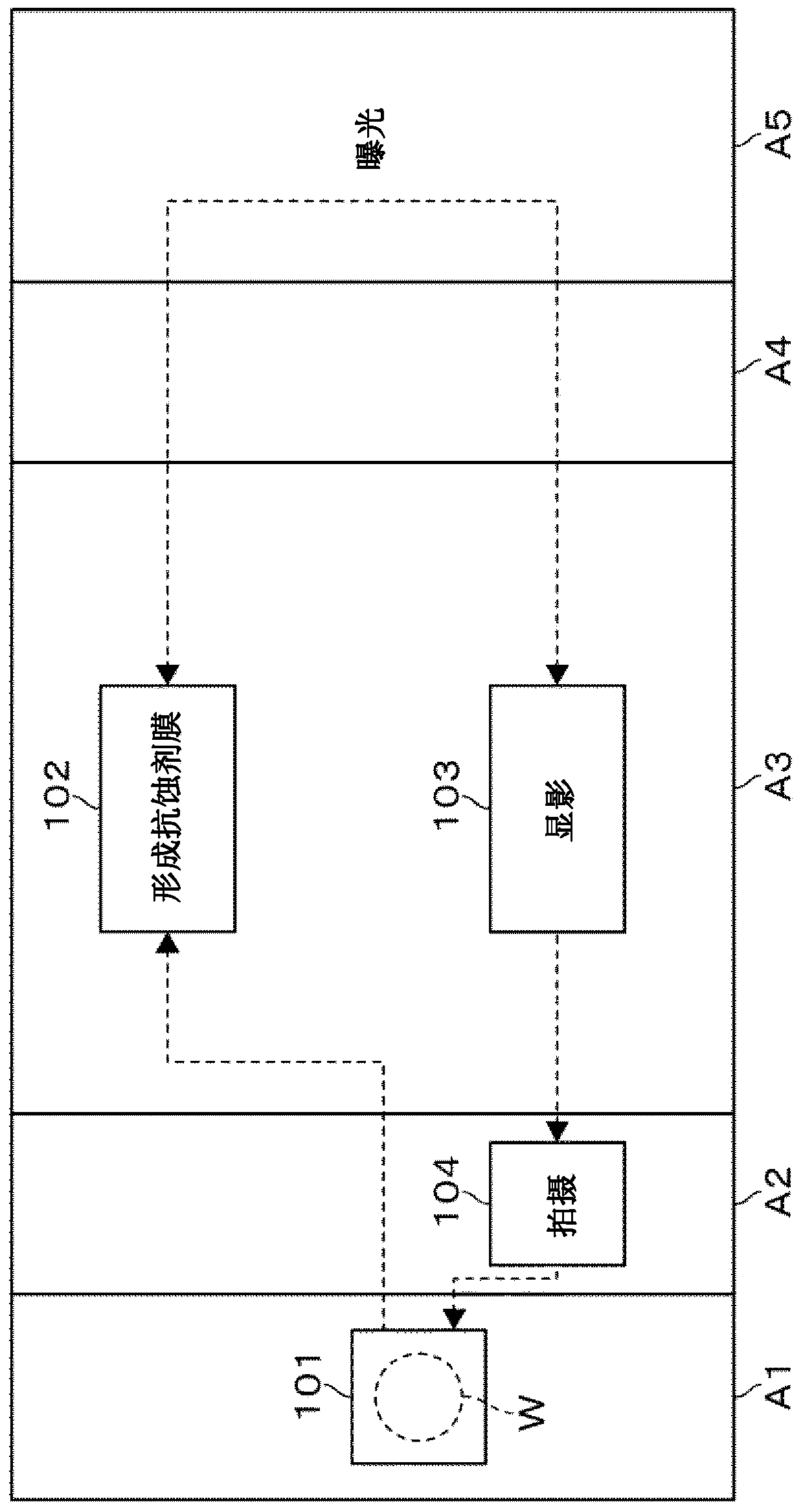

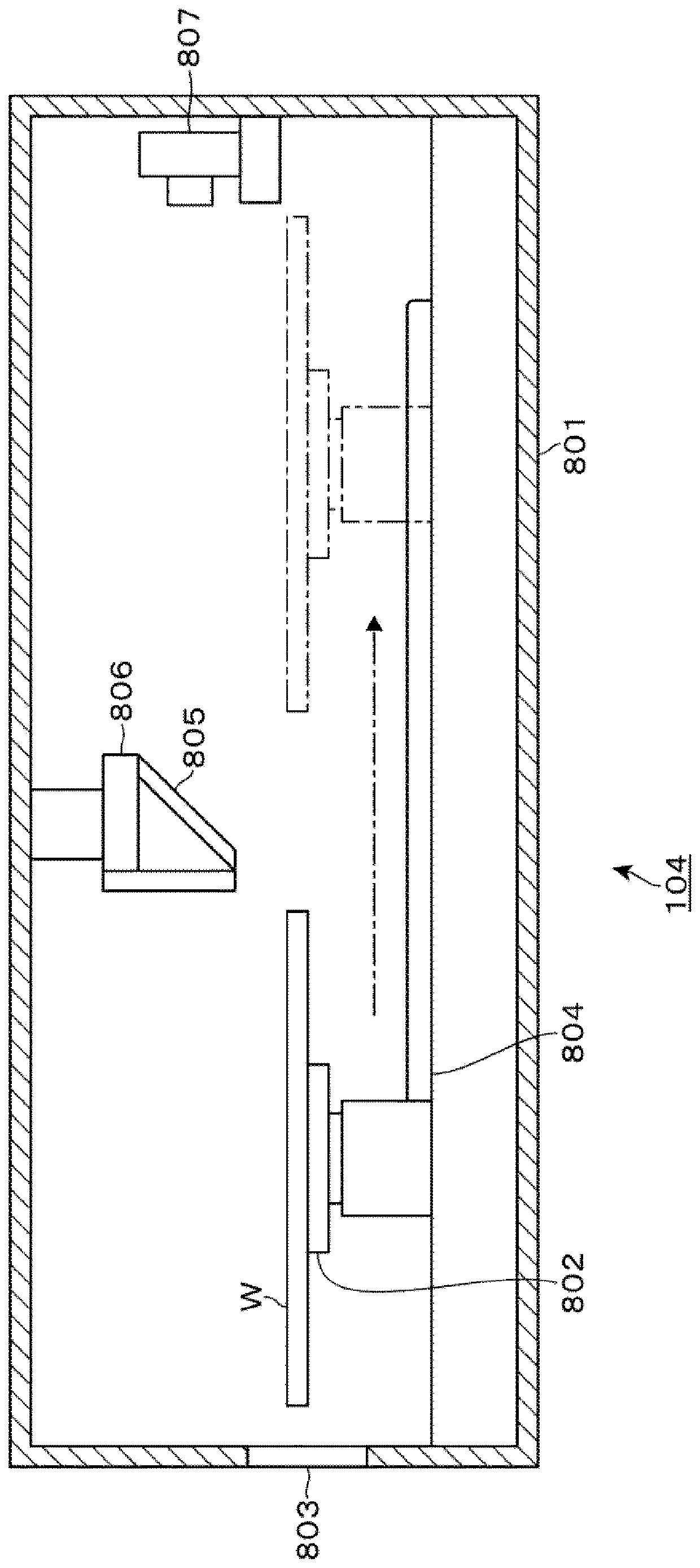

[0057] The substrate defect inspection apparatus of the present invention performs defect inspection based on, for example, an image of a wafer captured by a camera module that can be applied to a coating and developing device that performs resist coating and post-exposure development, and Set in the coating and developing device.

[0058] First, refer to the figure 1, an example of a coating and developing device will be described. The coating and developing device is configured such that the carrier block A1 , the intermediate block A2 , the process block A3 , and the interface block A4 are sequentially connected linearly in the horizontal direction. The interface block A4 is connected with the exposer A5. The carrier 101 containing the wafer W which is a substrate is transported by a carrier transport mechanism not shown and placed on the carrier block A1. The processing block A3 is provided with: a coating module 102 for supplying a resist to the surface of the wafer W ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com