Edge alignment method

An edge alignment and edge technology, which is applied to machine tools, image data processing, and stone processing equipment suitable for grinding the edge of workpieces, can solve the problem of cutting area offset and the inability to properly estimate the position of the edge of the workpiece, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

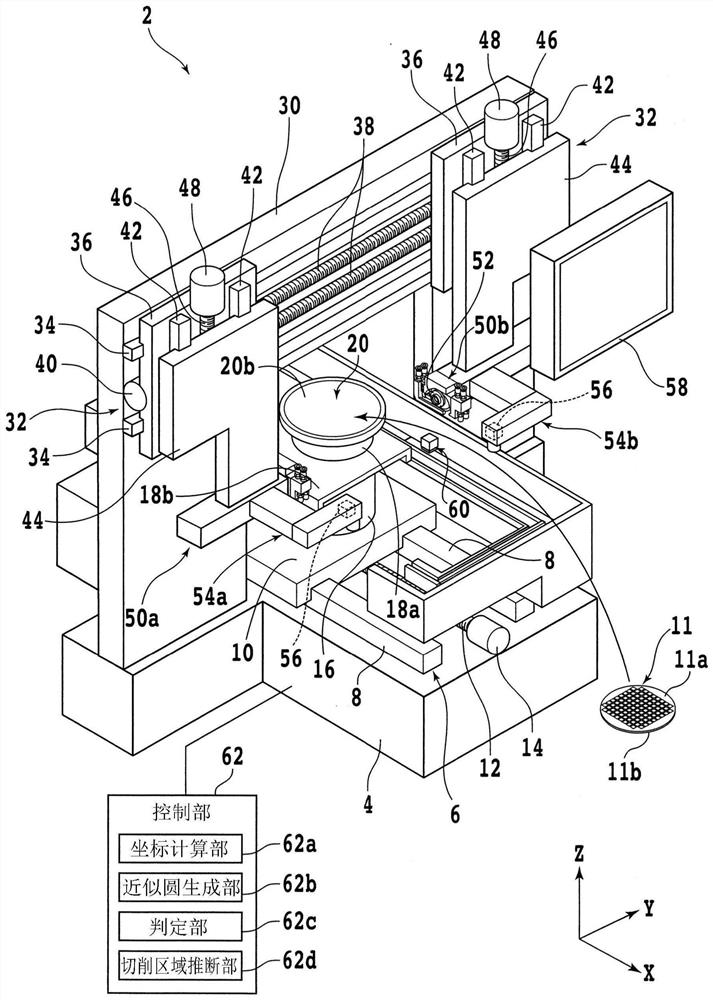

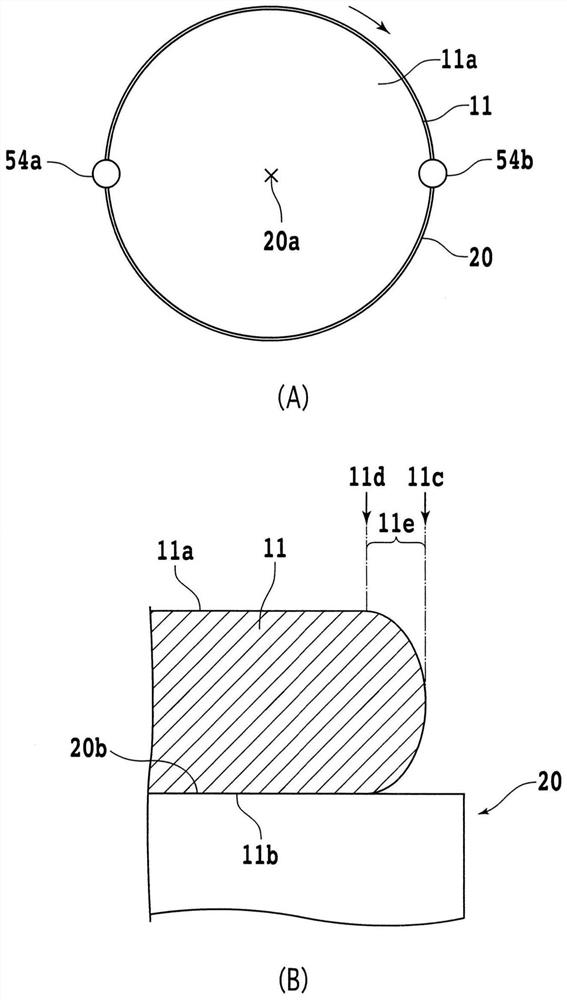

[0023] An embodiment of one embodiment of the present invention will be described with reference to the drawings. figure 1 It is a perspective view of the cutting device 2 . figure 1 The shown X-axis direction (machining feed direction, front-rear direction), Y-axis direction (index feed direction), and Z-axis direction (vertical direction, height direction) are perpendicular to each other.

[0024] In addition, in figure 1 In , a function block is used to represent a part of a constituent element. The cutting device 2 has a base 4 on which each component is mounted. An X-axis moving mechanism 6 is provided on the upper surface of the base 4 . The X-axis moving mechanism 6 has a pair of X-axis guide rails 8 substantially parallel to the X-axis direction.

[0025] An X-axis movable table 10 is slidably attached to the X-axis guide rail 8 . A nut (not shown) is attached to the lower surface (rear surface) side of the X-axis movable table 10, and the X-axis ball screw 12 sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com