Heat dissipation device of electronic component

A technology for electronic components and heat dissipation devices, applied in the field of heat dissipation devices for electronic components, can solve the problems of large volume of heat dissipation devices, low heat dissipation speed and heat dissipation efficiency of heat dissipation devices, and achieves convenient fixed connection, improved speed and heat dissipation efficiency. , the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

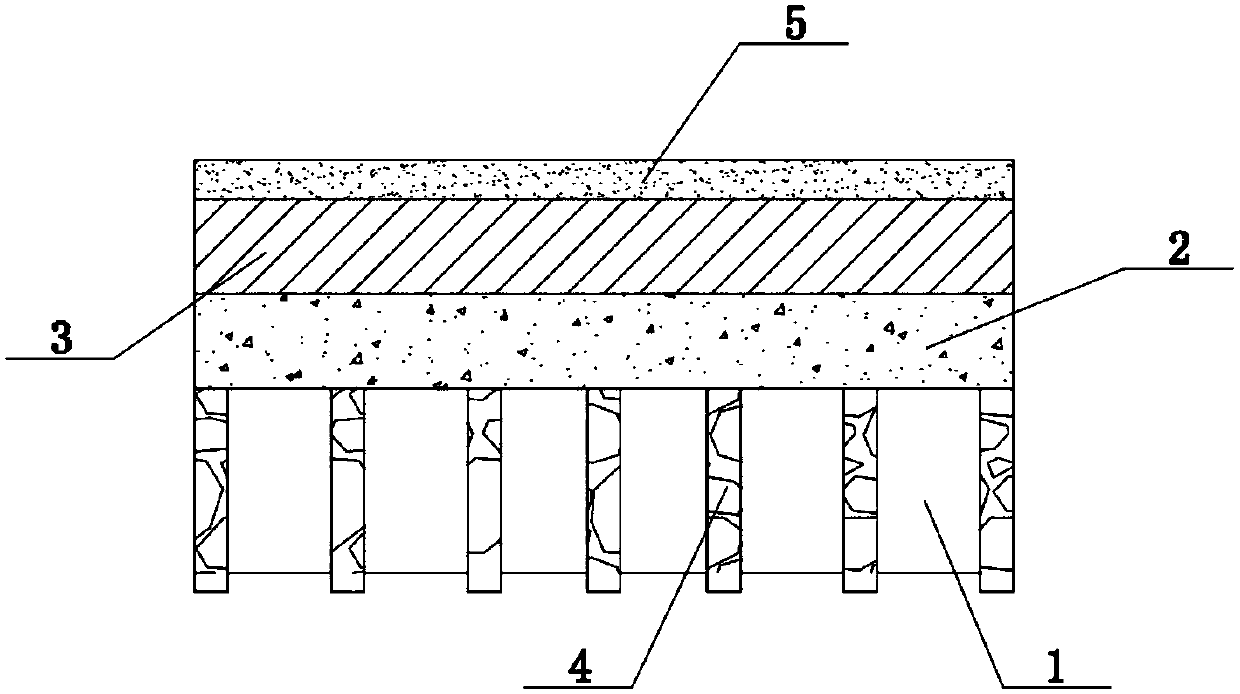

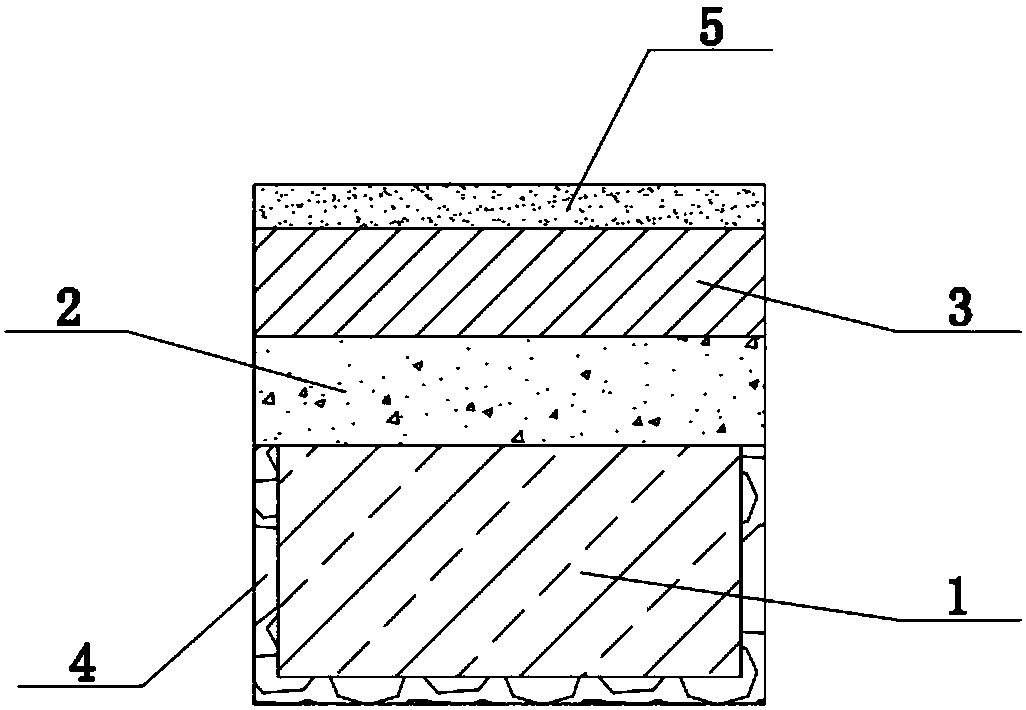

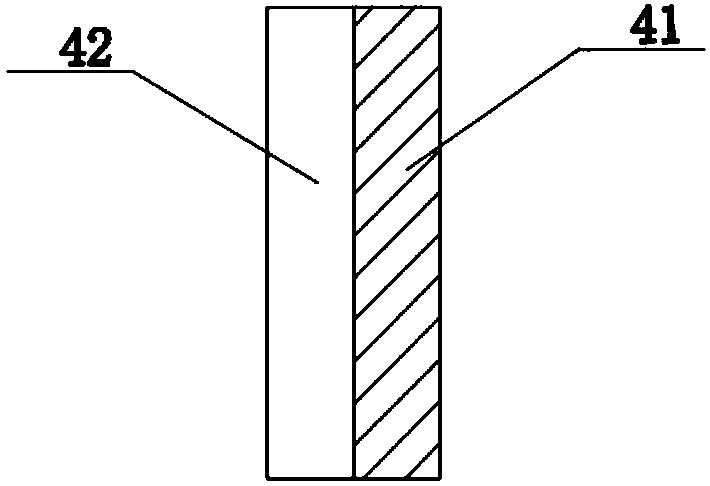

[0021] see Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: it includes a heat source body 1, a heat conduction layer 2, a heat dissipation layer 3, and an elastic heat conduction layer 4, the upper surface of the heat source body 1 is bonded to the heat conduction layer 2, and the heat dissipation The layer 3 is located above the heat conduction layer 2 and bonded to the heat conduction layer 2. The elastic heat conduction layer 4 is arranged under the heat conduction layer 2. The elastic heat conduction layer 4 is a ring-shaped elastic connector structure and is bonded to the heat source body 1. connected, and the heat source body 1 is fixedly connected to the heat conduction layer 2 through the elastic heat conduction layer 4, the elastic heat conduction layer 4 includes a graphene layer 41 and an elastic connector 42, and the graphene layer 41 is arranged on the surface of the elastic connector 42.

[0022] It also includes a func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com