Cigarette annular punching device based on cut tobacco density

A punching device and density technology, which is applied to measuring devices, tobacco, cigarette manufacturing, etc., can solve the problems of affecting the quality of cigarettes, blowing out, inaccurate pressure, etc., and achieve the effect of avoiding the quality of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

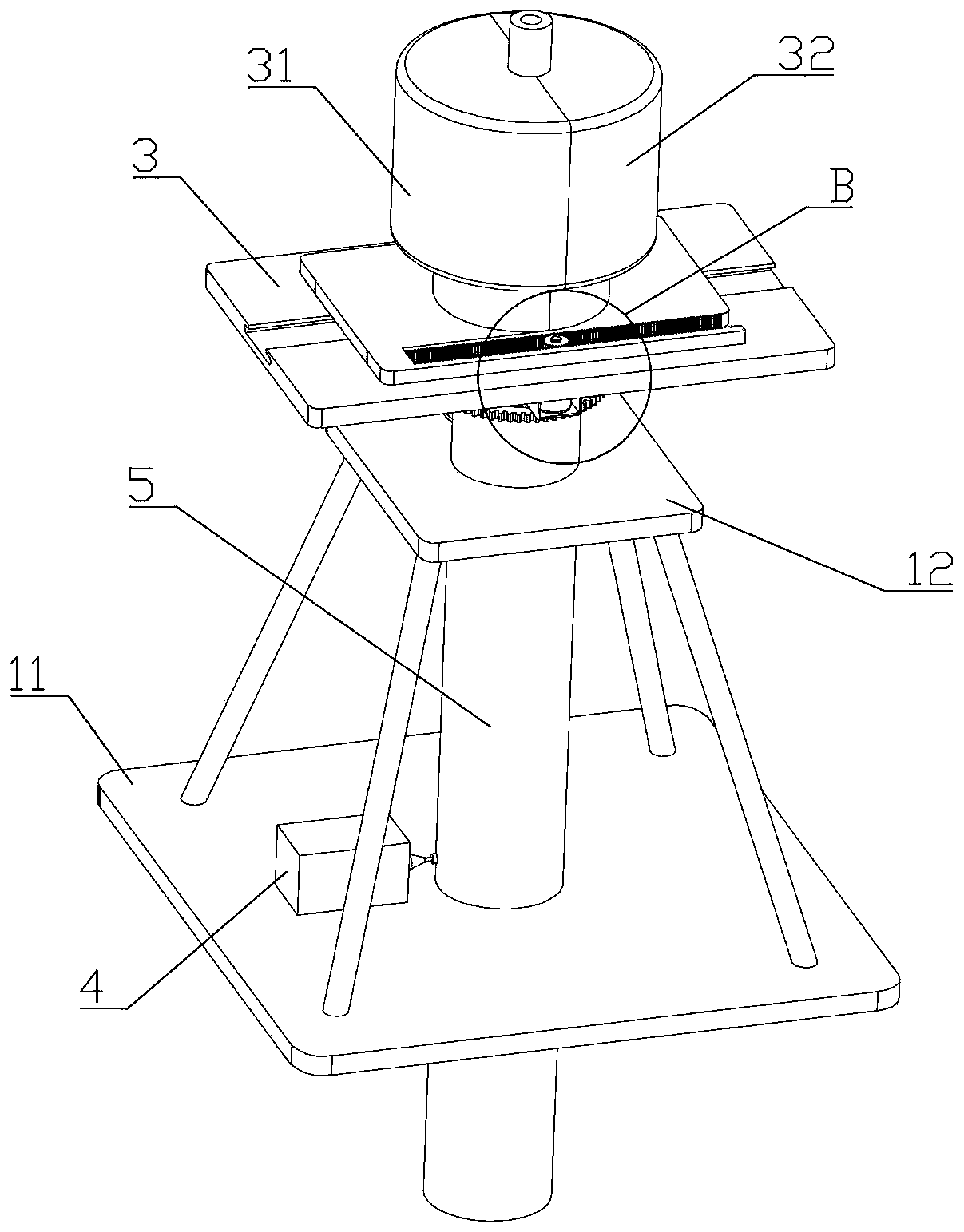

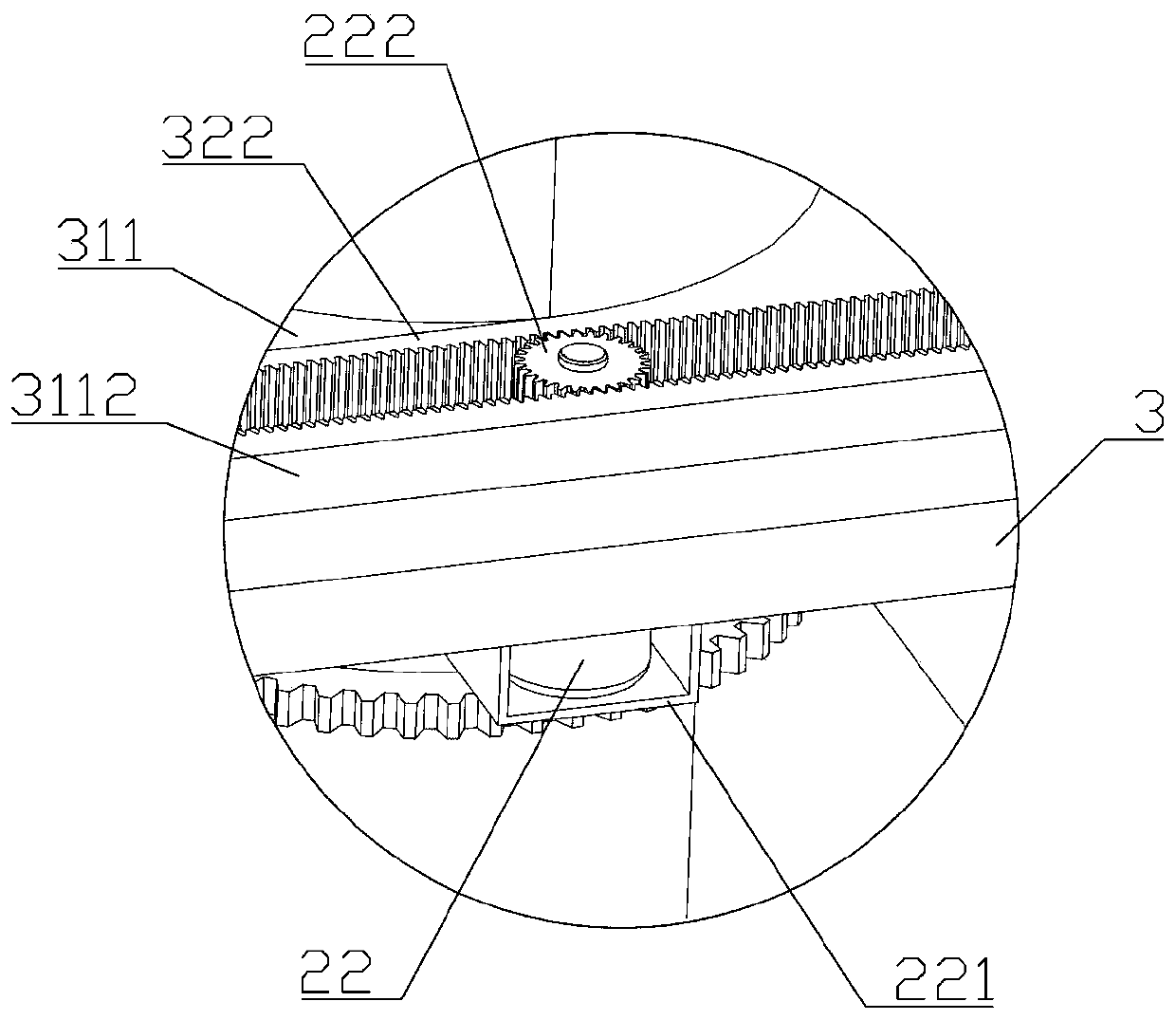

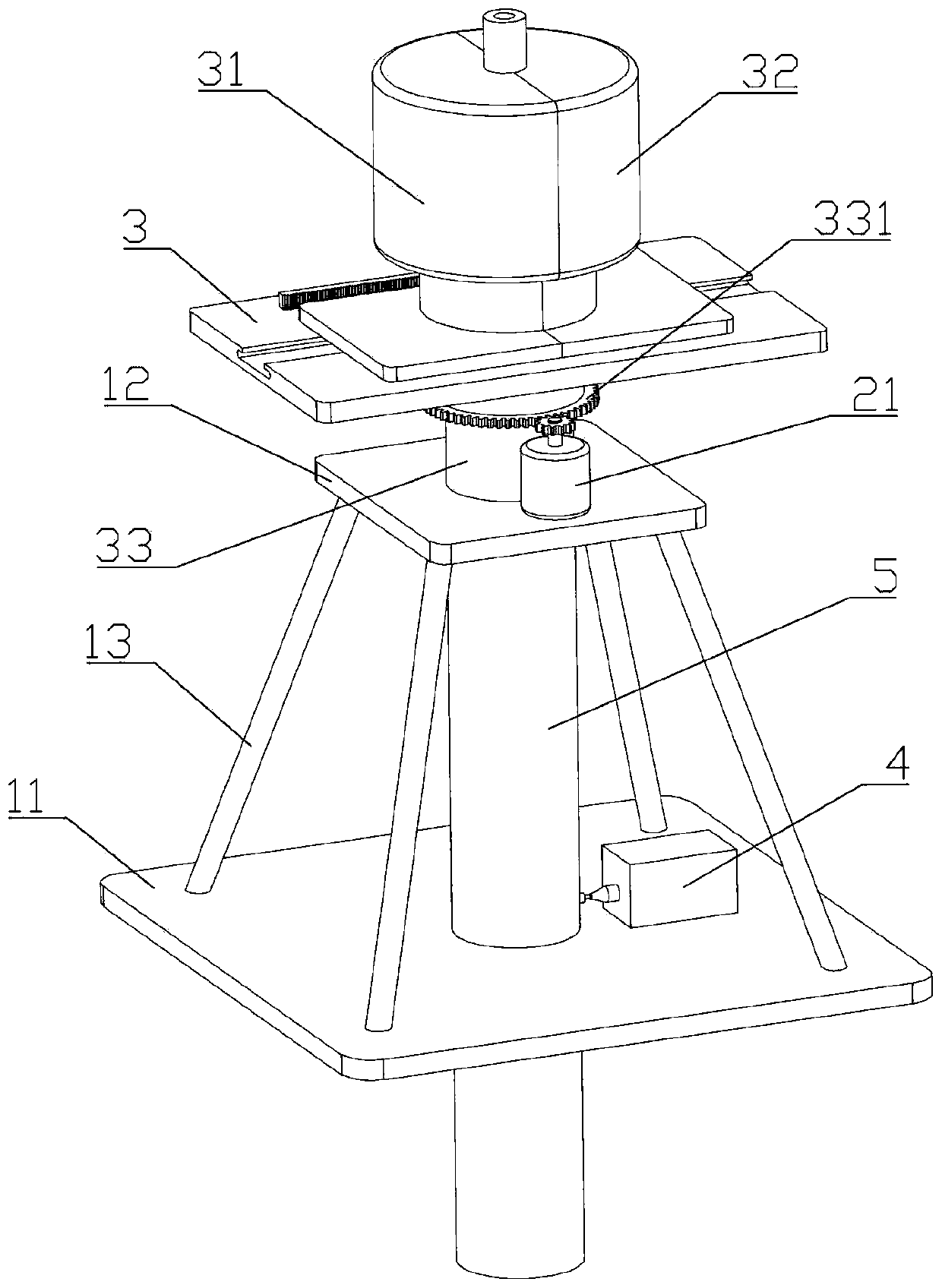

[0036] like Figure 1-9As shown, it includes a mounting frame, an industrial computer, a detection cylinder 5 and a laser puncher 4. The laser head of the laser puncher 4 passes through the cylinder wall on the first detection cylinder 5 and the laser output end of the laser head is located at the first detection cylinder 5. The inside of a detection tube 5, the laser puncher 4 and the detection tube 5 are installed on the mounting frame, the input end of the laser puncher 4 is connected with the output end of the industrial computer, and the detection tube 5 is used to place cigarettes 9, A cigarette holder clamping mechanism is rotatably installed on the detection cylinder 5, and the cigarette holder clamping mechanism includes a bottom plate 3 and a first clamping piece 31 and a second clamping piece 32 that are slidably mounted on the bottom plate 3, and the first clamping piece 31 and the second clamping piece 32 are slidingly mounted on the bottom plate 3. The second cla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap