Cooking utensil for steam heating and steam cooker

A technology of cooking utensils and steam, which is applied in the direction of steam cooking utensils, cooking utensil lids, cooking utensils, etc. It can solve the problems of poor heating effect, uneven heating of rice, affecting the taste of rice, etc., and achieve the effect of increasing thermal efficiency and improving cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

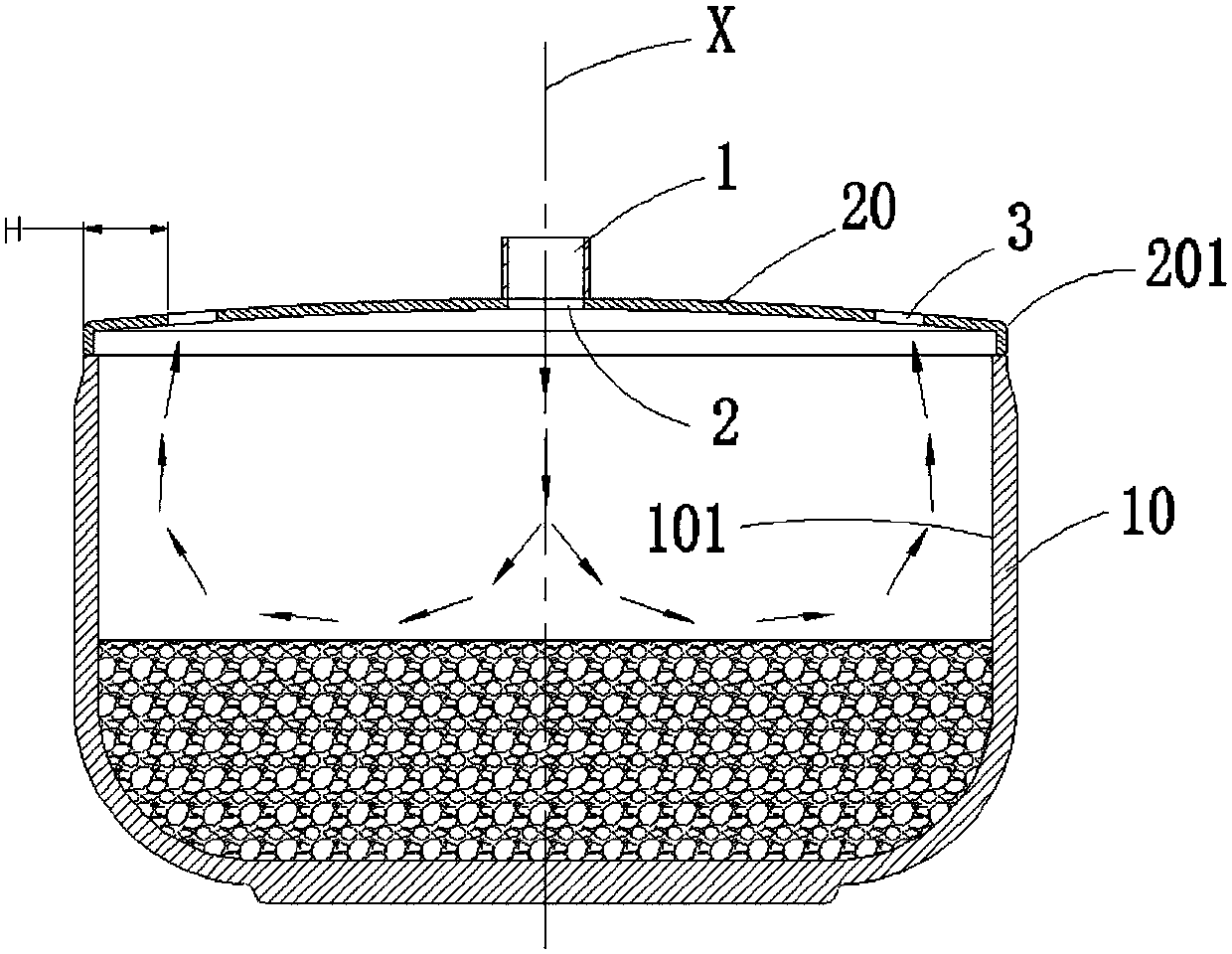

[0030] See Figure 1 to Figure 2 , which is a diagram of Embodiment 1 of a cooking appliance for steam heating according to the present invention.

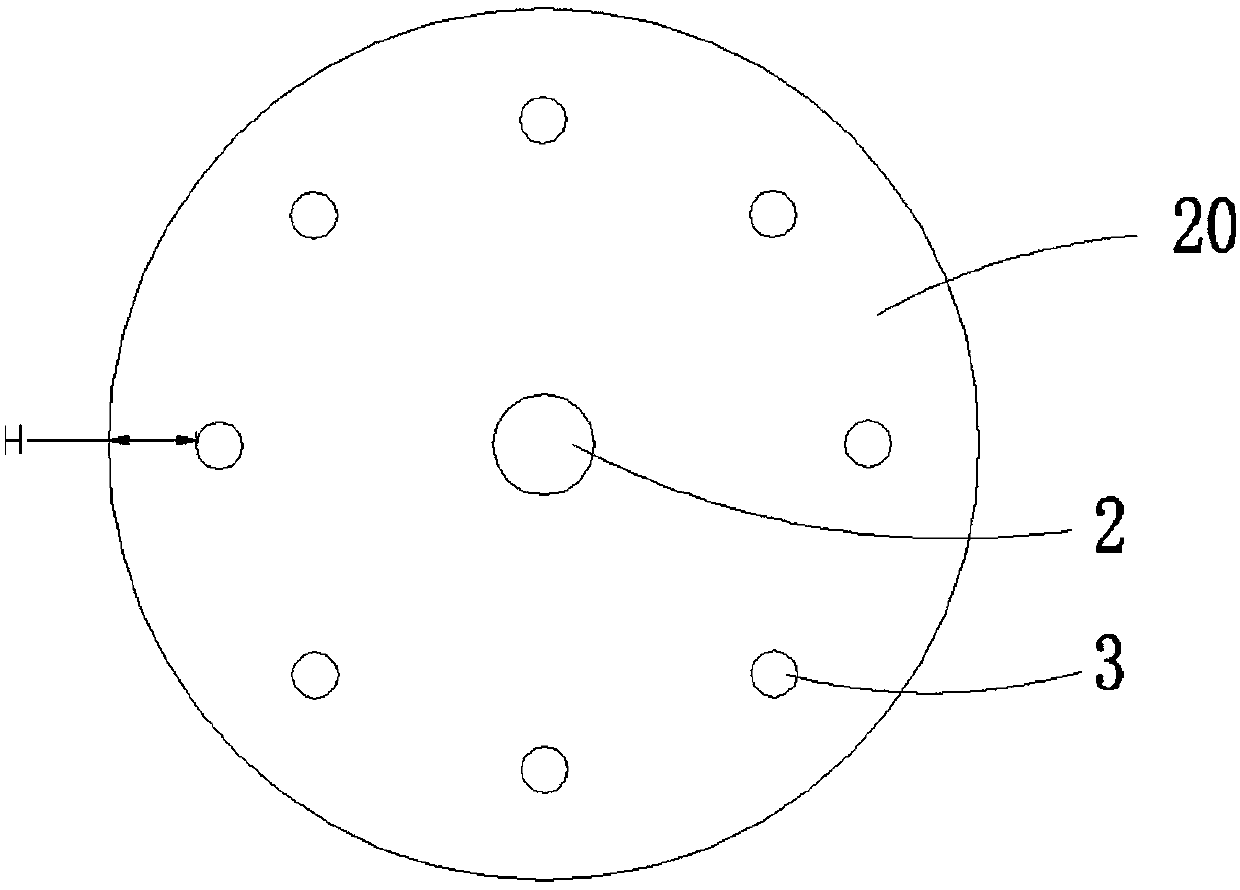

[0031] A cooking utensil for steam heating, comprising a pot body 10 and a pot cover 20 covering the pot body 10, the pot cover 20 is provided with an air inlet channel 1 leading into the pot body 10 from above the pot body 10 And the steam inlet 2 that communicates with the air inlet channel 1, and the steam outlet 3, the steam outlet 3 is located at the position near the edge 201 of the pot cover and is far away from the steam inlet 2, and then refer to figure 2 As shown, there are multiple steam outlets 3 , and each steam outlet 3 is arranged around the steam inlet 2 .

[0032] The pot body 10 is filled with food, and steam is provided to the pot body 10 through the air inlet channel 1, and then the steam enters the pot body 10 from the steam inlet port 2 to realize steam heating, and the excess steam is discharged from the s...

Embodiment 2

[0043] see Figure 3-4 , which is a diagram of Embodiment 2 of a cooking appliance for steam heating in the present invention. The difference from Embodiment 1 is that a unified air outlet channel 4 is also provided, as follows.

[0044] refer to Figure 4 As shown, the pot cover 20 is provided with an air outlet channel 4 , and an internal channel 5 that communicates the air outlet channel 4 with each of the steam outlets 3 is arranged in the pot cover 20 . The steam discharged from each steam outlet 3 is gathered through the unified air outlet channel 4 and then discharged together to avoid direct discharge of steam from the position of each steam outlet 3, and the steam is exported to a designated position through the outlet channel 4.

[0045] For example, the air outlet channel 4 can discharge the steam from a position that does not affect the user, such as concentrated discharge upward, or discharge toward the rear, so as to prevent the steam from being discharged from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap