Multistage composite filtering type welding fume purification system

A technology of welding fume purification and composite filtration, which is applied in combination devices, chemical instruments and methods, gas treatment, etc., can solve the problems of reduced exhaust air volume, large volume, poor exhaust air effect, etc., and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

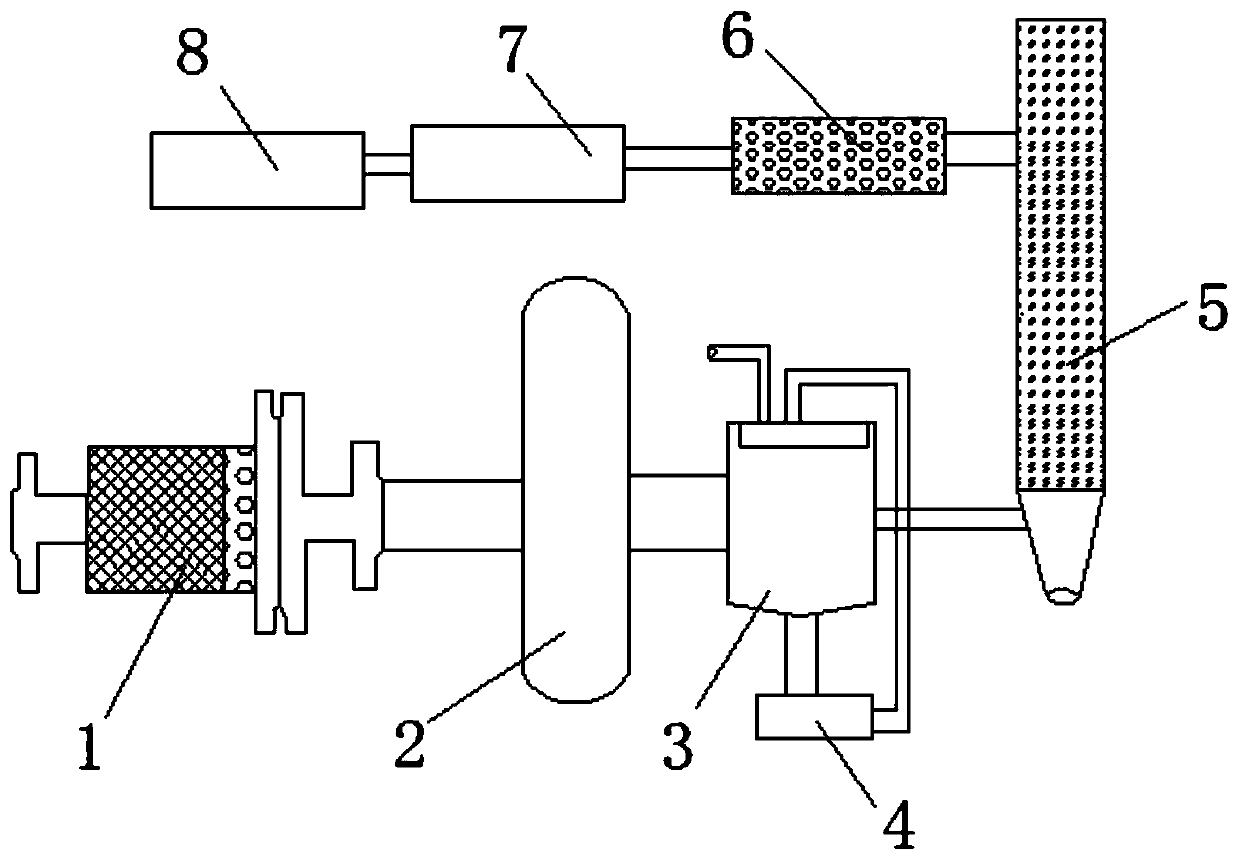

[0016] The invention provides a multi-stage composite filter type welding fume purification system, such as figure 1 As shown, it includes sequentially connecting flame arrester 1, primary filter 2, spray impurity remover 3, electrostatic precipitator 4, intermediate filter 6, TiO 2 Photocatalyst purifier 7 and negative ion generator 8. Among them, the flame arrester 1 is a ZHQ-S gravel flame arrester, and the primary filter 2 is a disc primary filter.

[0017] Among them, the air outlet of the flame arrester 1 is connected with the air inlet of the primary effect filter 2, the air outlet of the primary effect filter 2 is connected with the air inlet of the spray impurity remover 3, and the air outlet of the spray impurity remover 3 is connected with the electrostatic precipitator The air inlet of the device 5 is connected, the air outlet o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap