Uniform-temperature rapid temperature change test box

A test box, fast technology, applied in the field of test box, can solve unreasonable problems such as economy, environmental protection and energy saving, and achieve the effect of compact structure, easy control and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

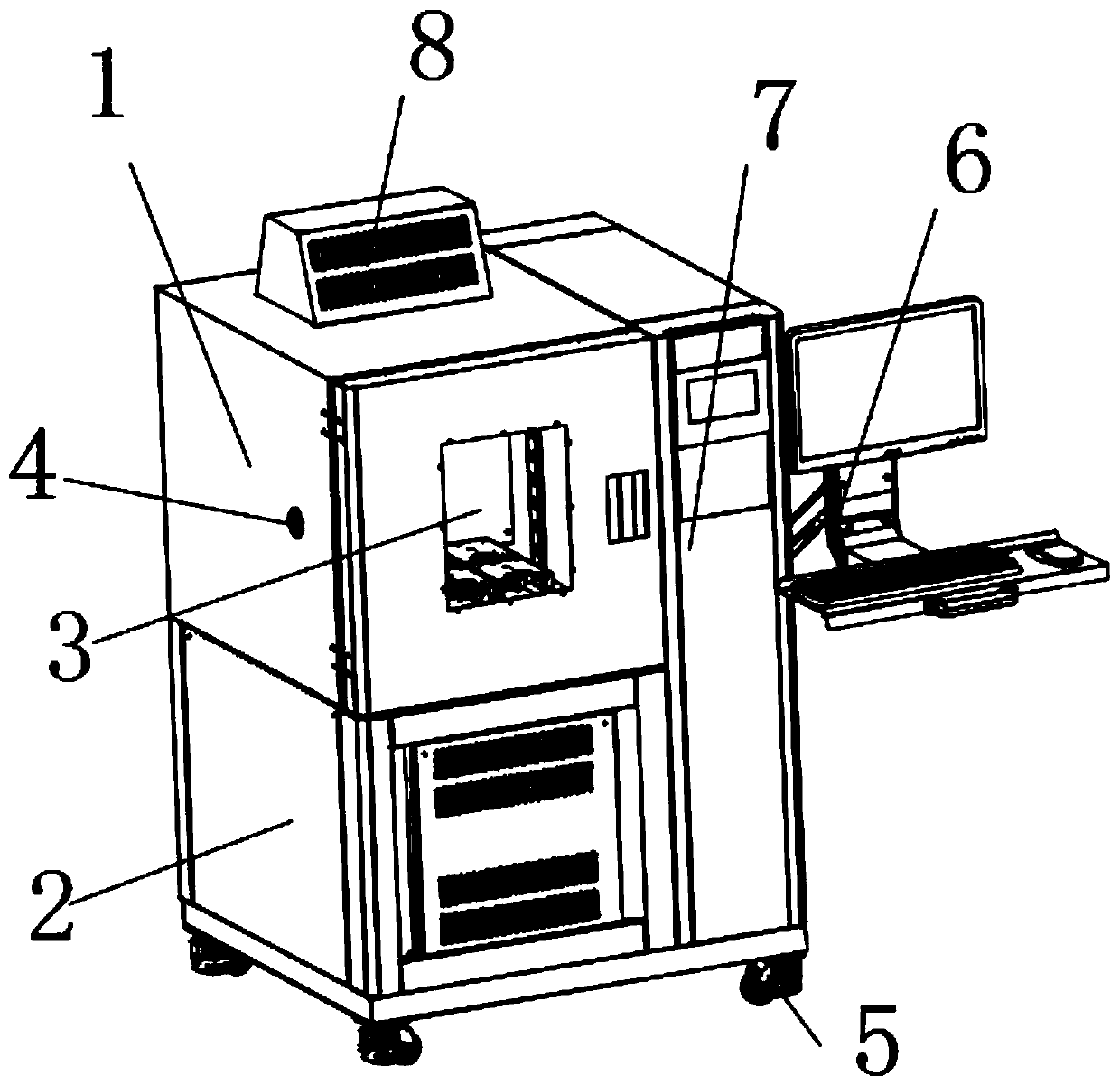

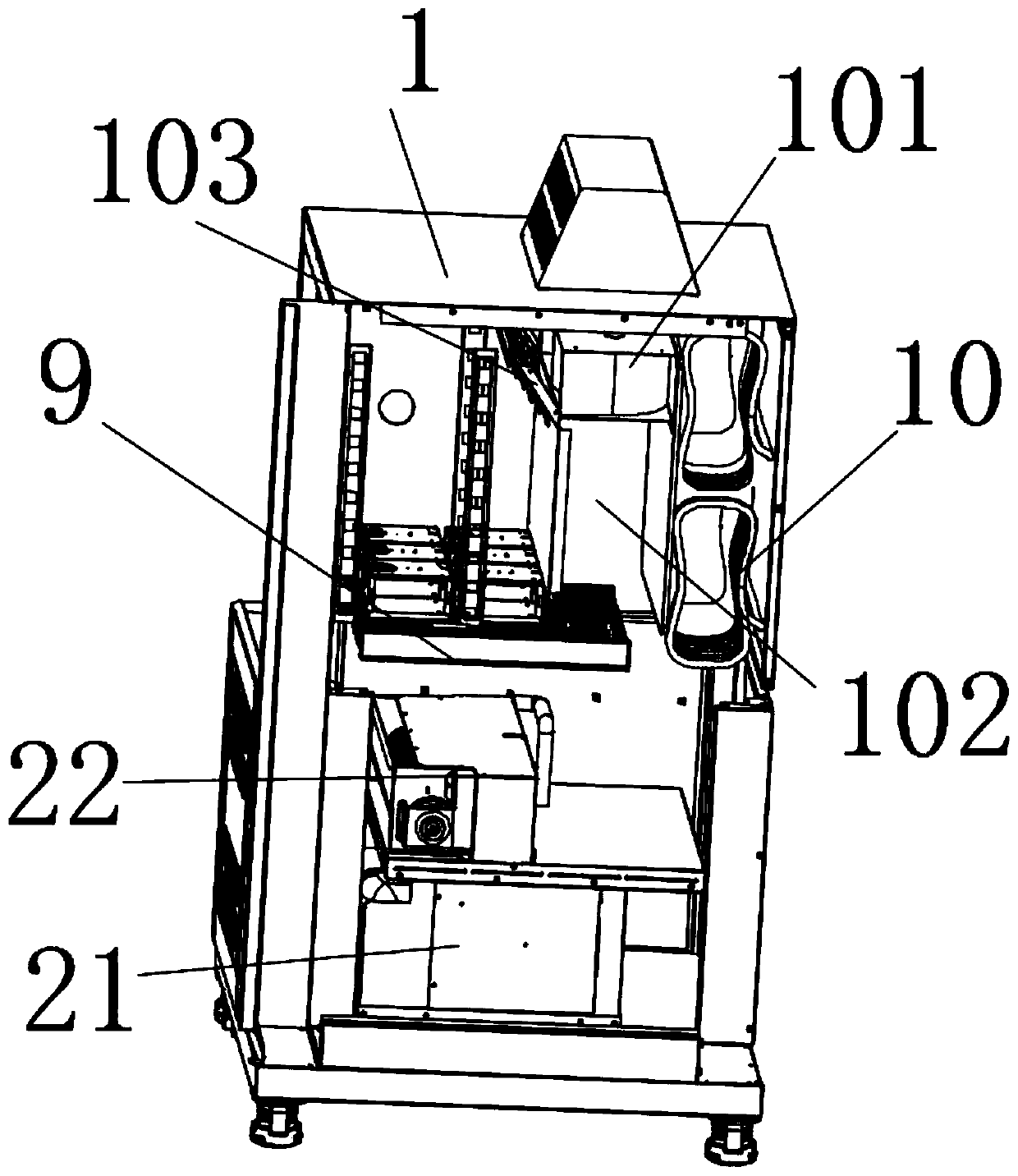

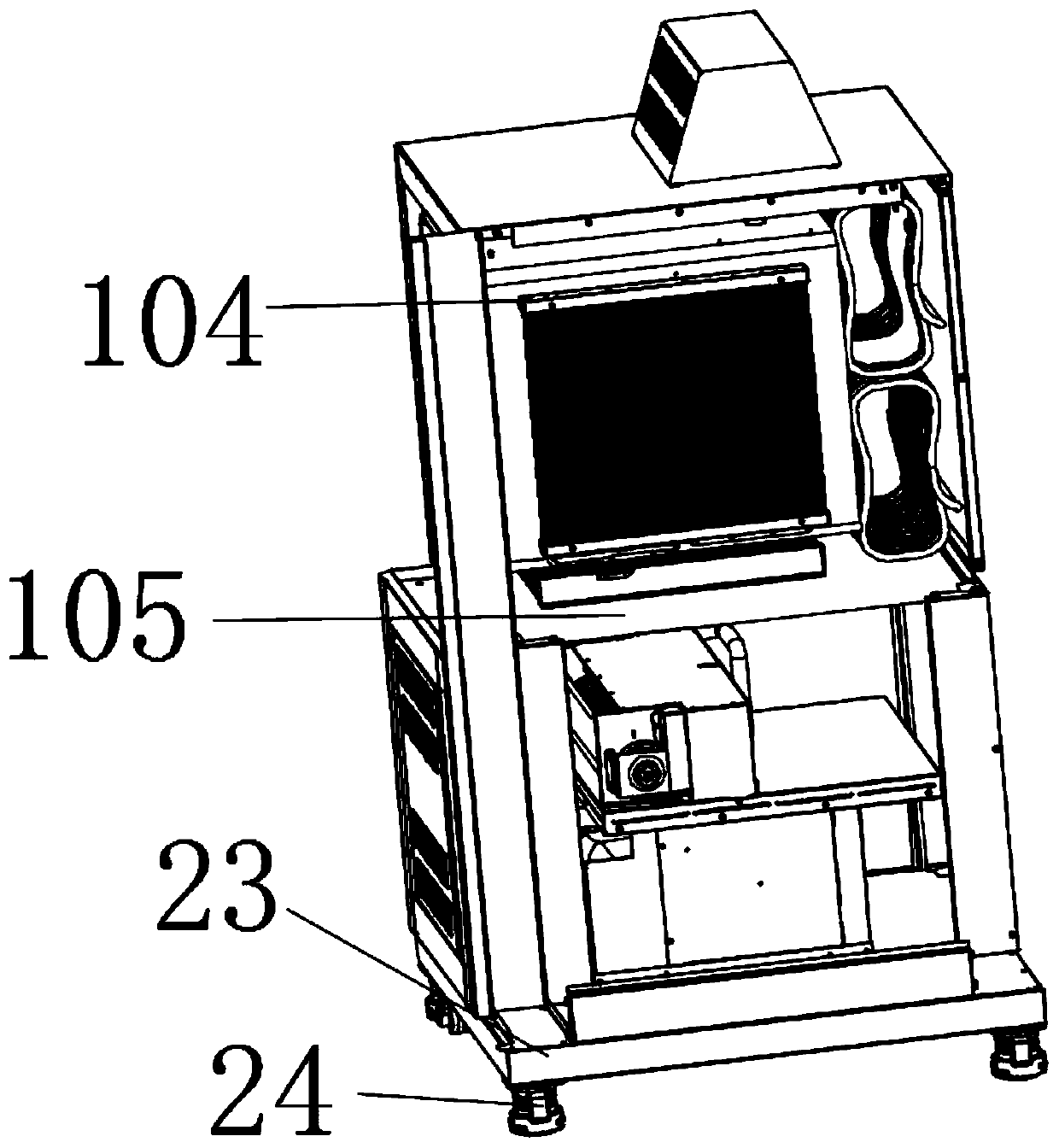

[0023] Example: isothermal rapid temperature change test chamber, as attached Figure 1-5 As shown, it includes a test area 1 and an energy storage area 2; an observation window 3 is opened outside the test area 1, and the test area 1 and the energy storage area 2 are isolated from each other, and the test area 1 is fixedly installed in the energy storage area 2, the connection between the test area 1 and the energy storage area 2 is sealed and connected through the isolation plate 105. Such as image 3 shown.

[0024] An air compressor is fixedly installed in the test area, and dry air is input into the air compressor. The output end of the air compressor is in the test area, and the compressed air source entering the test chamber should be kept above 2kg. The air compressor is reasonably combined with the cooling and heating components inside the test chamber, and the rate of temperature change is adjusted by the speed of compressed air flow.

[0025] A test chamber 100 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap