High-yield grain winnowing machine

A technology for air separators and grains, which is applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of poor cleaning effect and low yield, etc. Good conditions and the effect of preventing material clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038] Example 1

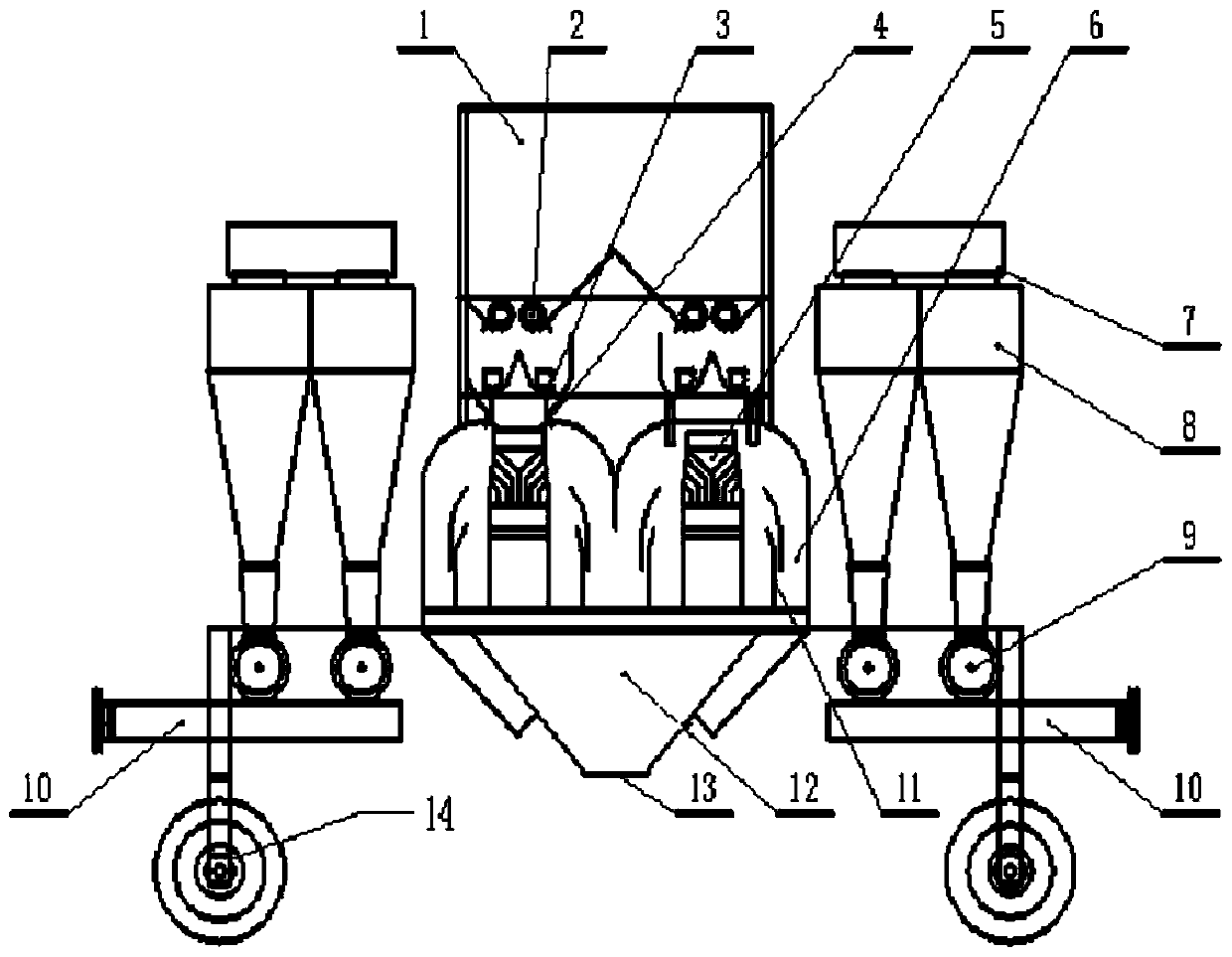

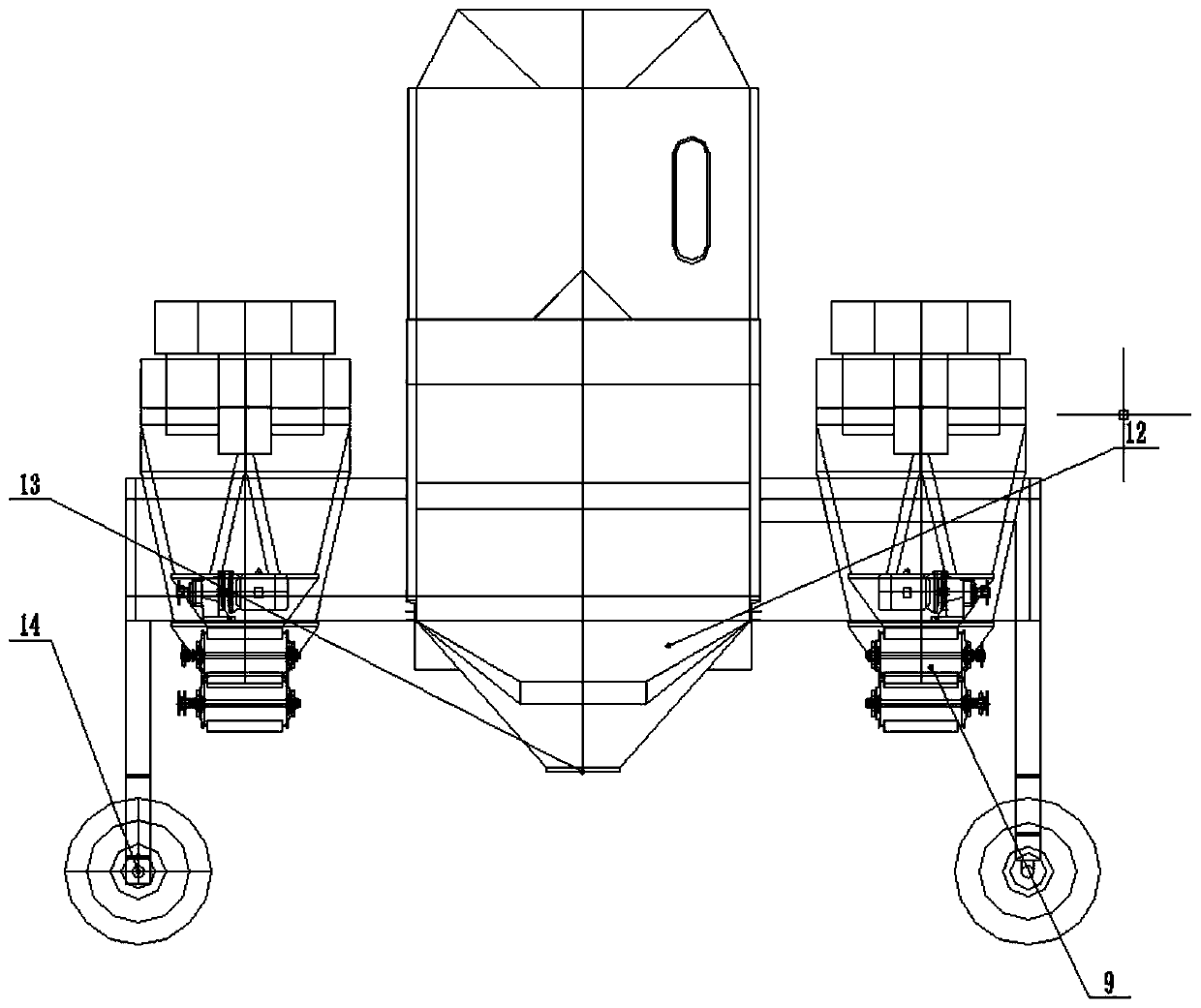

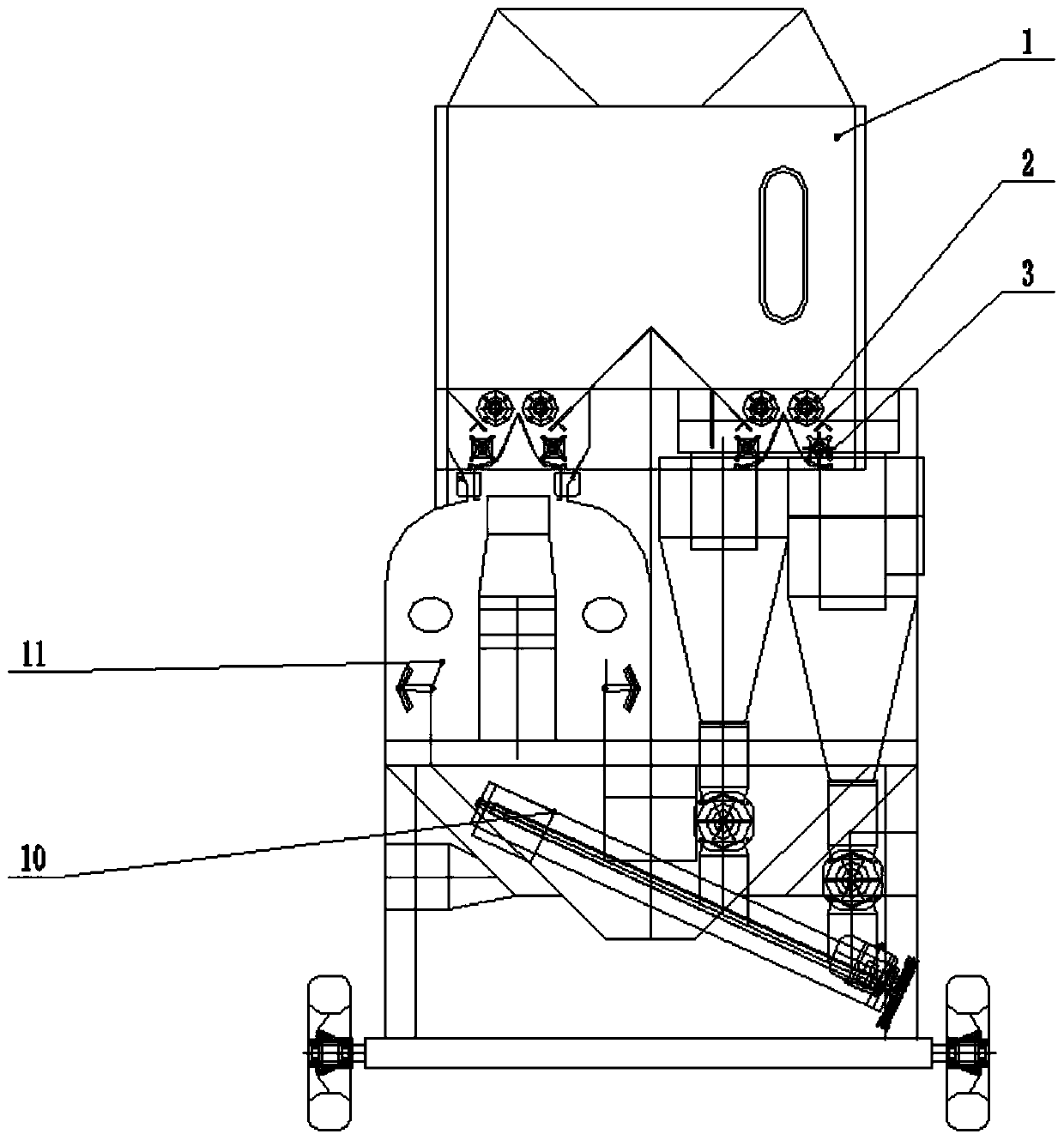

[0039] See attached figure 1 , Attached figure 2 , Attached image 3 , Attached Figure 4 , High-yield grain winnowing machine, including grain storage device 1, demaning roller 2, grain discharge system 3, winnowing box, dust removal system, grain discharge hopper 12, walking system 14, grain discharge system including grain discharge roller, winnowing The box includes a grain flow control system 1, a uniform air box 5, a suction box 6 and an external frame. The uniform air box is provided with an air inlet A and an air outlet B. A grain cutting board 11 is provided between the uniform air box 5 and the suction box 6 for grain and Impurities are separated. The dust removal system includes a fan 7, a cyclone dust collector 8, a wind shutoff device 9, and a screw auger 10. The fan includes an air inlet C and an air outlet D. The lower end of the grain discharge funnel 12 is provided with a gravity movable door 13 for air The selected grain is discharged;

[0040...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap