Separating and conveying system suitable for small-diameter and large-wire-diameter sealing rings

A transmission system and sealing ring technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of falling off the separation track and falling into the feeding port, low efficiency, and easy stacking of sealing rings, so as to achieve high separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

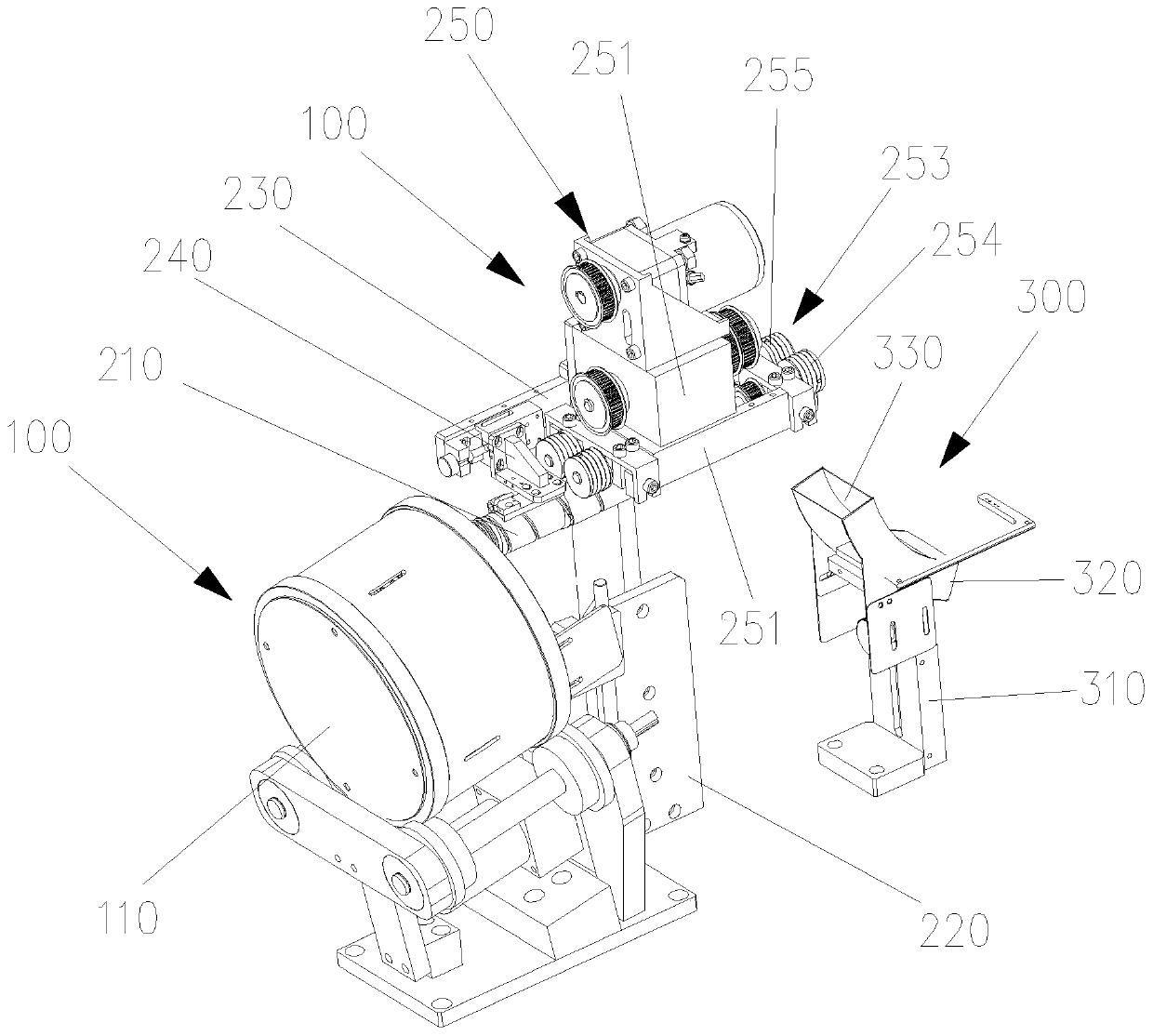

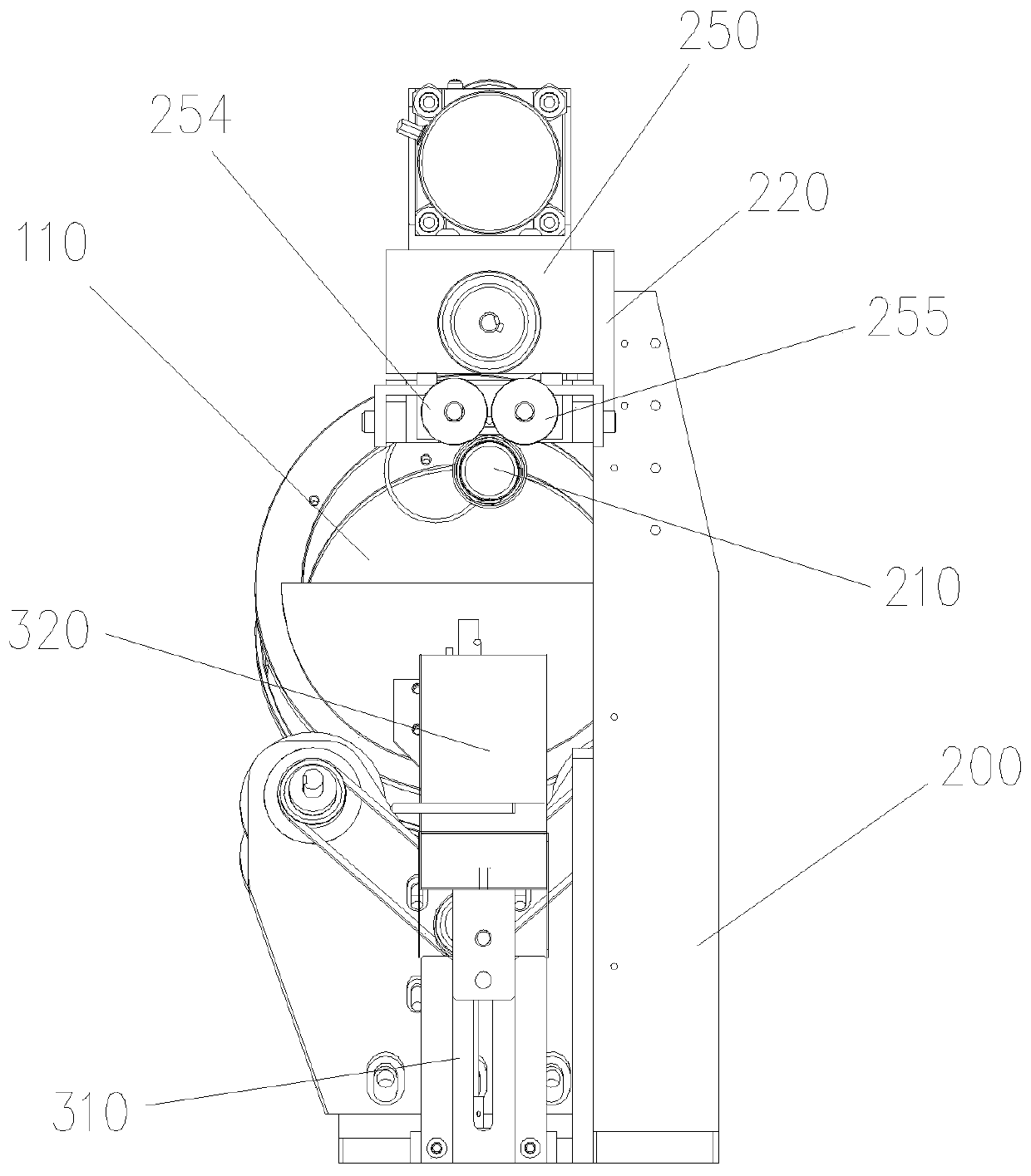

[0020] Please check Figure 1 to Figure 3 , a separation conveying system suitable for sealing rings with small diameter and large wire diameter, including a feeding device 100 , a separating device 200 and a feeding device 300 .

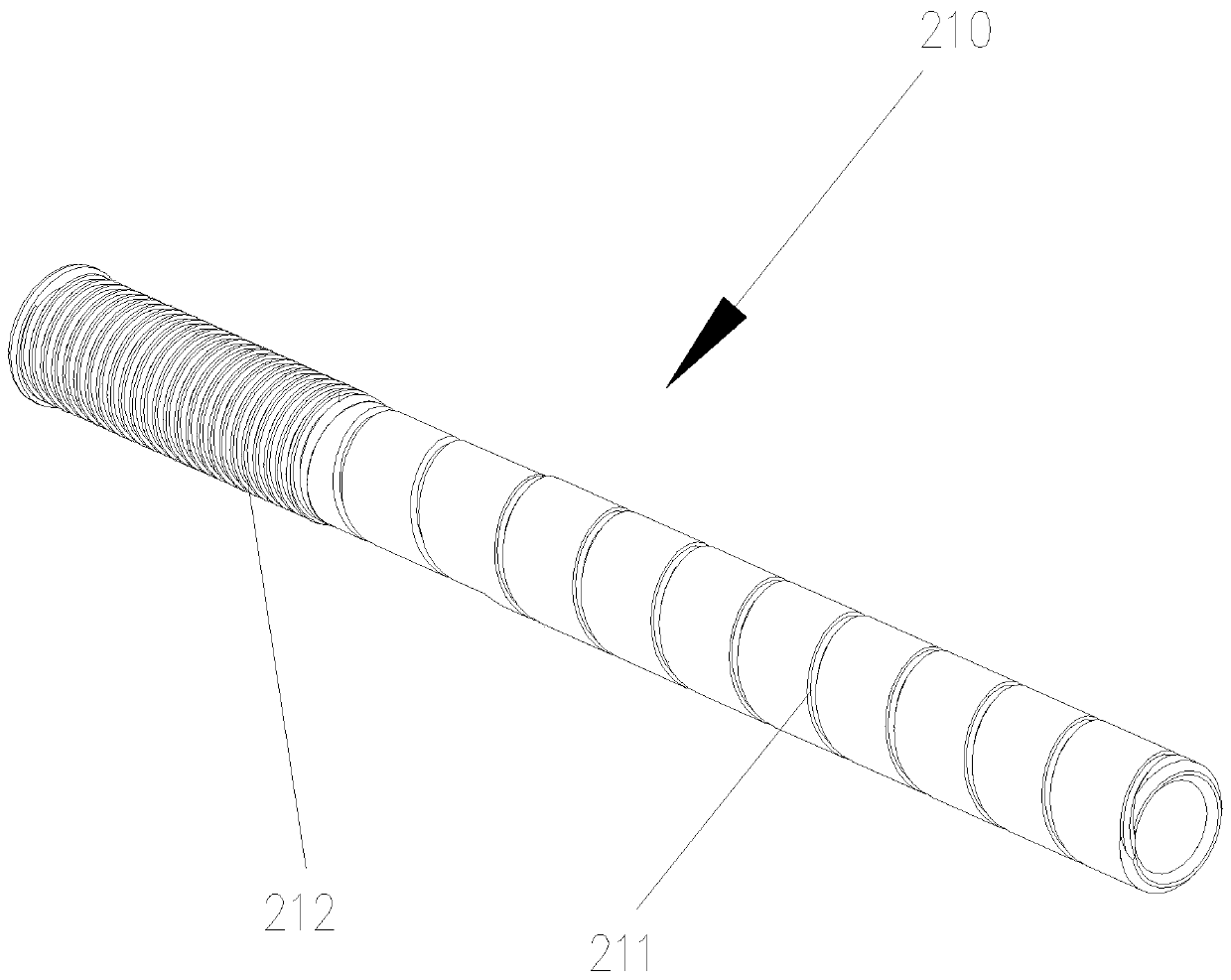

[0021] In this embodiment, the feeding device 100 , the separating device 200 and the feeding device 300 are arranged sequentially from left to right. The feeding device 100 has a drum 110 for accommodating a sealing ring, the separating device 200 has a helical metal rod 210, one end of the helical metal rod 210 extends into the drum 110, and the helical metal rod is matched by the drum 110 210 to realize feeding.

[0022] In this embodiment, the separation device 200 includes a support mechanism 220, and a mounting bar 230 is fixedly mounted on the top of the support mechanism. Magnetic adsorption devices 240 are provided at both ends of the mounting bar 230. The two magnetic adsorption devices 240 A driving device 250 for driving the helical me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap