Printing device of gloves

A printing and glove technology, applied in printing, stamping, etc., can solve problems such as poor quality, high labor intensity, and low efficiency, and achieve the effects of low scrap rate, high printing quality, and high labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

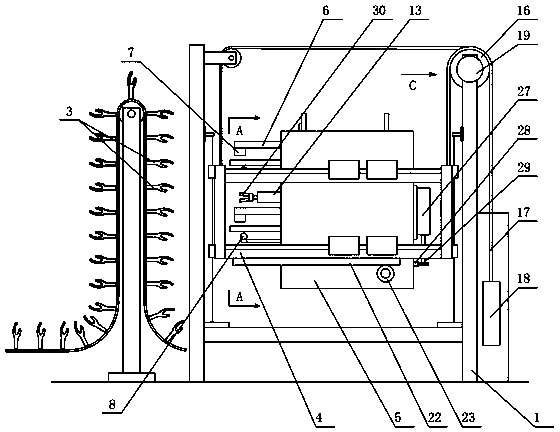

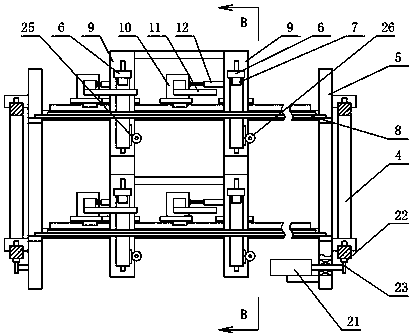

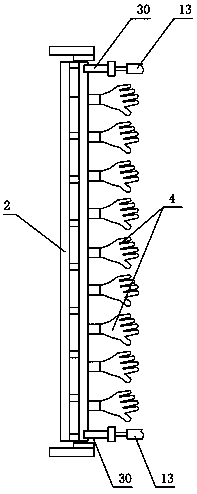

[0020] refer to figure 1 As shown, the present invention provides an embodiment of a glove printing device, for convenience of description, with figure 1 The direction perpendicular to the paper is the lateral direction of the device, figure 1 The left and right direction in the figure is the longitudinal direction of the device. The above glove printing device includes a frame 1, and the frame 1 is connected with a conveyor chain driven by a power device. figure 1 Only a part of the conveyor chain is shown in the diagram, and a hand mold frame 2 is installed between the two opposite conveyor chains. The conveyor chain has a vertical conveyor chain segment running vertically. In this embodiment, the frame 1 of the above-mentioned glove printing device It can be installed separately, and can also form an integral frame with the frame used to support the conveyor chain. The frame is located on the vertical conveyor section running downwards. Of course, it can also be set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com