Chip packaging machine

A packaging machine and chip technology, applied in packaging, transportation packaging, multiple packages, etc., can solve the problems of irreparable, waste of manpower and time, difficult to separate, etc., to avoid vacuum gas leakage, enhance thermal conductivity, Relieve the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

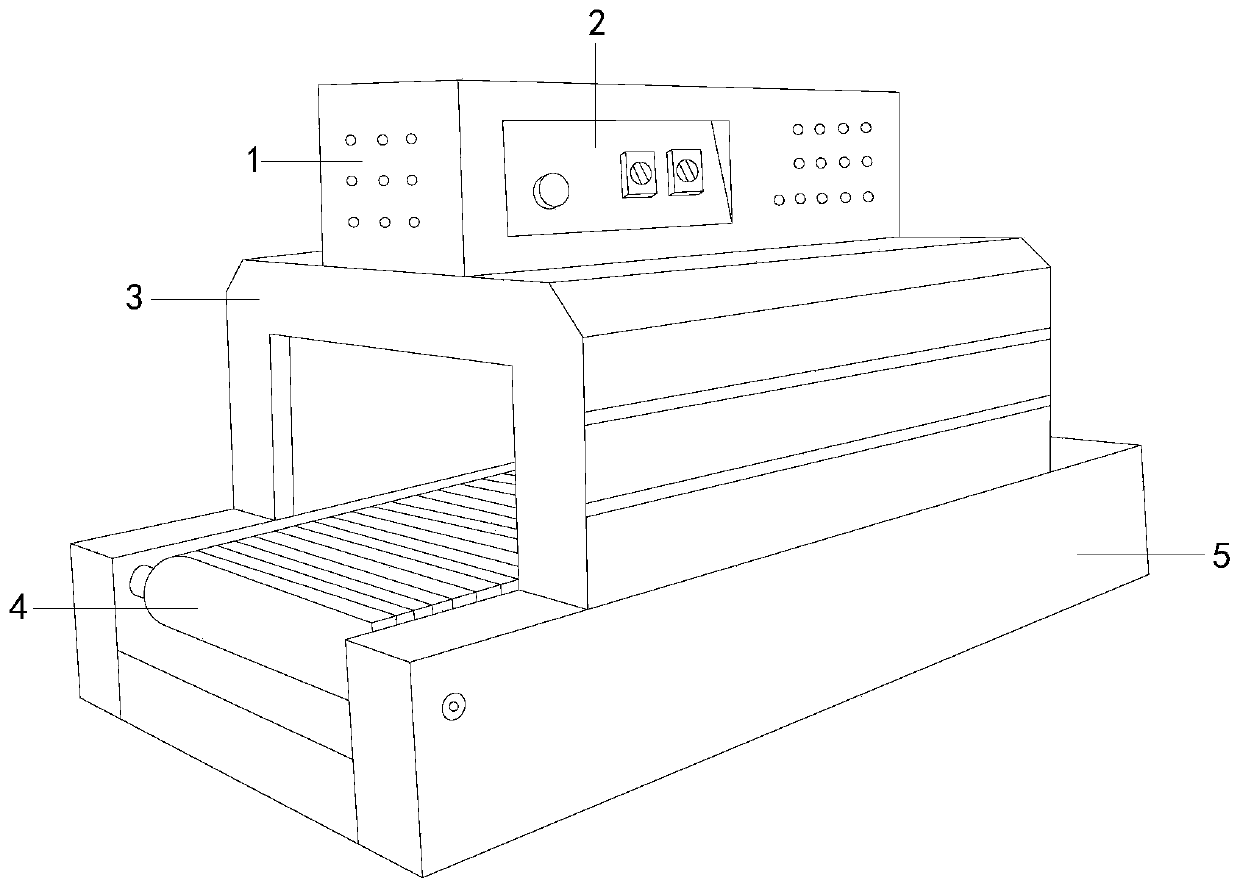

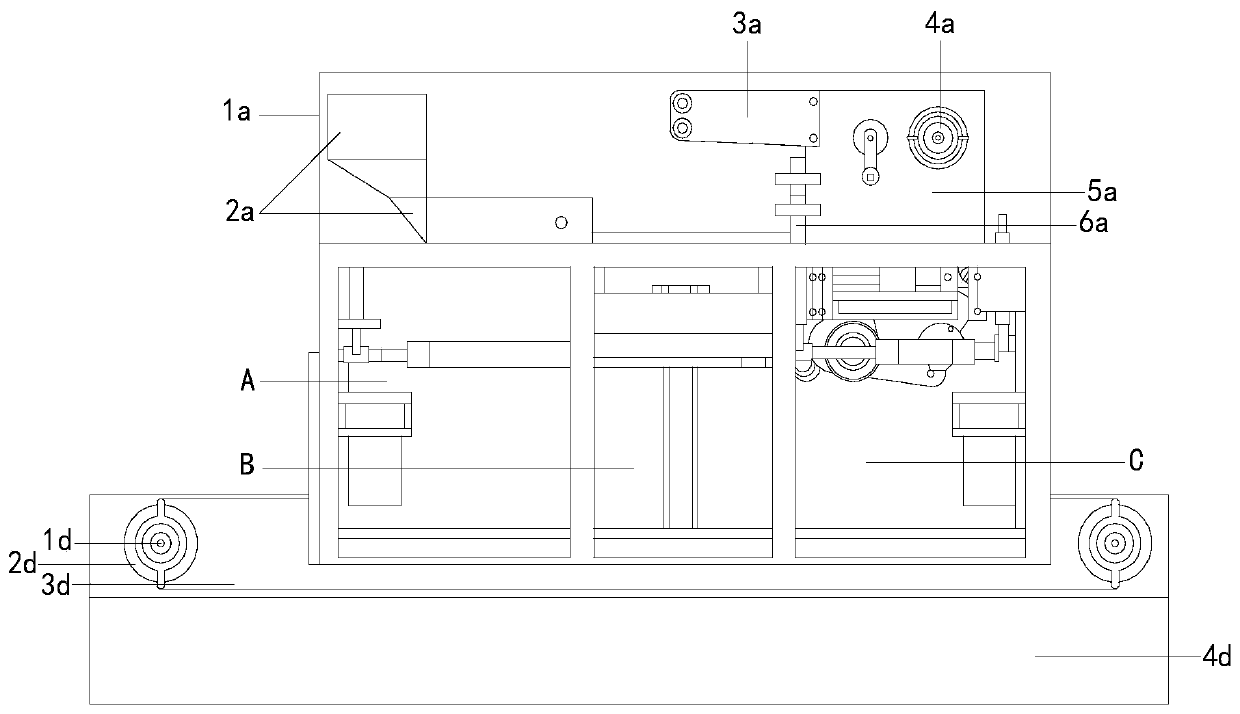

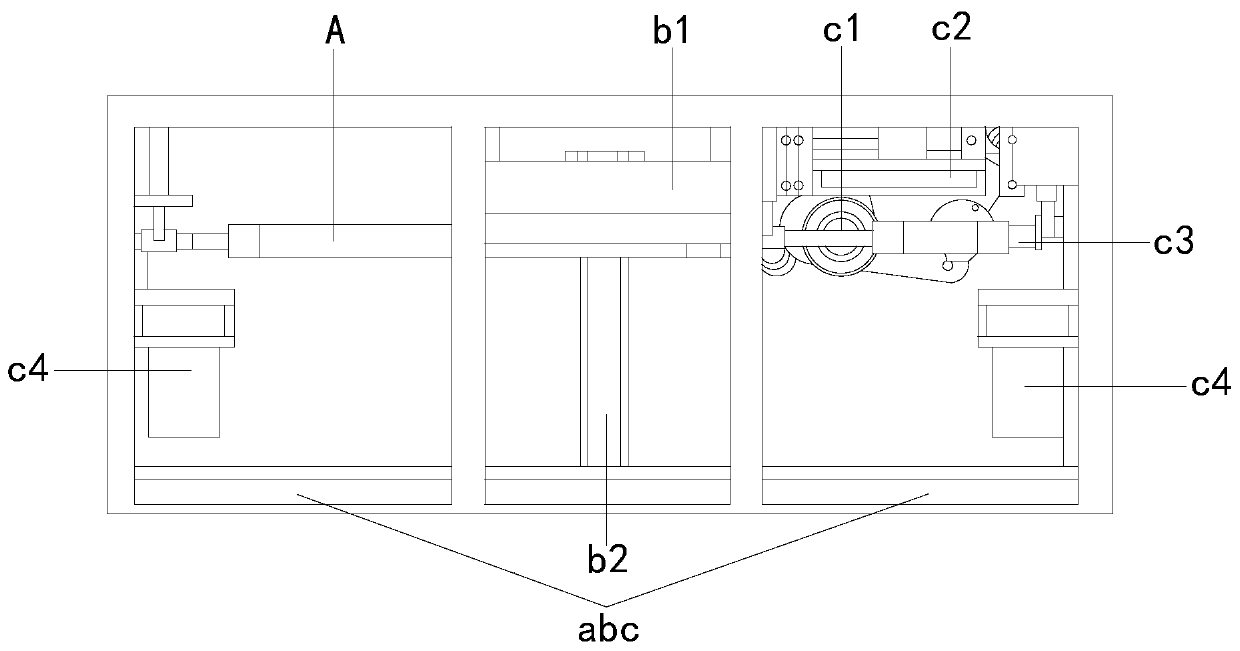

[0026] see figure 1 , the present invention provides a chip packaging machine, the structure of which includes: a console 1, an operating box 2, a pressing mechanism 3, a conveyor belt 4, a base 5, and the console 1 is provided with an operating box 2 and is connected with the pressing mechanism 3. Connected, the pressing mechanism 3 is connected to the conveying tape 4, and the conveying tape 4 is set at the top of the base 5. The console 1 is mainly used to control the movement and operation of the structural components in the pressing mechanism, and the operation panel 2 is used to control the opening of the power supply. The operation mode of the equipment can be selected by the buttons and knobs that are closed and have corresponding functions. The pressing mechanism 3 mainly presses and separates the outer packaging bags of the chips to avoid mixing different types of chips. The transfer structure during packaging, relying on it to complete the steps of chip self-assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com