Automatic four-axis cast film winding machine

A cast film and winder technology, which is applied in the direction of coiling strips, thin material processing, transportation and packaging, etc., can solve the problem of reducing the service life of the air shaft and the installation components of the air shaft, and cannot effectively improve the casting film. Rewinding speed, poor rewinding effect and other problems, to achieve the effect of saving rewinding time, reducing safety and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

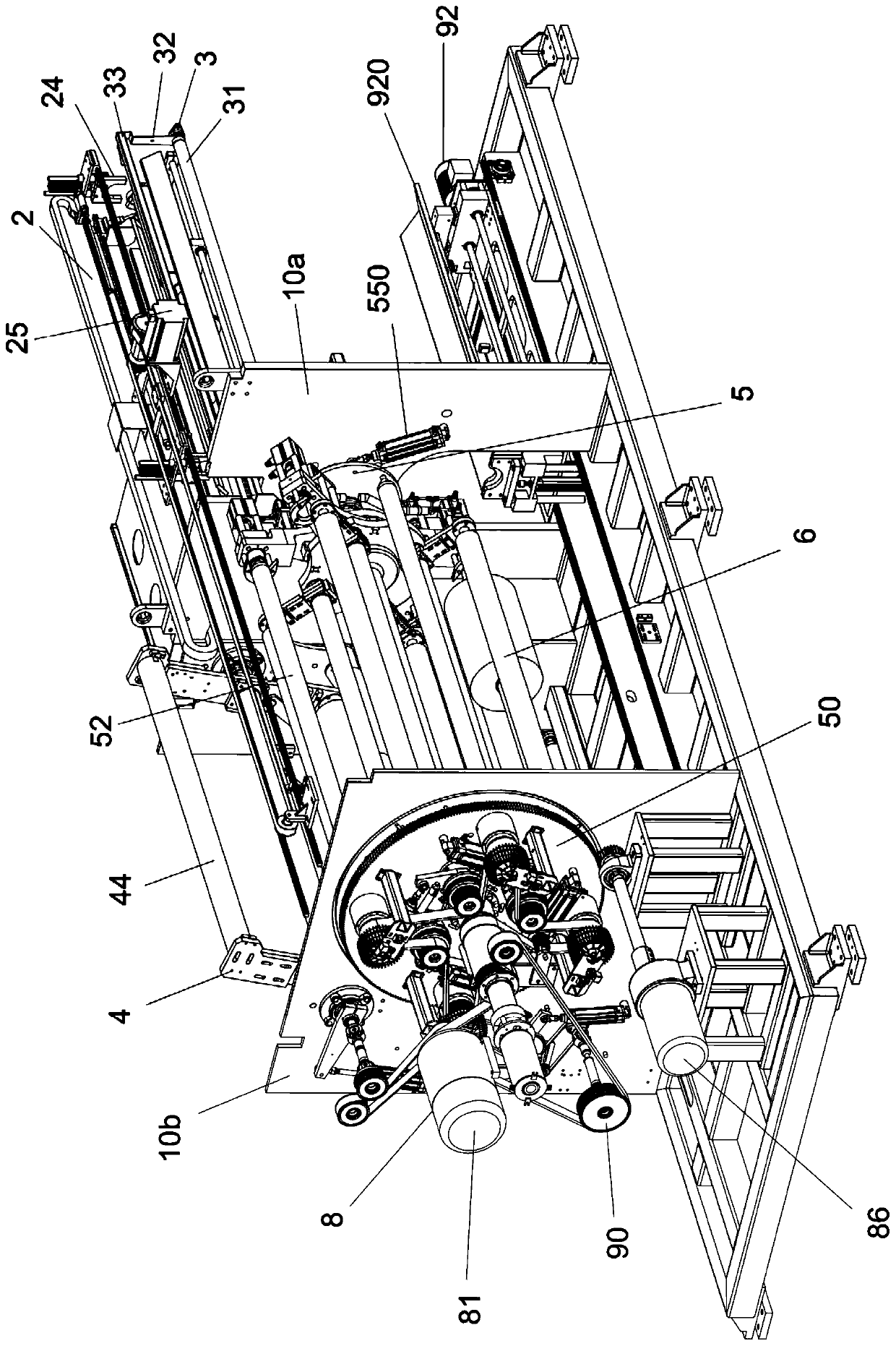

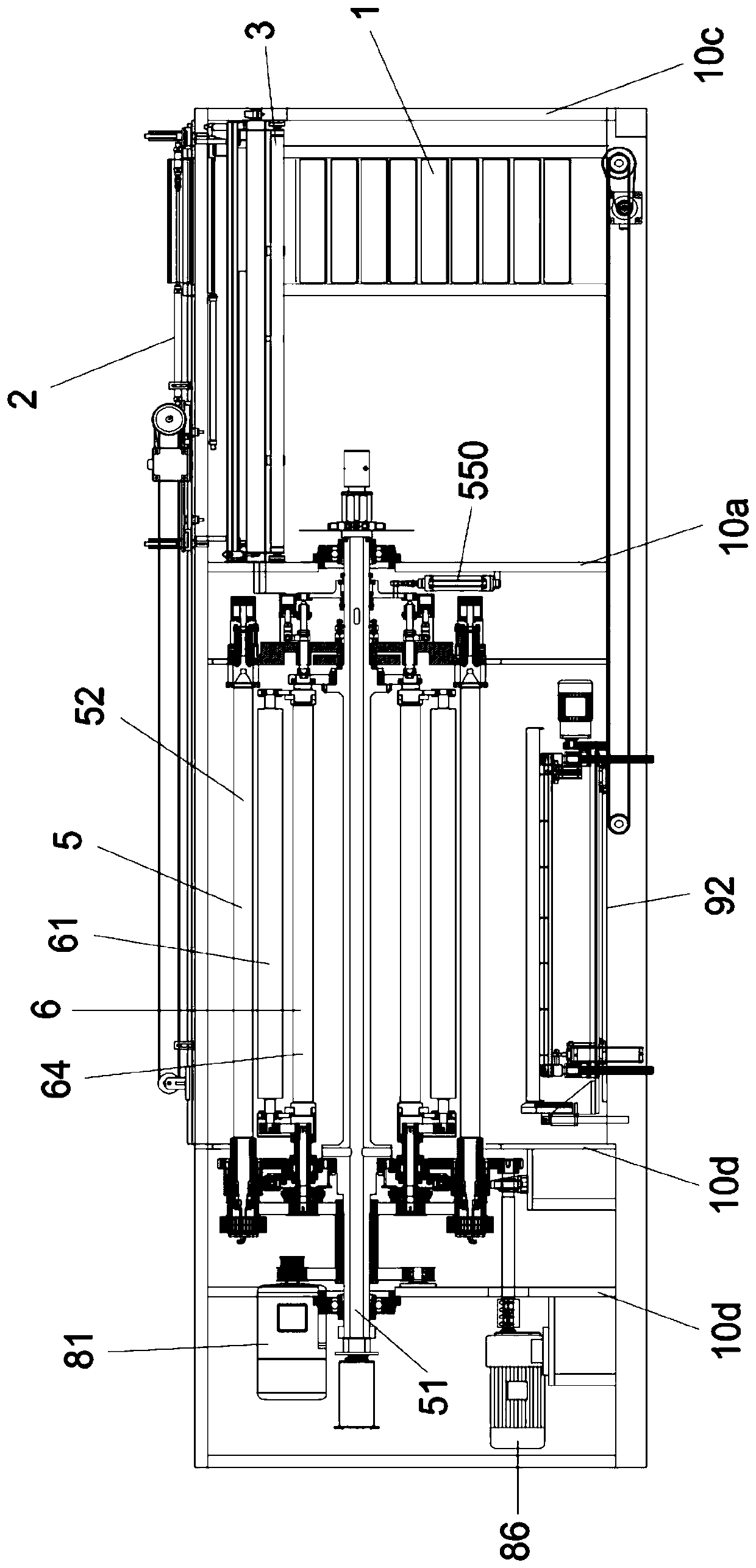

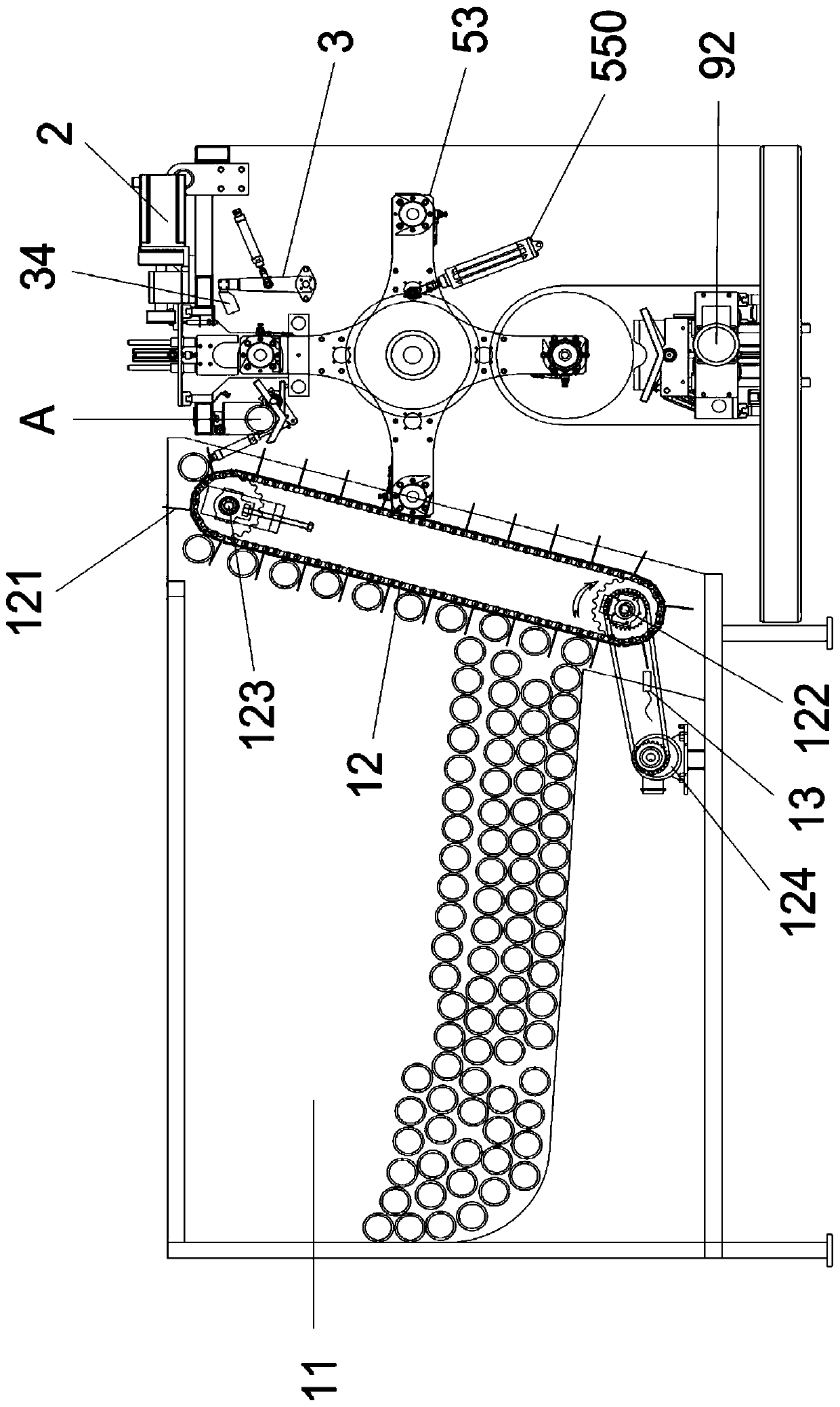

[0085] Embodiment 1: Concrete structure and work flow of paper tube arrangement assembly 1

[0086] Please refer to image 3 , Figure 4 with Figure 5 , the paper tube arrangement assembly 1 includes a paper tube box 11, and the paper tube box 11 is used for storing paper tubes. One side of the paper tube box 11 is provided with a transport crawler 12 for transporting paper tubes. In order to facilitate the transport of paper tubes by the transport track 12, the bottom surface of the paper tube box 11 is inclined, and the bottom surface of the paper tube box 11 is away from the One side of the transport crawler 12 is inclined to the side close to the transport crawler 12 . A plurality of crawler spacers 121 are equidistantly arranged on the transport track 12 , and each single paper tube moves to two adjacent track spacers 121 and is transported by the transport track 12 .

[0087] Both ends of the transport crawler 12 are provided with a transport driving wheel 122 and a...

Embodiment 2

[0099]Embodiment 2: Concrete structure and work flow of the paper tube assembly 2

[0100] Please refer to Figure 4 , Image 6 , Figure 7 with Figure 8 , the paper tube assembly 2 includes a sleeve seat 21 for supporting the paper tubes. As described in Embodiment 1, when the arranged paper tubes are moved from the paper tube arrangement assembly 1 to the paper tube assembly 2 for threading When the tubes are working, the arranged paper tubes are moved from the transfer base 14 to the sleeve base 21 . A third photoelectric switch 22 is arranged on one side of the casing socket 21 . When the third photoelectric switch 22 detects that there is no paper tube on the sleeve seat 21, the third photoelectric switch 22 drives the transfer seat 14 to rotate, and the paper tube on the transfer seat 14 moves to the sleeve. on the socket 21.

[0101] A casing baffle 211 is arranged on one side of the casing seat 21, and the casing baffle 211 prevents the paper tube from rolling o...

Embodiment 3

[0112] Embodiment 3: Concrete structure and work flow of defective component 3

[0113] Please refer to figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 , Figure 9 , Figure 10 The purpose of the rejected product assembly 3 is to remove the paper tube that cannot be installed on the air shaft 52 due to deformation out of the paper tube assembly 2 . And for the paper tube assembly 2, when the sleeve work is performed in the paper tube assembly 2, the push claws 24 in the paper tube assembly 2 mainly push the paper tube to perform the sleeve. When the paper tube cannot be sleeved on the air expansion shaft 52, the push claw 24 will be pushed by the paper tube. Therefore, the paper threading tube assembly 2 is also provided with a protection cylinder 27 and a travel switch 28 installed between the push claw 24 and the clamping cylinder 26 . The protection cylinder 27 prevents the paper tube pushing claws 24 from damaging the components in the paper tube assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com