Self-lubricating polyamideimide varnish, insulating coating, insulated wire, coil and motor

A technology of polyamide-imide varnish and polyamide-imide, applied in the field of self-lubricating polyamide-imide varnish, can solve the problem of uneven lubricity, difficulty in uniform dispersion of lubricants, easy adsorption of dust and foreign matter by lubricants, etc. problem, to achieve the effect of excellent lubricity and improved lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

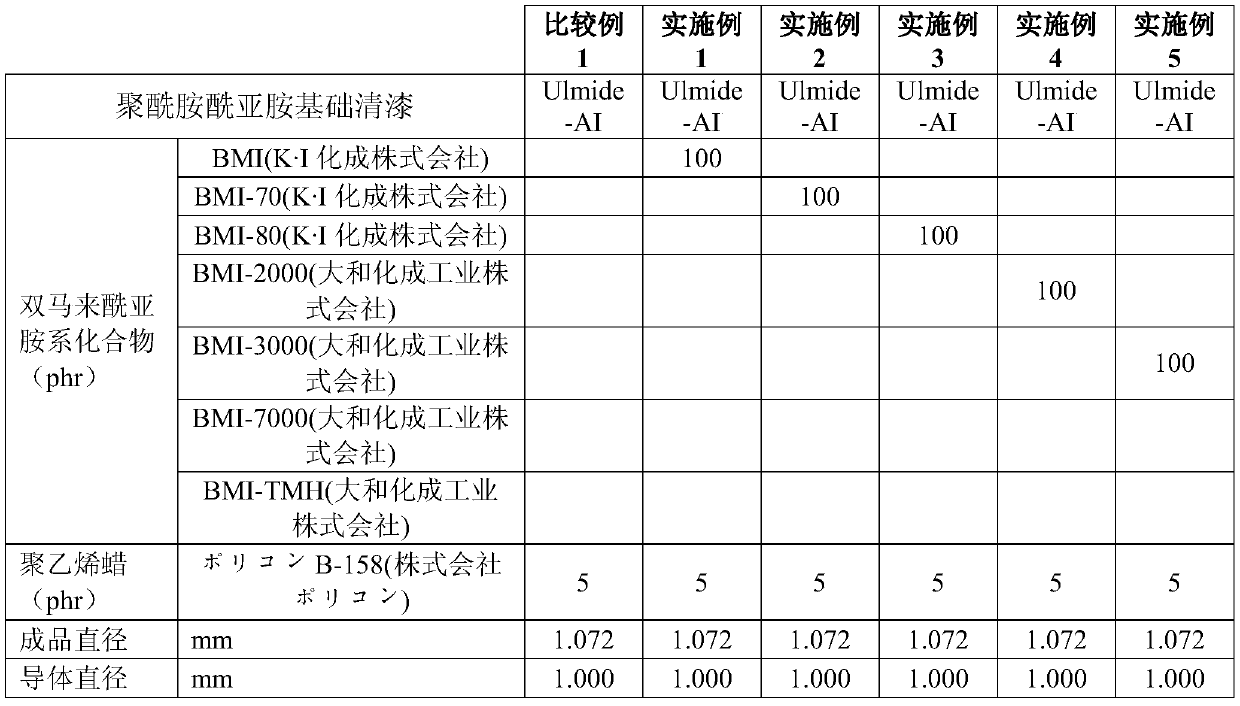

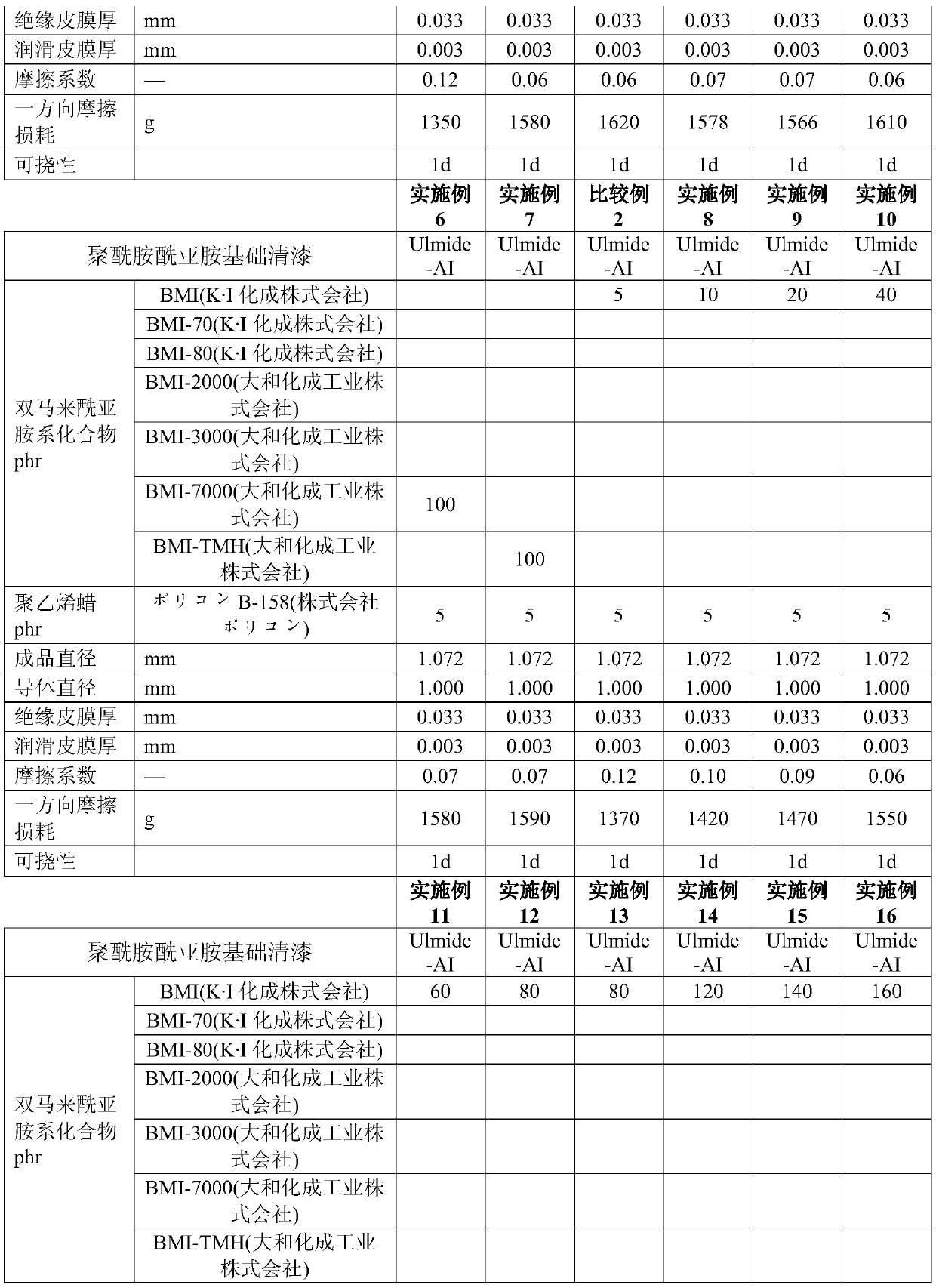

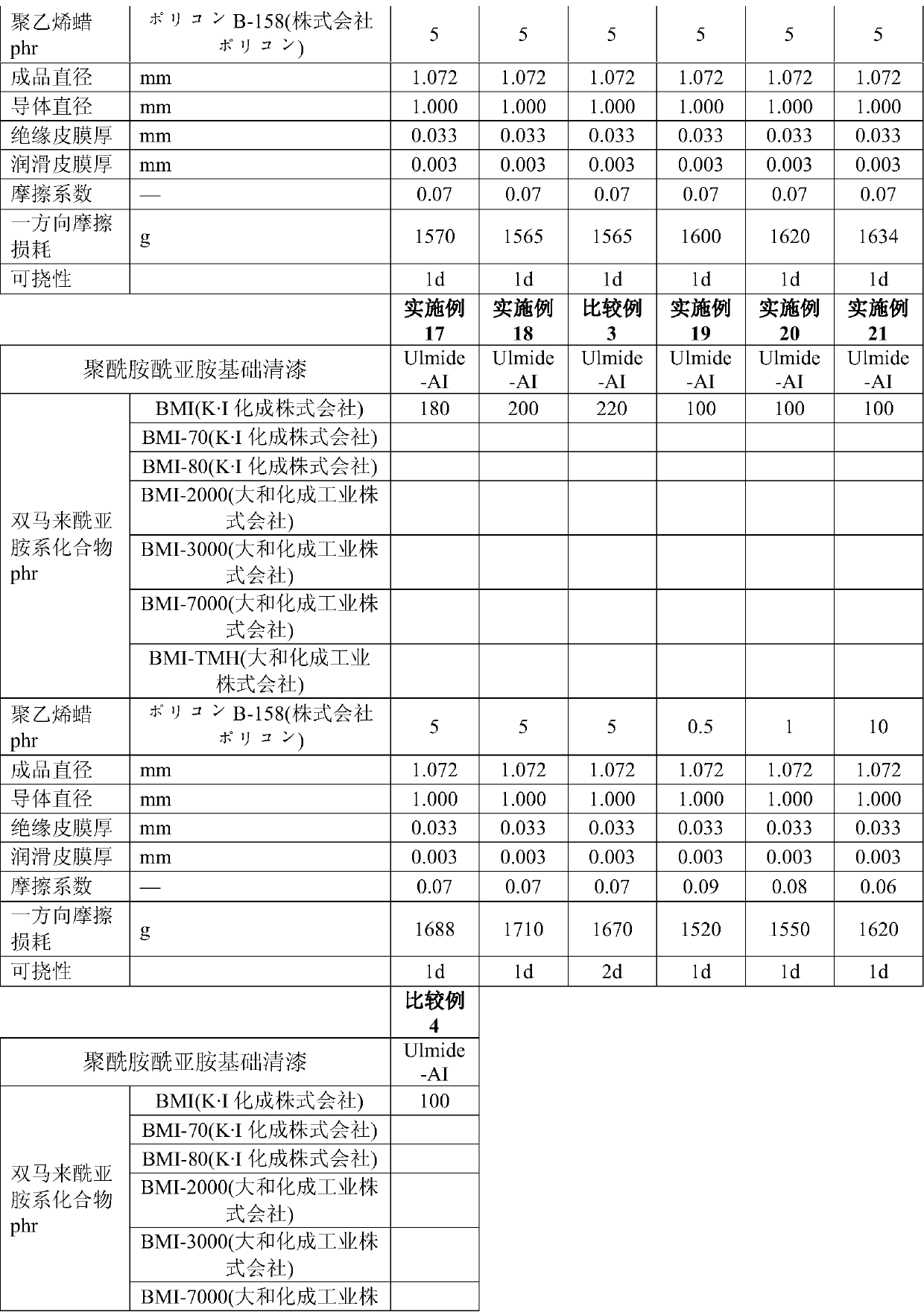

[0016] The present invention will be further described below through the following embodiments. It should be understood that the following embodiments are only used to illustrate the present invention, not to limit the present invention.

[0017] A self-lubricating polyamide-imide varnish according to one embodiment of the present invention includes a polyamide-imide resin, a bismaleimide compound, and a lubricant.

[0018] The lubricant in the self-lubricating polyamide-imide varnish can improve the lubricity, and the bismaleimide compound can make the lubricant penetrate into the film formed by the self-lubricating polyamide-imide varnish (hereinafter also referred to as "self-lubricating") Insulation film", "film") surface, thereby further improving the lubricity of the film.

[0019] The polyamideimide used as the base resin is not particularly limited, and polyamideimides obtained by conventional methods, such as polyamides obtained by directly reacting tricarboxylic anhy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com