Prestress gradient section UHPC beam bridge

A prestressed, gradient technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of affecting structural quality, prefabricated bridge deck drop angle defects, steel collision and fracture, etc., to avoid potential safety hazards, size reduction, reduction high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] This embodiment takes a pedestrian bridge in a certain city as an example for illustration. Since the bridge is located in the central area of the city, in order to reduce the impact on urban traffic, the construction method of prefabricating the bridge in the factory and overall hoisting and installation on site is adopted.

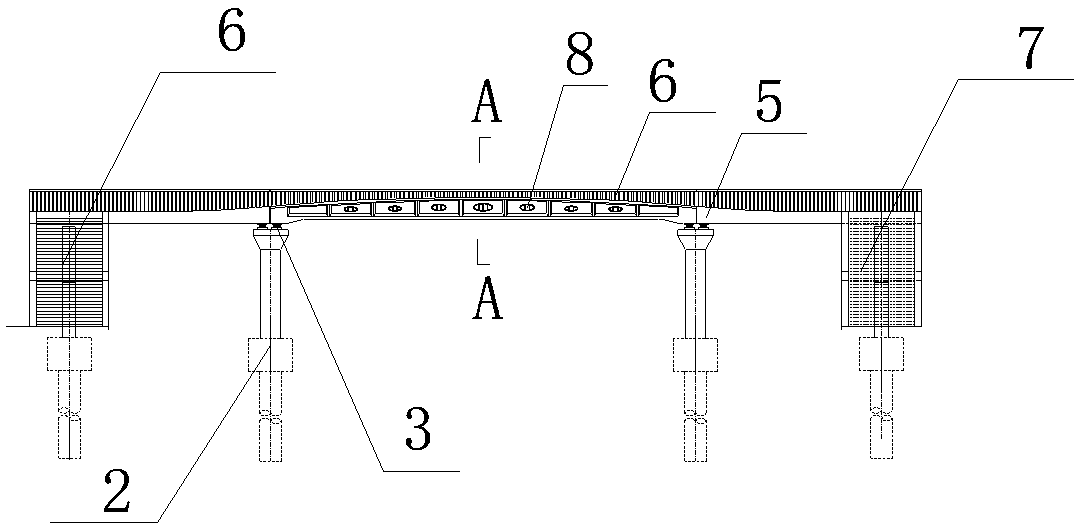

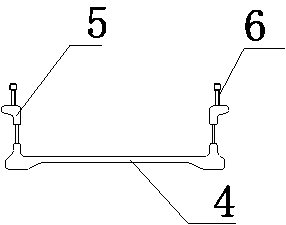

[0020] Such as figure 1 and figure 2 As shown, the prestressed gradient cross-section UHPC girder bridge of the present embodiment is used as the middle girder bridge of the flyover, including a superstructure 1, a substructure 2, and a support 3 arranged between the superstructure 1 and the substructure 2; the superstructure 1 is composed of a bottom plate 4 and webs 5 located on both sides of the bottom plate 4. The upper structure 1 is an integrated structure with a U-shaped cross section and is prefabricated by UHPC. The web 1 is provided with prestressed pipes ( not shown in the figure). The middle girder bridge both sides of overpass ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com