Forming method of composite foundation pile and grouting member of composite foundation pile

A forming method and composite foundation technology, which can be used in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of reduced bearing capacity of composite foundation piles, small shrinkage and expansion rates of prefabricated piles, hidden dangers of engineering quality and safety, etc. The effect of ensuring reliable contact and eliminating hidden dangers of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

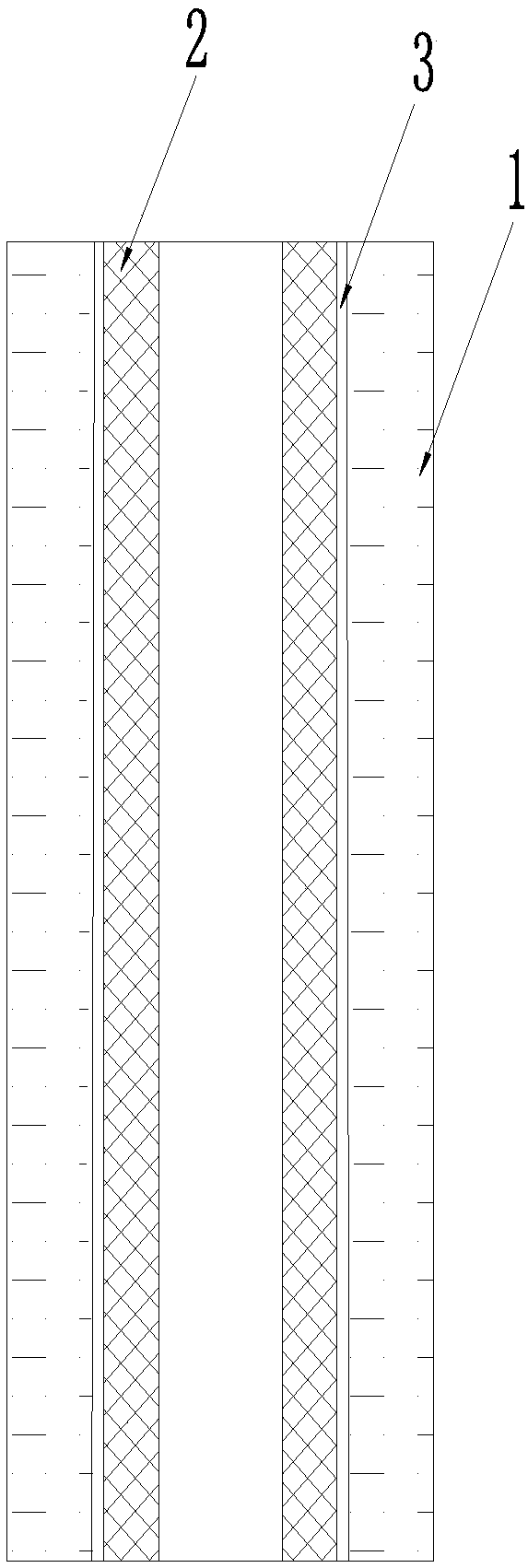

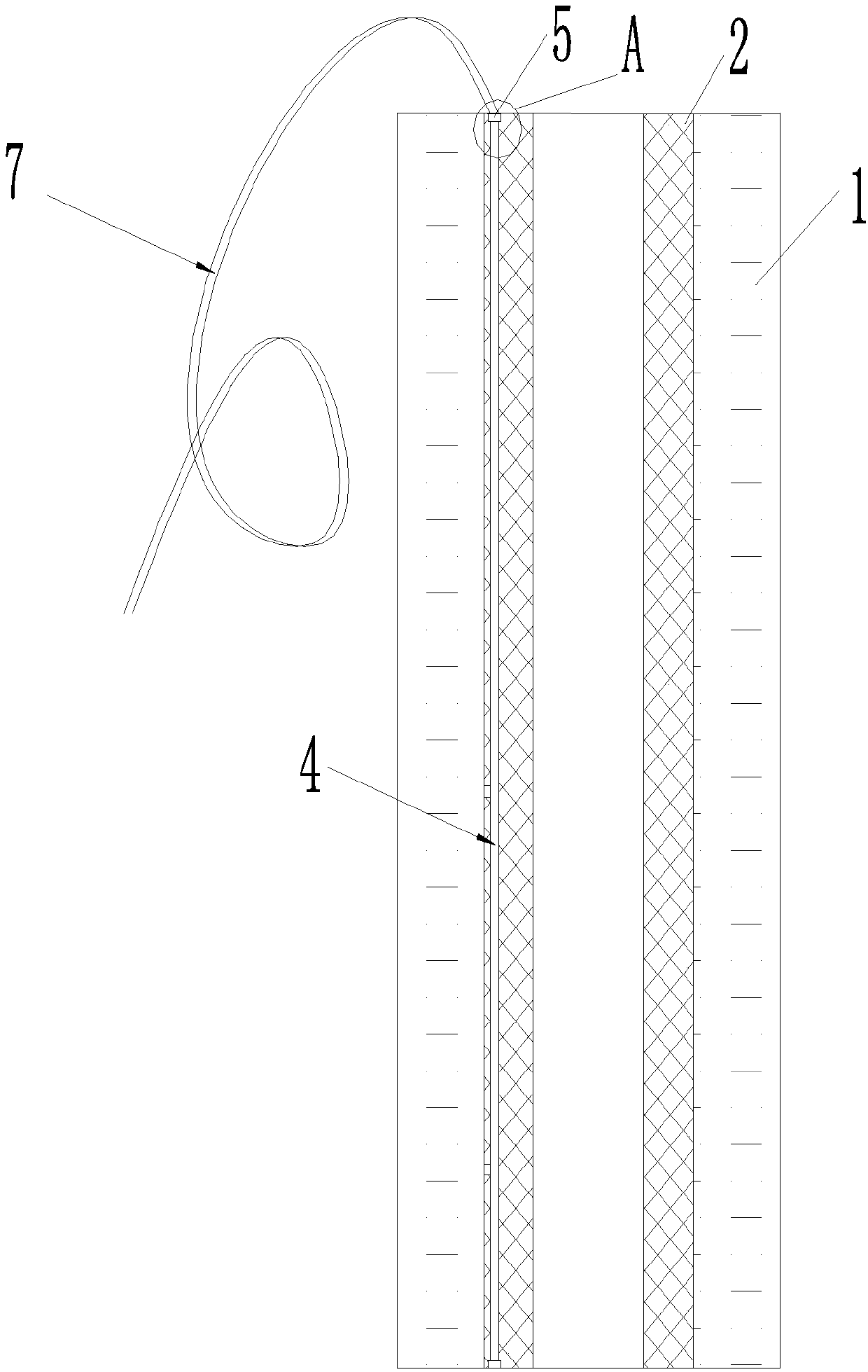

[0075] The first embodiment: Please first refer to Figure 2 to Figure 7. In the first embodiment, the grouting components include the prefabricated pile 2 located in the foundation and the cement-soil solidification layer covering the periphery of the prefabricated pile 2. The cement-soil solidification layer is formed by mixing cement and soil, and the prefabricated pile 2 A grouting pipe 4 is also arranged on the top, and the grouting pipe 4 is used for pouring cement slurry into the gap between the cement-soil solidified layer and the outer surface of the prefabricated pile 2, and the external pipeline 7 is used for connecting with the pulping machine.

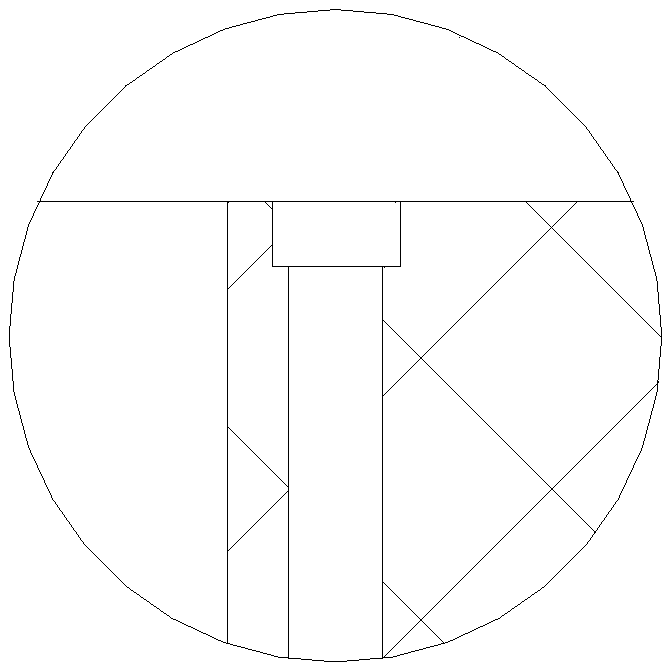

[0076] The prefabricated pile 2 is a hollow pile, and the grouting pipe 4 is pre-embedded in the prefabricated pile 2. In order to realize the connection of the grouting pipes 4 in two adjacent sections of the prefabricated pile 2, a connecting cavity 5 is provided on the top of the prefabricated pile 2. Such as figure 2...

no. 2 example

[0077] The second embodiment: please refer to Figure 8 to Figure 11. The difference from the first embodiment is that the grouting pipe 4 in this embodiment is located on the outer surface of the prefabricated pile 2, so the grouting pipe 4 can be set at the construction site, and the pipe buckle 8 can be used to fasten the grouting pipe 4 at the construction site. The grouting pipe 4 is fixedly arranged on the outer surface of the prefabricated pile 2, and the grouting pipe 4 is lowered into the cement soil together with the prefabricated pile 2, and the external pipeline 7 is used for connecting with the pulping machine.

[0078] In the second embodiment, the prefabricated pile 2 is a hollow pile, such as Figure 9 to Figure 11. The cross-section of the hollow pile can be circular, rectangular or regular hexagonal. Of course, the cross-sectional shape of the hollow pile can also be other shapes. The specific shape of the cross-section of the hollow pile has no effect on the...

no. 3 example

[0079] The third embodiment: please refer to Figure 12 to Figure 15. The difference from the second embodiment is that the grouting pipe 4 in this embodiment specifically includes a grouting main pipe 41 and a grouting branch pipe 42, wherein the grouting branch pipe 42 is pre-embedded in the prefabricated pile 2 and distributed along the lateral direction, One end of the grouting branch pipe 42 leads to the outer surface of the prefabricated pile 2 , the grouting main pipe 41 is vertically arranged, and the grouting main pipe 41 communicates with the other end of the grouting branch pipe 42 . The prefabricated pile 2 in this embodiment is also a hollow pile, and the grouting main pipe 41 is arranged in the middle hole of the prefabricated pile 2, as Figure 12 As shown, the grouting main pipe 41 can also be set in the middle hole of the prefabricated pile 2 at the construction site through the pipeline buckle 8, and then it is lowered into the cement soil together with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com