Reactor and step-up circuit

A technology of reactors and circuits, applied in circuits, inductors, variable inductors, etc., can solve problems such as increased ripple current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

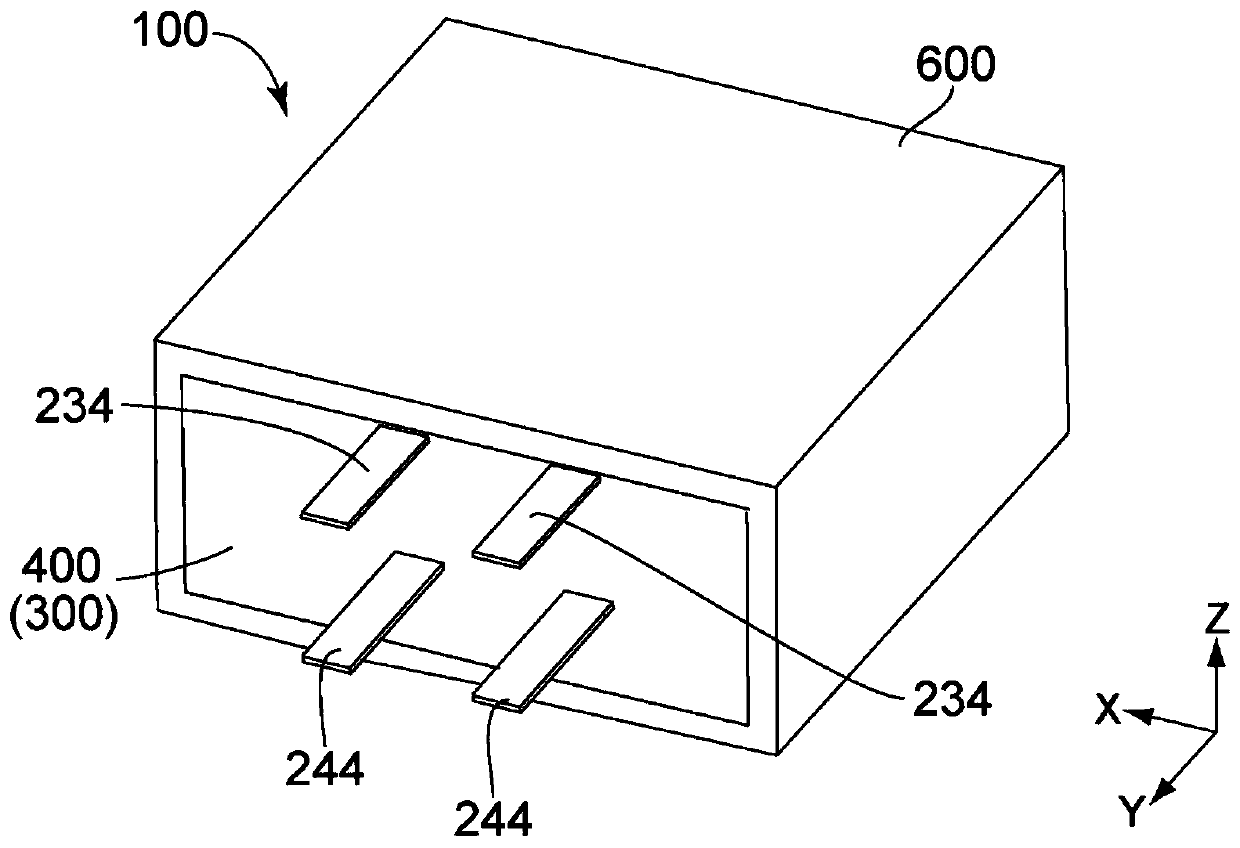

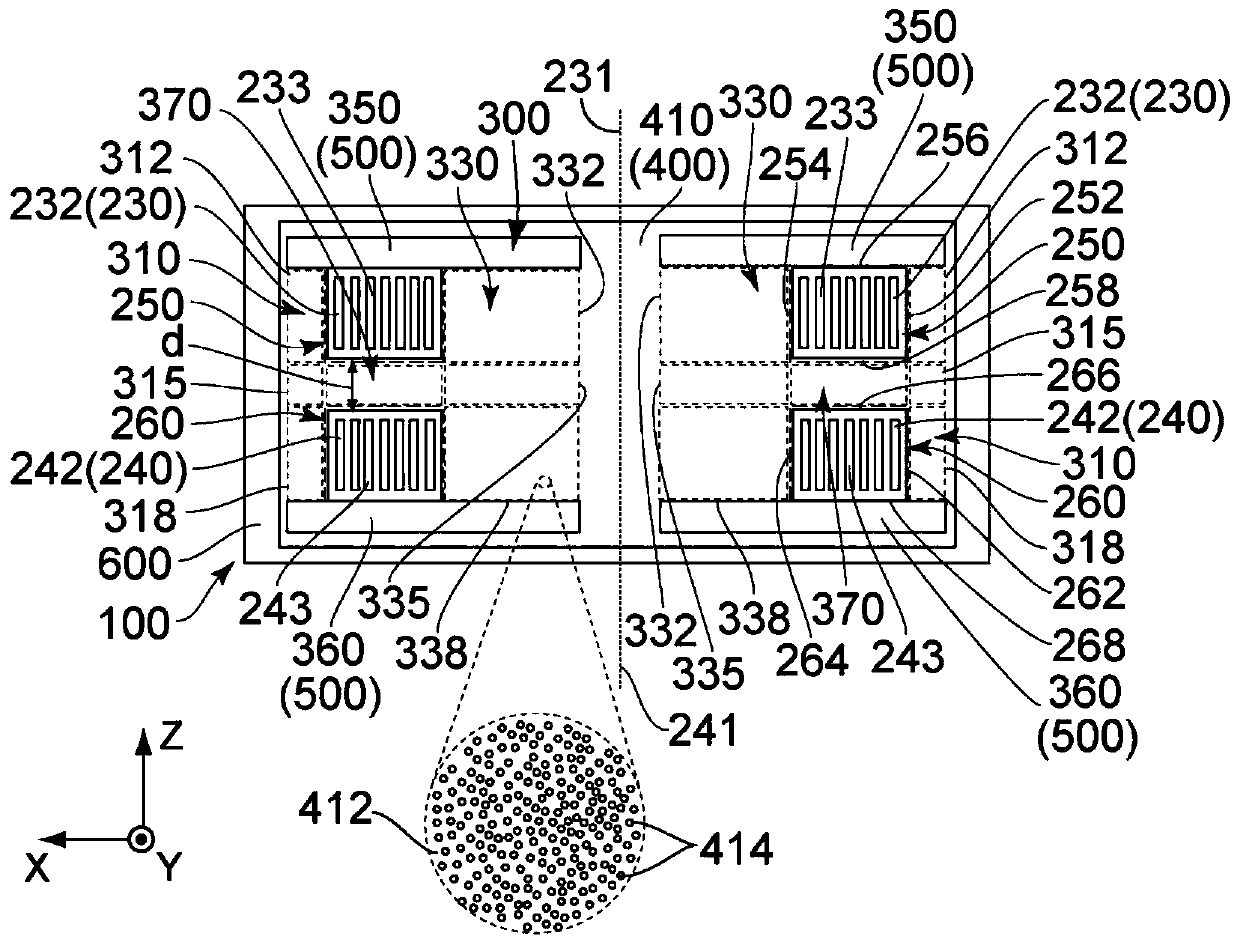

[0023] Such as figure 2 As shown in , the reactor 100 according to the first embodiment of the present invention includes a first coil 230 , a second coil 240 , a core 300 and a case 600 . Each of the first coil 230 and the second coil 240 is embedded in the core 300 .

[0024] see figure 1 and figure 2 , the first coil 230 of this embodiment includes a first coil body 232 and two first end portions 234 . The first coil main body 232 has a first winding axis 231 extending in the up-down direction. The two first end portions 234 respectively extend from opposite ends of the first coil body 232 . In this embodiment, the up and down direction is the Z direction. Specifically, it is assumed that upward is the positive Z direction and downward is the negative Z direction. The first coil main body 232 of this embodiment is formed by level-winding a flat wire 233 . Although the first coil 230 of the present embodiment is a single-layer coil, the present invention is not lim...

no. 2 example

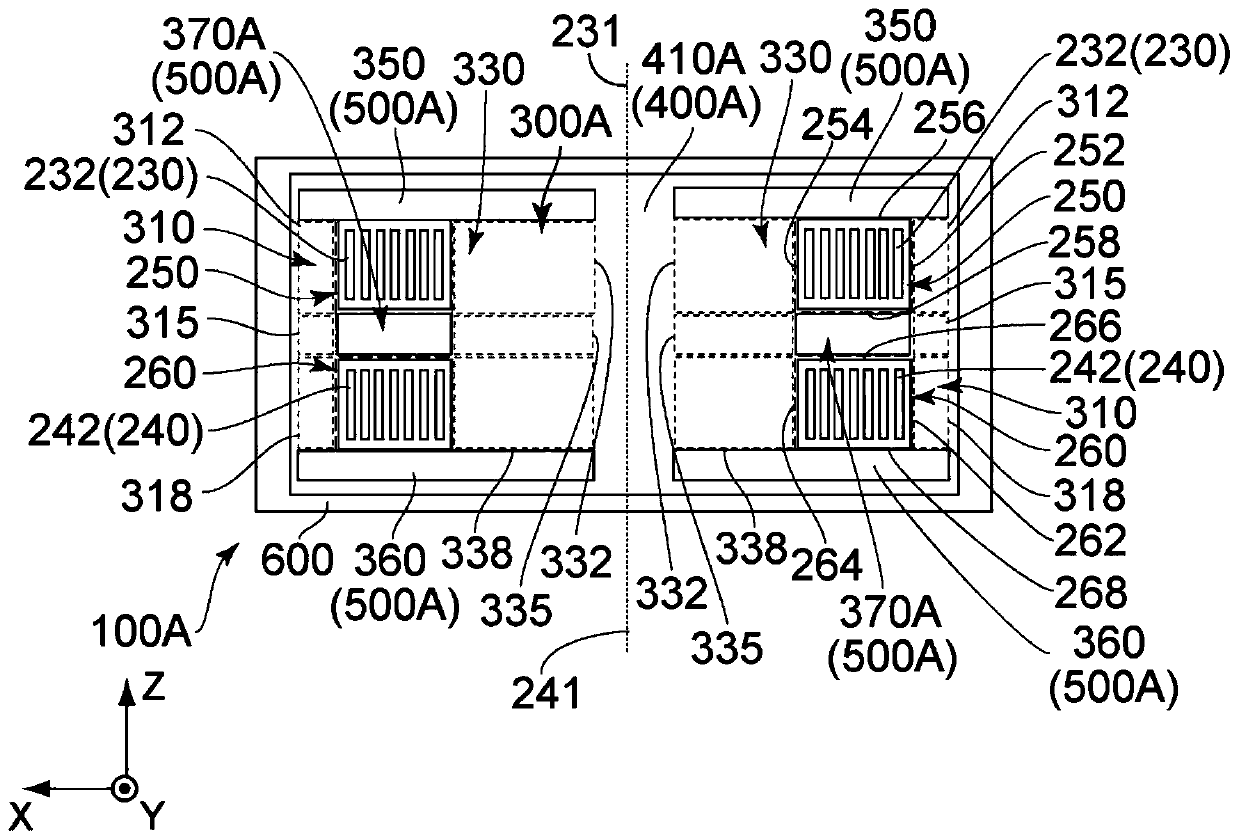

[0059] Such as image 3 As shown in , in addition to the core 300A, the reactor 100A according to the second embodiment of the present invention has the same figure 1 and figure 2 Each of the reactors 100 shown in the foregoing first embodiment has the same structure. therefore, image 3 Components of the reactor 100A shown in , which are the same as those of the reactor 100 of the first embodiment, are denoted by the same reference numerals as those of the reactor 100 of the first embodiment. Regarding directions and orientations in this embodiment, the same expressions as those of the first embodiment will be used hereinafter.

[0060] see image 3 , The core 300A of this embodiment is made of a first member 400A and a second member 500A. The second member 500A of this embodiment is a powder core. The first member 400A of this embodiment is a core made of a composite magnet 410A including hardened binder 412 and magnetic particles 414 . Magnetic particles 414 are di...

no. 3 example

[0068] Such as Figure 4 As shown in , in addition to the core 300B, the reactor 100B according to the third embodiment of the present invention has the same figure 1 and figure 2 Each of the reactors 100 shown in the foregoing first embodiment has the same structure. therefore, Figure 4 Components of the reactor 100B shown in , which are the same as those of the reactor 100 of the first embodiment, are denoted by the same reference numerals as those of the reactor 100 of the first embodiment. Regarding directions and orientations in this embodiment, the same expressions as those of the first embodiment will be used hereinafter.

[0069] see Figure 4 , The core 300B of this embodiment is made of a first member 400B and a second member 500B. The second member 500B of this embodiment is a powder core. The first member 400B of the present embodiment is a core made of a composite magnet 410B including hardened binder 412 and magnetic particles 414 . Magnetic particles 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com