Coil parts

A technology of coil components and coils, applied in transformer/inductor parts, electrical components, transformer/inductor coils/windings/connections, etc., can solve the problems of reduced inductance, high coupling coefficient, and difficulty in obtaining coupling coefficient, etc. Improve the effect of inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

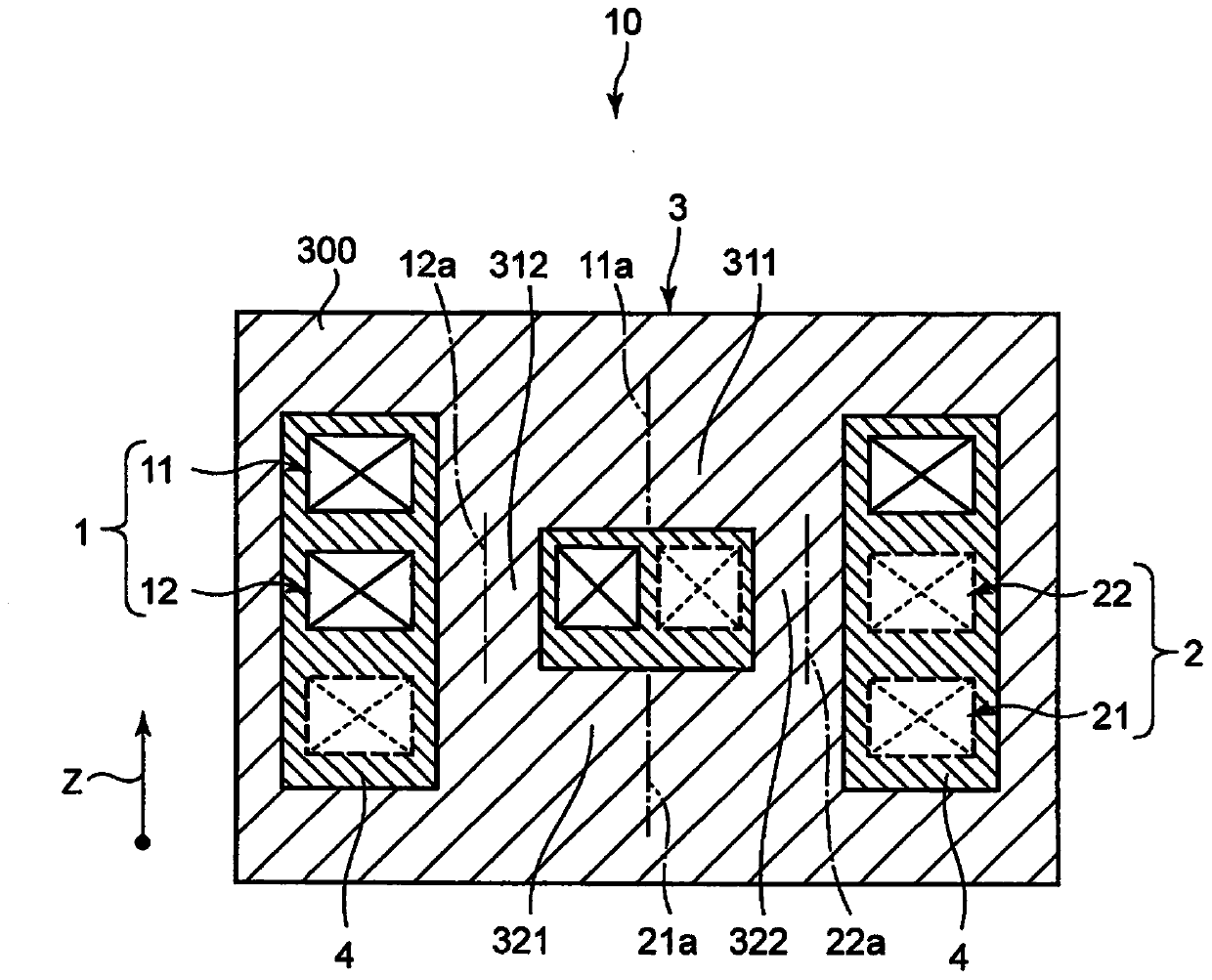

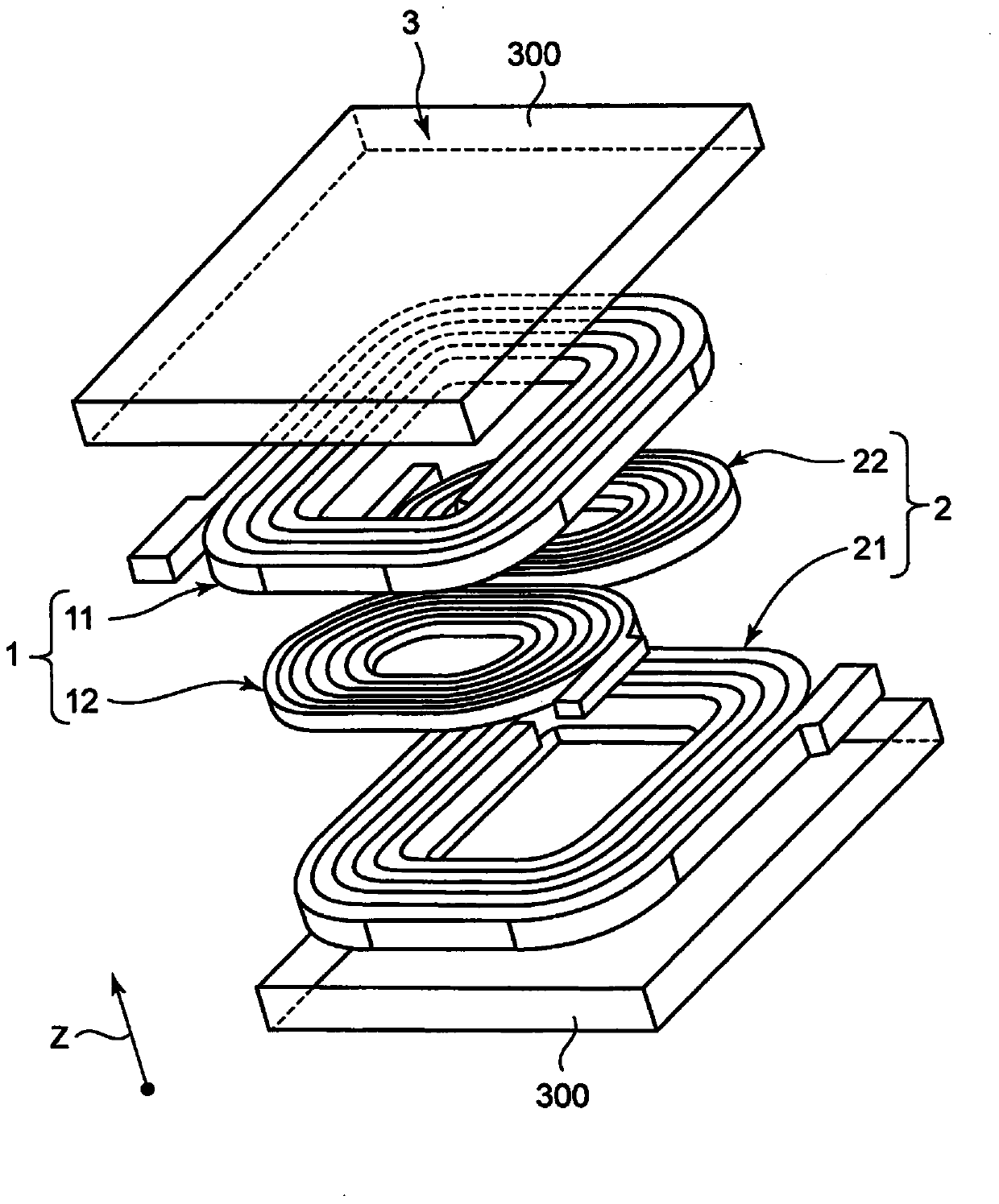

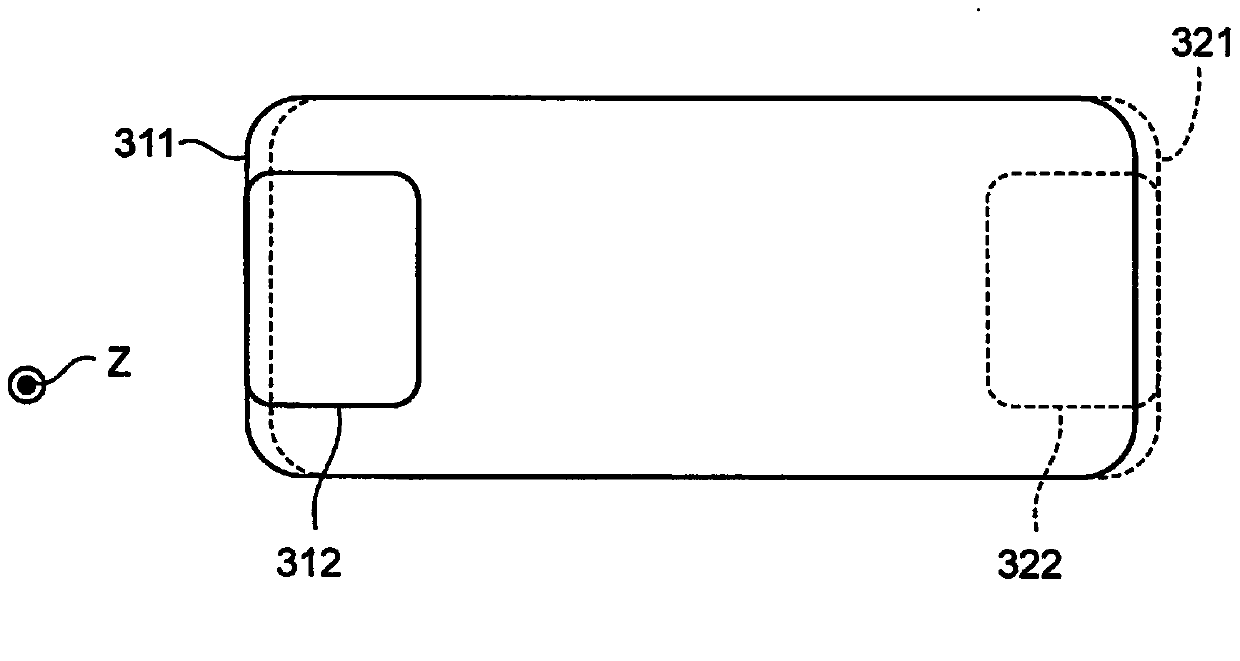

[0058] figure 1 It is a sectional view showing the first embodiment of the coil component of the present invention. figure 2 It is an exploded perspective view of the coil part. Such as figure 1 as well as figure 2As shown, the coil component 10 includes: a magnetic core 3 having a closed magnetic circuit structure; a primary side coil 1 wound around the magnetic core 3; and a secondary side coil 2 wound around the magnetic core 3 and disposed on the primary side. The axial direction of the side coil 1 and is magnetically coupled with the primary side coil 1 . The coil component 10 is used, for example, as a power filter choke coil (power choke coil). Primary side coil 1 and secondary side coil 2 are covered with insulating resin 4 . The insulating resin 4 is covered with the magnetic core 3 . Let the axial direction of the primary side coil 1 be a Z-axis direction. exist figure 1 The primary side coil 1 is shown by a solid line, and the secondary side coil 2 is show...

no. 2 approach

[0081] Figure 4 It is a sectional view showing the second embodiment of the coil component of the present invention. Figure 5 It is an exploded perspective view of the coil part. The second embodiment differs from the first embodiment in the configuration of the second coil portion of the primary side coil and the secondary side coil. Only this different structure will be described below. In addition, in the second embodiment, the same reference numerals as those in the first embodiment denote the same structures as those in the first embodiment, and therefore description thereof will be omitted.

[0082] Such as Figure 4 and Figure 5 As shown, in the coil component 10A, the second coil portion 12A of the primary side coil 1A has a first helical portion 121 and a second helical portion 122 . The first helical part 121 and the second helical part 122 are stacked sequentially from the first coil part 11 in the Z-axis direction. The first spiral portion 121 and the seco...

no. 3 approach

[0089] Figure 6 It is a cross-sectional view showing a third embodiment of the coil component of the present invention. The third embodiment differs from the first embodiment in the positions of the second coil portions of the primary side coil and the secondary side coil. Only this different structure will be described below. In addition, in the third embodiment, the same reference numerals as those in the first embodiment denote the same structures as those in the first embodiment, and therefore description thereof will be omitted.

[0090] Such as Figure 6 As shown, in the coil component 10B, the second coil portion 12 of the primary side coil 1 and the second coil portion 22 of the secondary side coil 2 are located in the Z-axis direction. In the Z-axis direction, the second coil portion 12 of the primary side coil 1 is located between the first coil portion 21 and the second coil portion 22 of the secondary side coil 2, and the second coil portion 22 of the secondary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com