Working vehicle

A technology for working vehicles and wheels, which is applied to vehicle parts, agriculture, wheels, etc., can solve the problems of lugs entraining soil and the decline of wet field passability, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

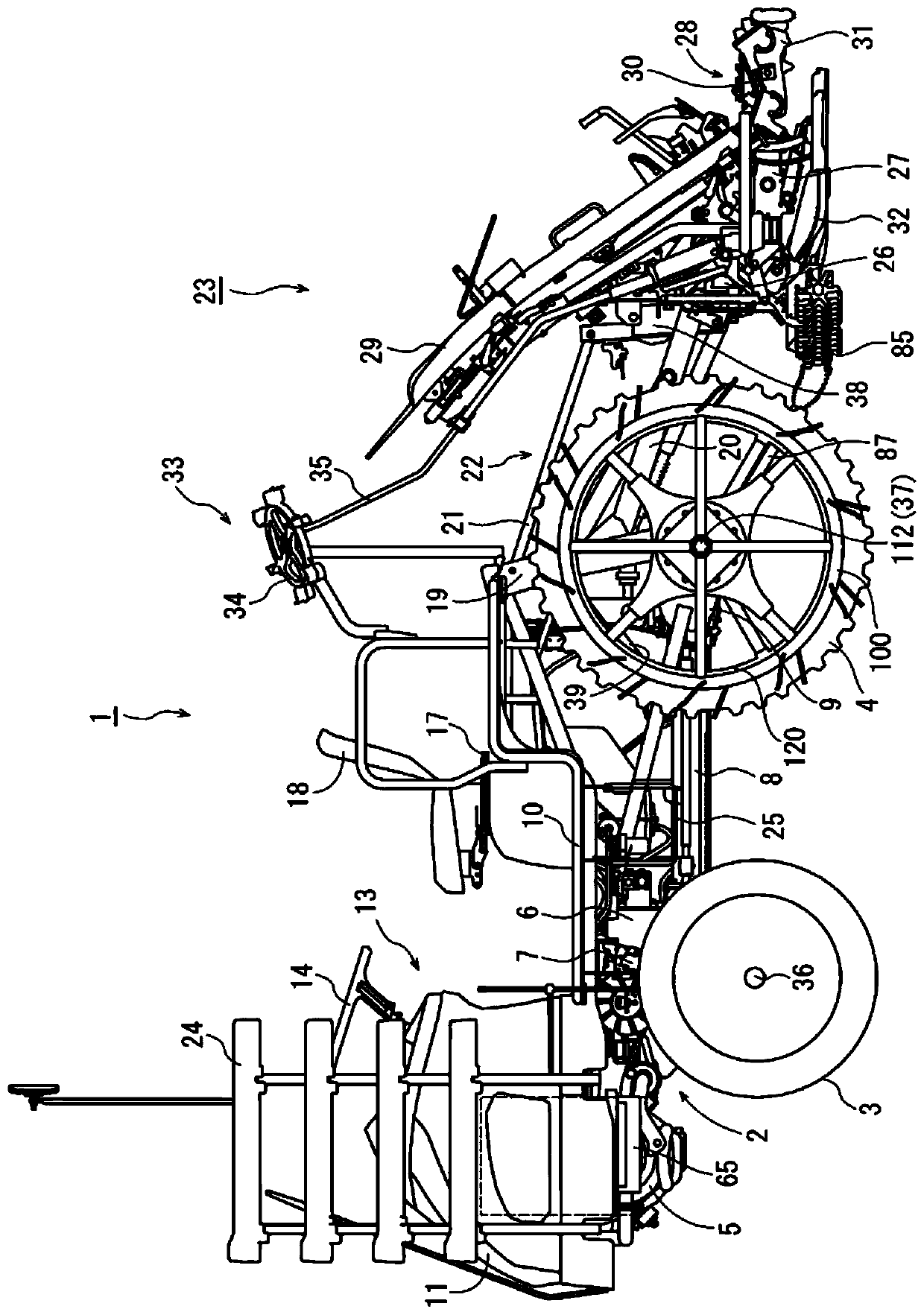

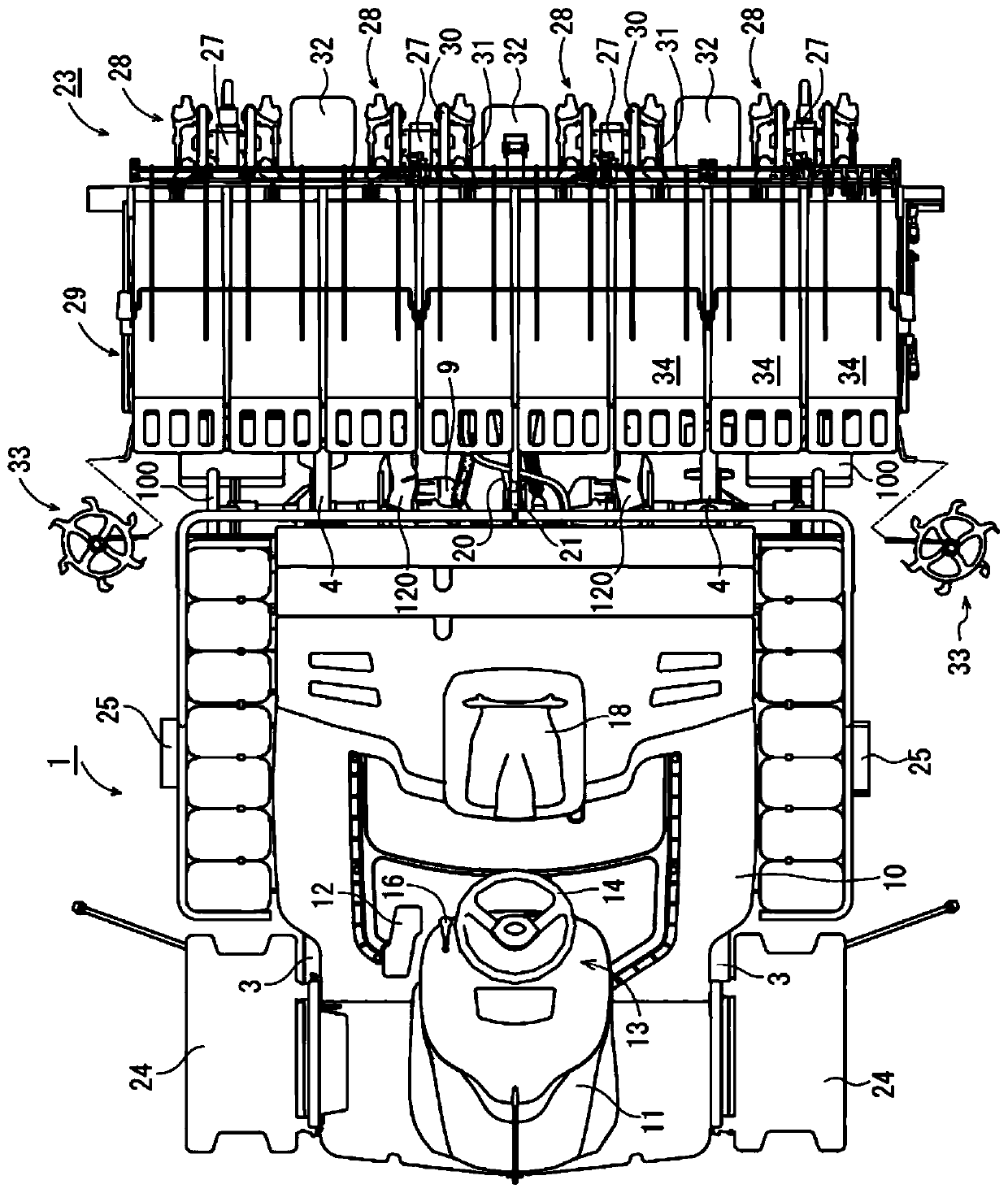

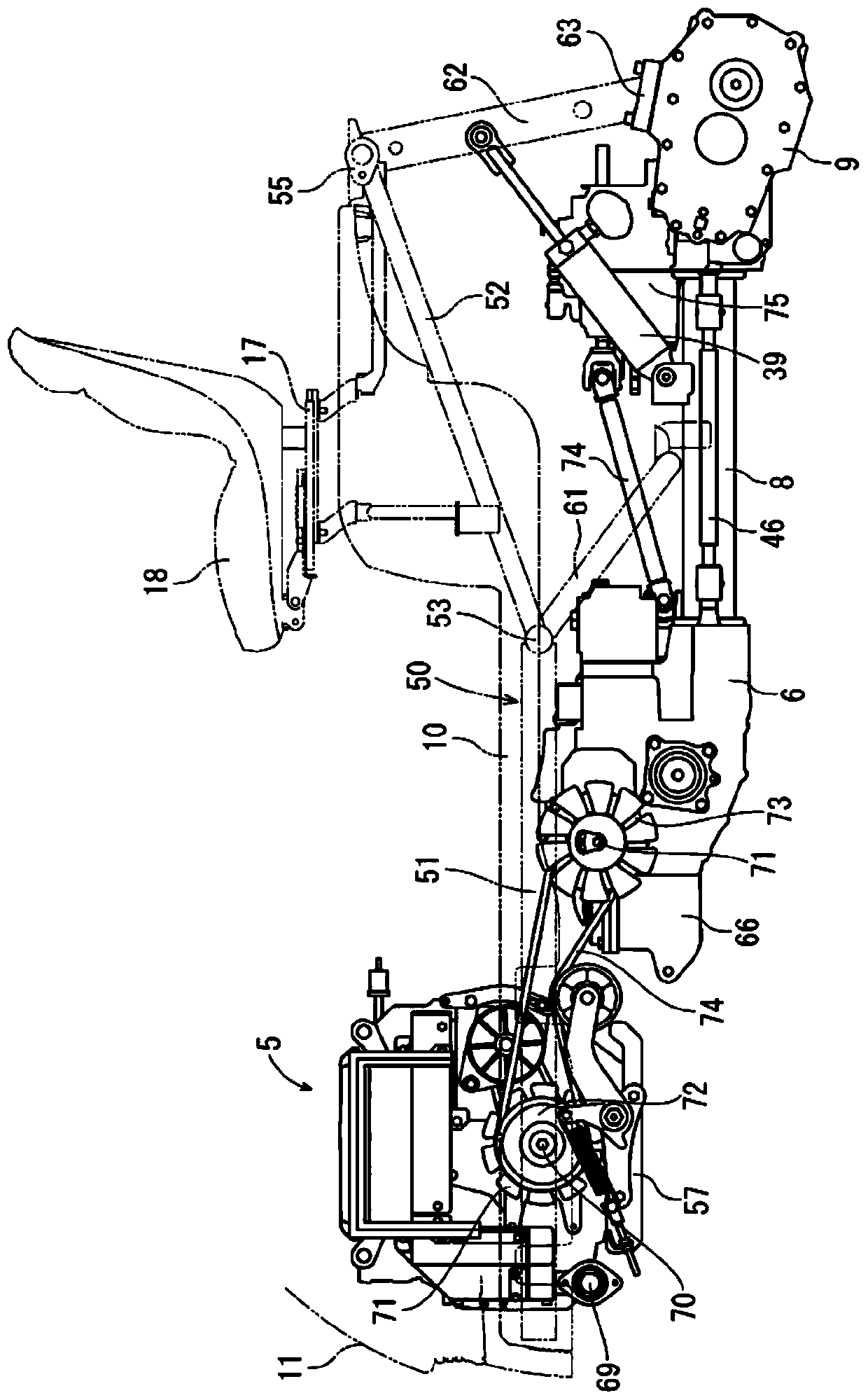

[0025] Hereinafter, the specific embodiment of this invention is demonstrated based on the drawing applied to the riding-type rice transplanter 1 (henceforth abbreviated as the rice transplanter 1) of an eight-row transplanting type. It should be noted that, in the following description, the left side when facing the traveling direction of the traveling body 2 is simply referred to as the left side, and the right side when facing the traveling direction is also simply referred to as the right side.

[0026] First, refer to Figure 1 ~ Figure 4 The outline|summary of the rice transplanter 1 is demonstrated. The rice transplanter 1 of embodiment is equipped with the traveling body 2 supported by the front wheel 3 of a pair of right and left which is a traveling wheel, and the rear wheel 4 of a pair of left and right similarly. An engine 5 is mounted on the front portion of the traveling body 2 . It is configured to drive the front wheels 3 and the rear wheels 4 by transmitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com