Method for deeply burying straw and ploughing by applying straw harvesting and crushing ditch collection deep bury ploughing device

A straw and ditch-collecting technology, which is applied in applications, harvesters, cutters, etc., can solve the problems of low utilization rate of straw, environmental pollution, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

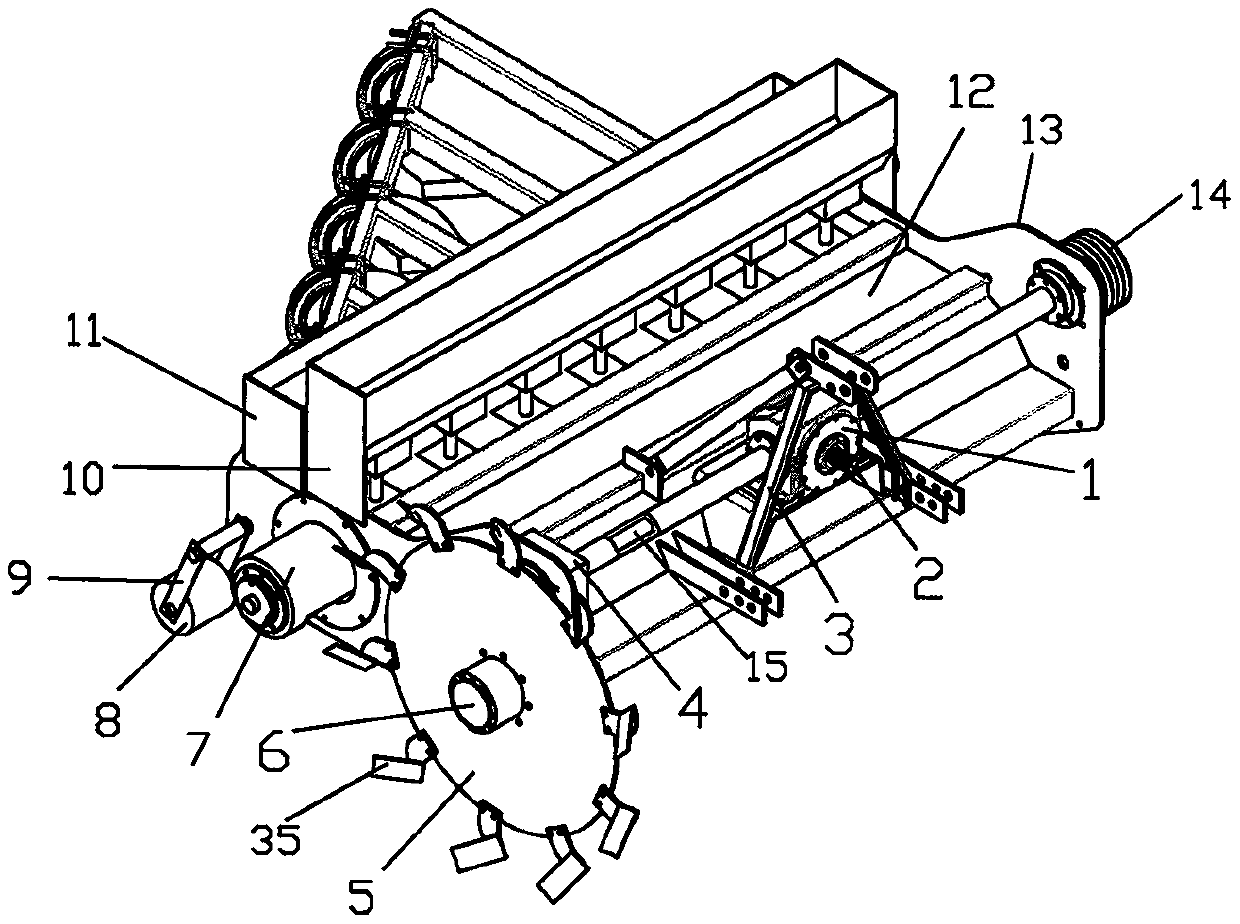

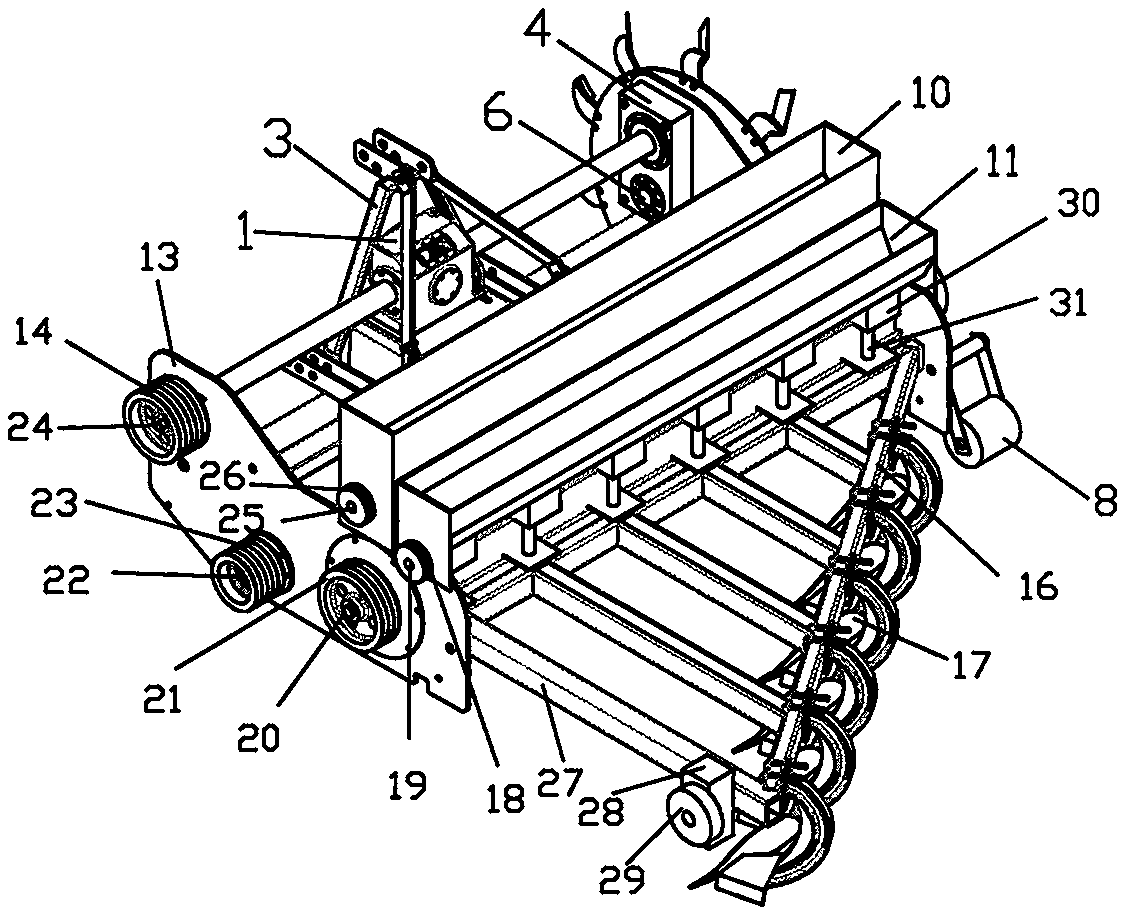

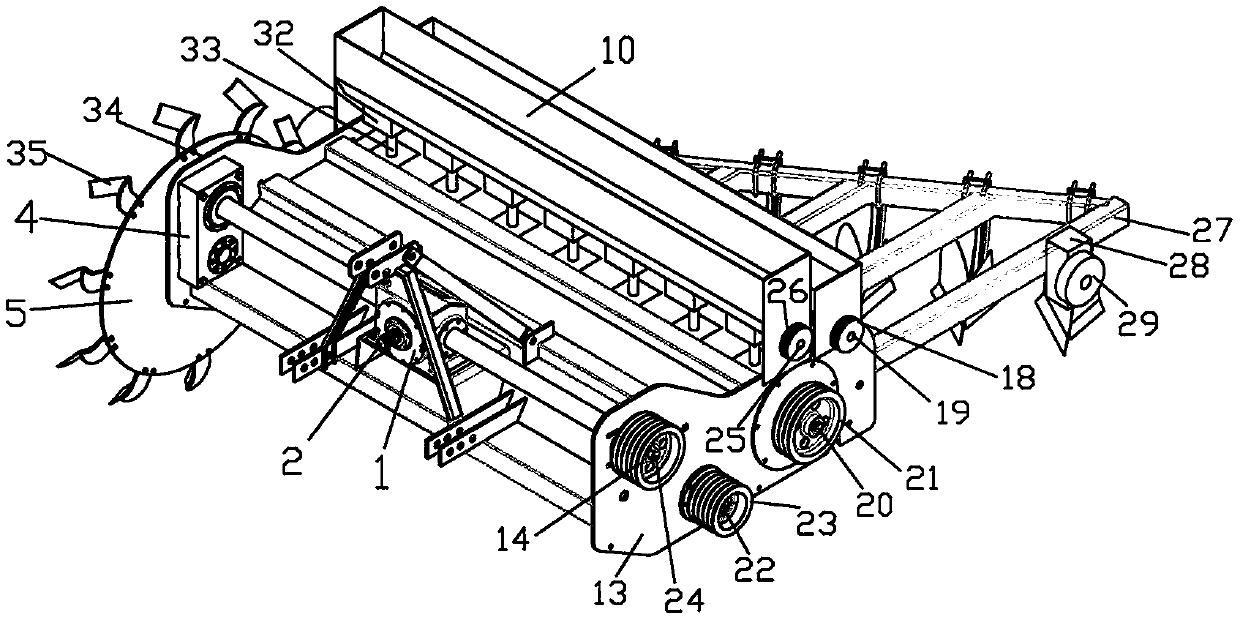

[0029] Embodiment 1: as Figure 1-Figure 7As shown, the straw harvesting and crushing ditch deep-buried plowing device includes a tractor, a suspension frame, a power output shaft, and a harvesting and crushing chamber fixedly connected by a left side plate 13, an upper cover plate 12, and a right side plate 34. The front part of the cover plate 12 is fixedly connected with the reduction box 1 and the traction frame 3, the traction frame 3 is connected with the suspension of the tractor, the power input shaft 2 of the reduction box is connected with the power output shaft of the tractor through a universal joint transmission; the right side plate 34 The top is fixedly connected with the ditching reduction box 4, and the power input shaft of the ditching reduction box 4 is connected to the first power output shaft 15 of the reduction box. The ditching blade 35 is fixedly connected to the disk 5, and the ditching blade 35 is inclined to the outside; the left side plate 13 is rot...

Embodiment 2

[0042] Embodiment 2: The structure of embodiment 2 is basically the same as that of embodiment 1, except that the width of the ditching blade is 28CM, the ditching depth H1 is 38CM during plowing operation, and the plowing depth H2 is 20CM.

[0043] The method of using the straw harvesting and crushing collection ditch deep burying plowing device to bury the straw plowing is basically the same as the method in Example 1, the difference is that in step (2) in the ditching of the cutter head, the plowing is deeply buried in the straw harvesting and crushing collection ditch. On the right side of the device, a trench with a width of 28CM and a depth of 38CM is excavated; in step (8) plowing the land to seal the ditch, the plowshare fixed on the inclined beam of the plow frame will turn the land 18CM deep,

Embodiment 3

[0044] Embodiment 3: The structure of embodiment 3 is basically the same as that of embodiment 1, except that the width of the ditching blade is 30CM, the ditching depth H1 is 40CM during plowing operation, and the plowing depth H2 is 23CM.

[0045] The method of using the straw harvesting and crushing collection ditch deep burying plowing device to bury the straw plowing is basically the same as the method in Example 1, the difference is that in step (2) in the ditching of the cutter head, the plowing is deeply buried in the straw harvesting and crushing collection ditch. A trench with a width of 30 cm and a depth of 40 cm is excavated on the right side of the device; in step (8) plowing the land to seal the ditch, the plowshares fixed on the inclined beam of the plow frame will plow the land by 23 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com