Welding method for small airborne rocket case

A technology of a rocket shell and a welding method, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high processing efficiency, the excess height cannot be greater than 0.3mm, and the manufacturing cost is low, and achieves fast and accurate installation and positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

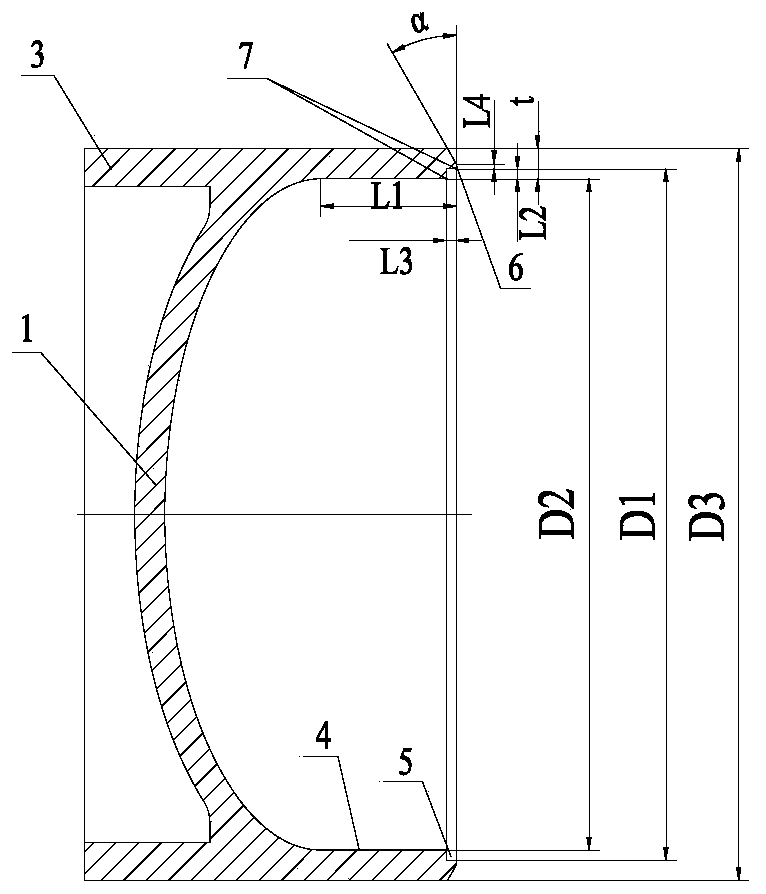

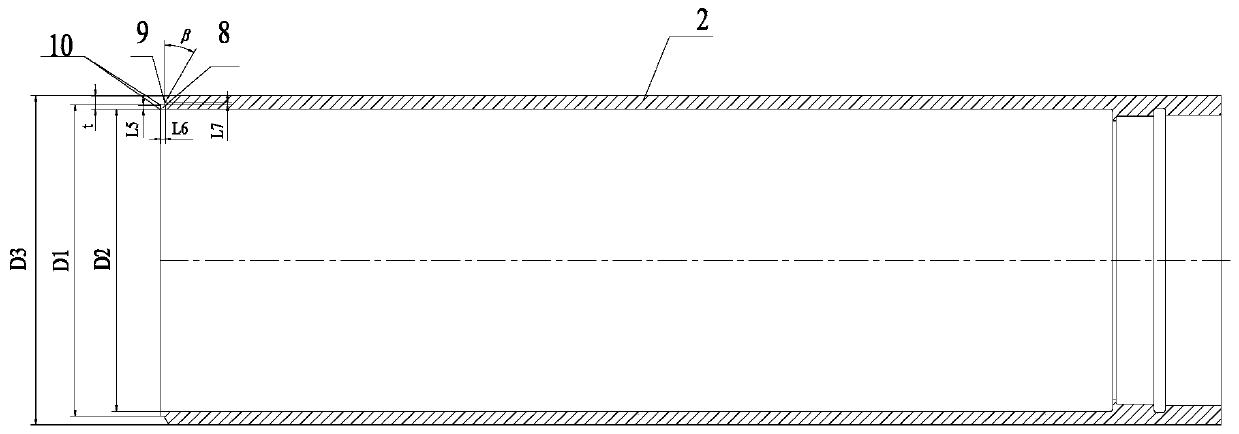

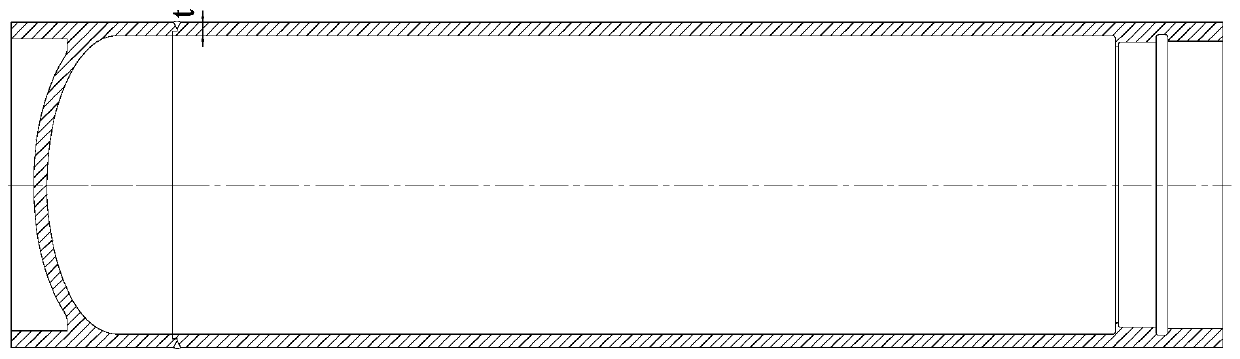

[0060] For a certain type of 30CrMnSiA low-alloy high-strength steel small shell, its external diameter D3 is 140mm, shell length L0 is 550mm, and wall thickness t is 2mm. The airborne small rocket shell welding method of the present invention is as follows:

[0061] 1) Processing of the front head shell and the rear joint shell of the cylinder

[0062] The raw material of the cylinder is roughly machined into the front head shell, the front end of the front head shell is provided with a finishing chuck, and the rear end of the front head shell is provided with a front circle which is butt-welded with the rear joint shell of the cylinder. and the rear end of the inner wall of the front cylinder section is provided with a front positioning annular notch, the rear end face of the front cylinder section is provided with a front bevel, and the inner edge of the front bevel is perpendicular to the surface between the end faces of the front positioning annular notch. The front butt ...

Embodiment 2

[0080] For a certain type of 30CrMnSiA low-alloy high-strength steel small shell, its external diameter D3 is 180mm, shell length L0 is 850mm, and wall thickness t is 2.5mm. The airborne small rocket shell welding method of the present invention is as follows:

[0081] 1) Processing of the front head shell and the rear joint shell of the cylinder

[0082] The raw material of the cylinder is roughly machined into the front head shell, the front end of the front head shell is provided with a finishing chuck, and the rear end of the front head shell is provided with a front circle which is butt-welded with the rear joint shell of the cylinder. and the rear end of the inner wall of the front cylinder section is provided with a front positioning annular notch, the rear end face of the front cylinder section is provided with a front bevel, and the inner edge of the front bevel is perpendicular to the surface between the end faces of the front positioning annular notch. The front but...

Embodiment 3

[0100] For a certain model 30CrMnSiA low-alloy high-strength steel small shell, its external diameter D3 is 220mm, the shell length L0 is 1150mm, and the wall thickness t is 3mm. The airborne small rocket shell welding method of the present invention is as follows:

[0101] 1) Processing of the front head shell and the rear joint shell of the cylinder

[0102] The raw material of the cylinder is roughly machined into the front head shell, the front end of the front head shell is provided with a finishing chuck, and the rear end of the front head shell is provided with a front circle which is butt-welded with the rear joint shell of the cylinder. and the rear end of the inner wall of the front cylinder section is provided with a front positioning annular notch, the rear end face of the front cylinder section is provided with a front bevel, and the inner edge of the front bevel is perpendicular to the surface between the end faces of the front positioning annular notch. The fron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com